Method for conducting bacterial oxidation treatment on gold tailings and recycling gold in gold tailings through cyaniding

A technology for bacterial oxidation and gold tailings, applied in the direction of improving process efficiency, can solve the problem of little research on comprehensive recovery and utilization of tailings resources, and achieve the effects of easy bacterial oxidation, simple operation, and reduction of environmental risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

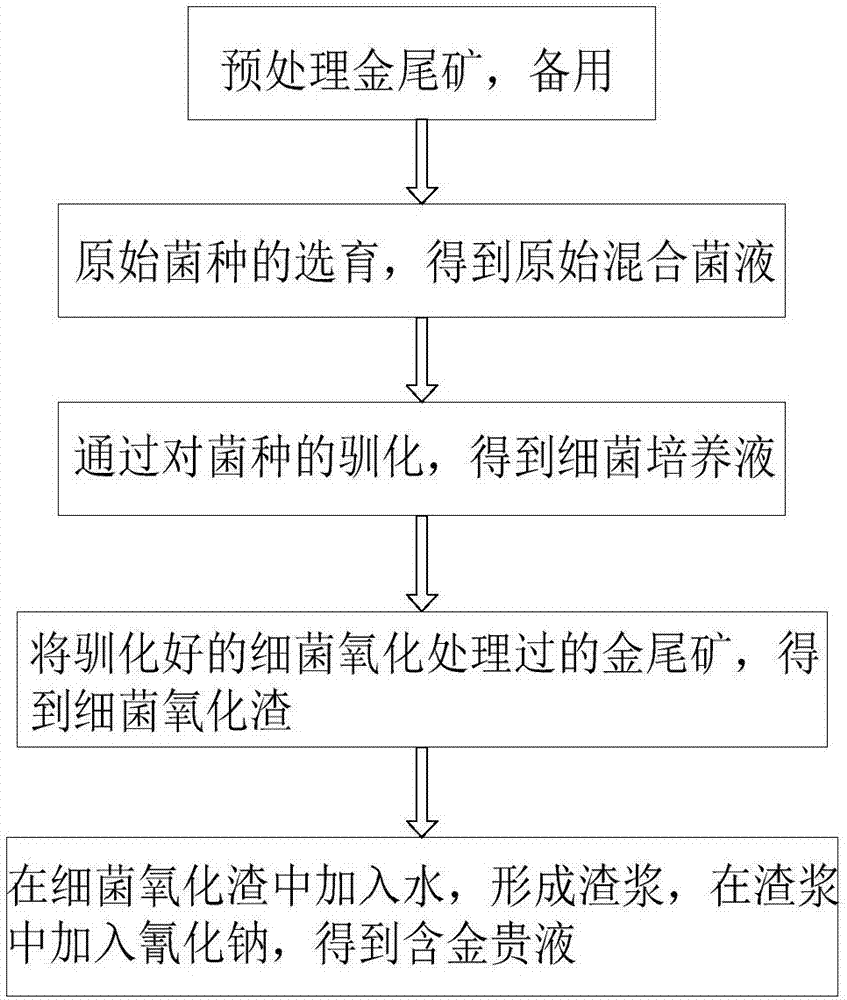

[0047] The invention provides a method for bacteria oxidation treatment of gold tailings-cyanidation recovery of gold in the tailings, comprising the following steps:

[0048] Step 1, pretreatment of gold tailings: the tailings collected from the gold tailings pond do not need to be ground, and are directly washed with tap water for 2 to 4 times, and then the washed gold tailings are soaked in dilute sulfuric acid with a pH of 2 In the solution for 12 to 36 hours, the pretreated gold tailings are obtained and set aside;

[0049] Step 2, the selection of original strains: put the acid mine mud water and 9K culture medium collected from the gold tailing pond into the triangular flask sterilized by an autoclave at a volume ratio of 1:10, and then put Cultivate in a shaker at a temperature of 30-55°C, fill with air and stir, and the air volume is 0.2m 3 / h, the rotation speed of the shaking table is 180rpm, after 7 days of cultivation, select the culture flask whose color changes...

Embodiment 2

[0061] The invention provides a method for bacteria oxidation treatment of gold tailings-cyanidation recovery of gold in the tailings, comprising the following steps:

[0062] Step 1, pretreatment of gold tailings: the tailings collected from the gold tailings pond do not need to be ground, and are directly washed with tap water for 2 to 4 times, and then the washed gold tailings are soaked in dilute sulfuric acid with a pH of 2 In the solution for 12 to 36 hours, the pretreated gold tailings are obtained and set aside;

[0063] Step 2, the selection of original strains: put the acid mine mud water and 9K culture medium collected from the gold tailing pond into the triangular flask sterilized by an autoclave at a volume ratio of 1:10, and then put Cultivate in a shaker at a temperature of 30-55°C, fill with air and stir, and the air volume is 0.2m 3 / h, the rotation speed of the shaking table is 180rpm, after 7 days of cultivation, select the culture flask whose color changes...

Embodiment 3

[0075] The invention provides a method for bacteria oxidation treatment of gold tailings-cyanidation recovery of gold in the tailings, comprising the following steps:

[0076] Step 1, pretreatment of gold tailings: the tailings collected from the gold tailings pond do not need to be ground, and are directly washed with tap water for 2 to 4 times, and then the washed gold tailings are soaked in dilute sulfuric acid with a pH of 2 In the solution for 12 to 36 hours, the pretreated gold tailings are obtained and set aside;

[0077] Step 2, the selection of original strains: put the acid mine mud water and 9K culture medium collected from the gold tailing pond into the triangular flask sterilized by an autoclave at a volume ratio of 1:10, and then put Cultivate in a shaker at a temperature of 30-55°C, fill with air and stir, and the air volume is 0.2m 3 / h, the rotation speed of the shaking table is 180rpm, after 7 days of cultivation, select the culture flask whose color changes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com