Printing and dyeing auxiliary, printing and dyeing ink for textile and integrated device and preparation method thereof

A printing and dyeing auxiliaries and textile technology, applied in the field of textile printing and dyeing, can solve the problems of unsolved dyeing rate of fabrics, level dyeing of bright fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

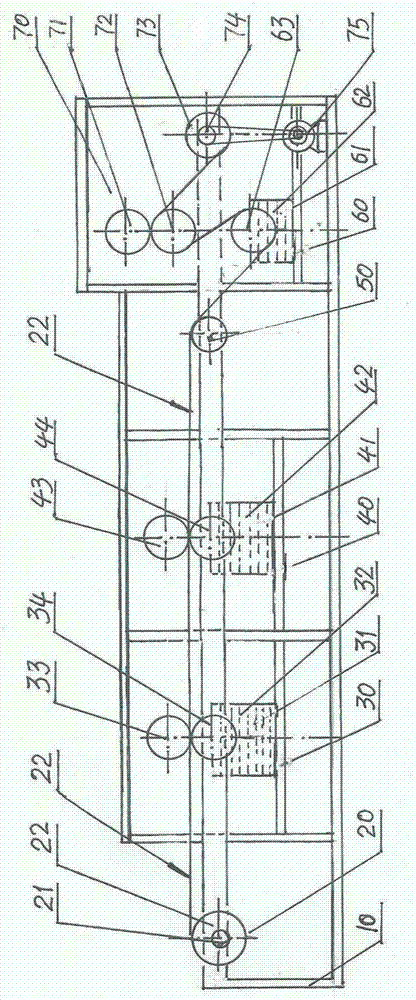

Image

Examples

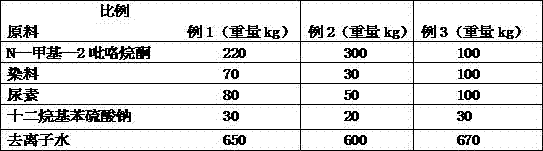

Embodiment 1

[0090] Method for preparing 1000 kg textile printing and dyeing auxiliaries at one time:

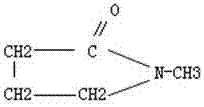

[0091] Step 1: weigh N-methyl-2 pyrrolidone 220%, dyestuff 70%, urea 80%, sodium dodecylbenzene sulfate 30% and deionized water 650% of the present invention by weight percentage respectively Weight, respectively put into their respective containers, standby;

[0092] Step 2: Put 220% of N-methyl-2-pyrrolidone and 70% of the dyestuff used in step 1 into a stirring container, stir and mix evenly, let stand, and set aside;

[0093] Step 3: 80% of urea, 30% of sodium dodecylbenzene sulfate and 650% of deionized water are prepared in step 1. Put the spare N-methyl-2-pyrrolidone and the dyestuff in the stirring vessel used in step 2, stir and mix evenly, and then filter to obtain the finished textile printing and dyeing auxiliaries.

Embodiment 2

[0095] Method for preparing 1000 kg textile printing and dyeing auxiliaries at one time:

[0096] Step 1: weigh N-methyl-2 pyrrolidone 300% of the present invention, dyestuff 30%, urea 50%, sodium dodecylbenzene sulfate 20% and deionized water 600% by weight percentage respectively Weight, respectively put into their respective containers, standby;

[0097] Step 2: Put 300% of N-methyl-2-pyrrolidone and 30% of the dye used in step 1 into a stirring container, stir and mix evenly, then let stand and set aside;

[0098] Step 3: 50% of urea, 20% of sodium dodecylbenzene sulfate and 600% of deionized water are prepared in Step 1. Put the spare N-methyl-2-pyrrolidone and the dyestuff in the stirring vessel used in step 2, stir and mix evenly, and then filter to obtain the finished textile printing and dyeing auxiliaries.

Embodiment 3

[0100] Method for preparing 1000 kg textile printing and dyeing auxiliaries at one time:

[0101] Step 1: weigh N-methyl-2 pyrrolidone 100% of the present invention, dyestuff 100%, urea 100%, sodium dodecylbenzene sulfate 30% and deionized water 670% by weight percentage respectively Weight, respectively put into their respective containers, standby;

[0102] Step 2: Put 100% N-methyl-2-pyrrolidone and 100% dyestuff used in Step 1 into a stirring container, stir and mix evenly, then let stand and set aside;

[0103]Step 3: 100% urea, 30% sodium dodecylbenzene sulfate and 670% deionized water used in step 1 are prepared. Put the spare N-methyl-2-pyrrolidone and the dyestuff in the stirring vessel used in step 2, stir and mix evenly, and then filter to obtain the finished textile printing and dyeing auxiliaries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com