Preparation method of cerium dioxide polishing powder liquid

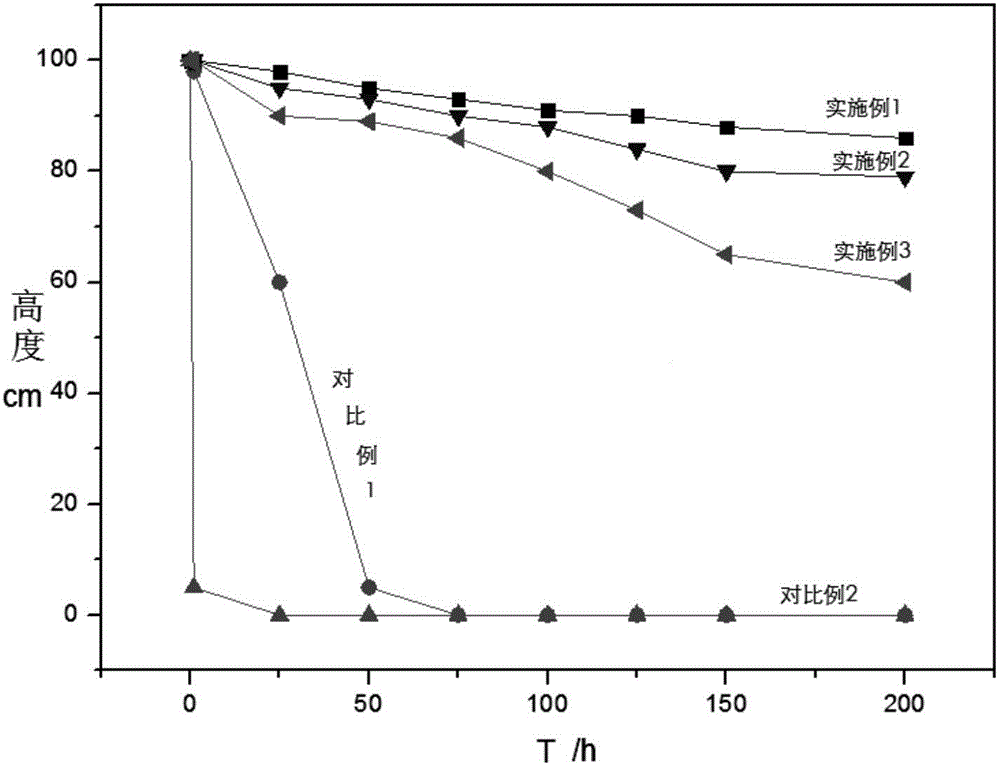

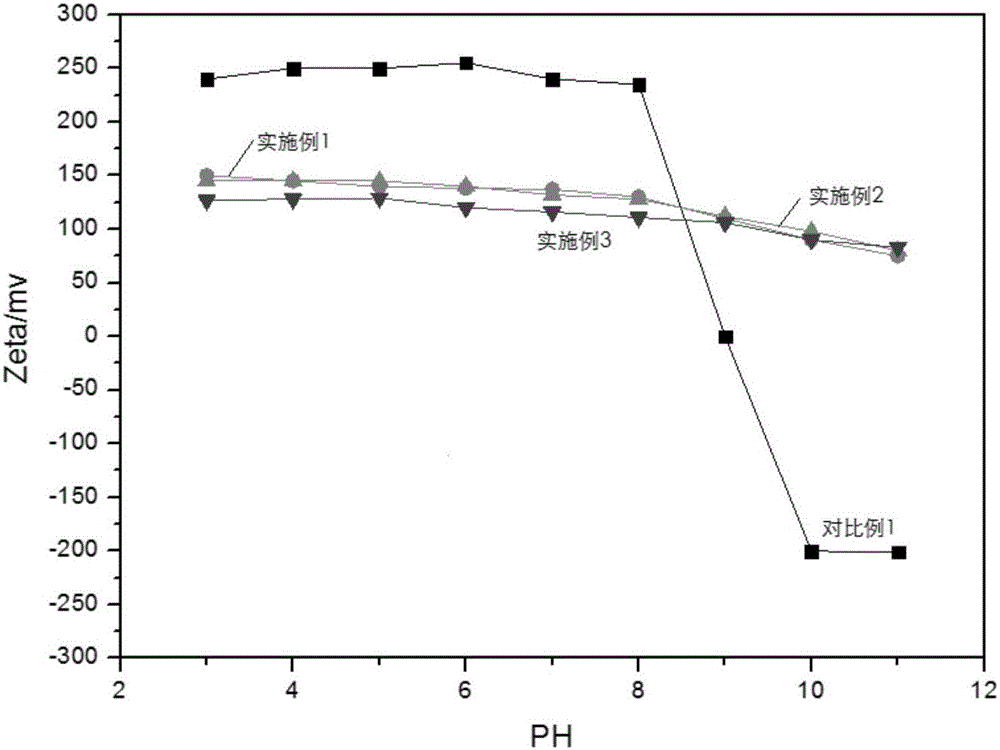

A technology of cerium dioxide and polishing liquid, which is applied in chemical instruments and methods, polishing compositions containing abrasives, and other chemical processes, can solve problems such as short time, reduced grinding efficiency, and poor stability, and is not easy to achieve Sedimentation, effect of long suspension time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 2g of cerium oxide powder and 0.8g of N-3-trimethoxysilylpropyl ethylenediamine into 100ml of ethanol solution containing 99% by volume, and mix the mixture, and place the mixture in an ultrasonic bath for 10 minutes of ultrasound, then in 70 Stir in a water bath at ℃ for 120 min, then dehydrated and filtered, washed with sewage ethanol three times, and dried in an oven at 80 ℃ to obtain a powder sample.

Embodiment 2

[0023] Add 2g of cerium oxide powder and 1.0g of N-3-trimethoxysilylpropyl ethylenediamine to 100ml of ethanol solution containing 95% by volume and mix, and place the mixed solution in an ultrasonic bath for 10 minutes, and then in 70 Stir in a water bath at ℃ for 120 min, then dehydrated and filtered, washed with sewage ethanol three times, and dried in an oven at 80 ℃ to obtain a powder sample.

Embodiment 3

[0025] Add 2g of cerium oxide powder and 2g of N-3-trimethoxysilylpropyl ethylenediamine to 100ml of ethanol solution containing 50% by volume and mix, and place the mixed solution in an ultrasonic bath for 10 minutes, then at 70°C Stir in a water bath for 120 minutes, then dehydrated and filtered, washed with sewage ethanol three times, and dried in an oven at 80°C to obtain a powder sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com