Method for power generation through coal underground gasified product gas

A technology for underground gasification and product gas, applied in coal gasification, underground mining, combustible gas purification, etc., can solve problems such as lack of process plan, and achieve the effect of reducing costs, increasing production and sales revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

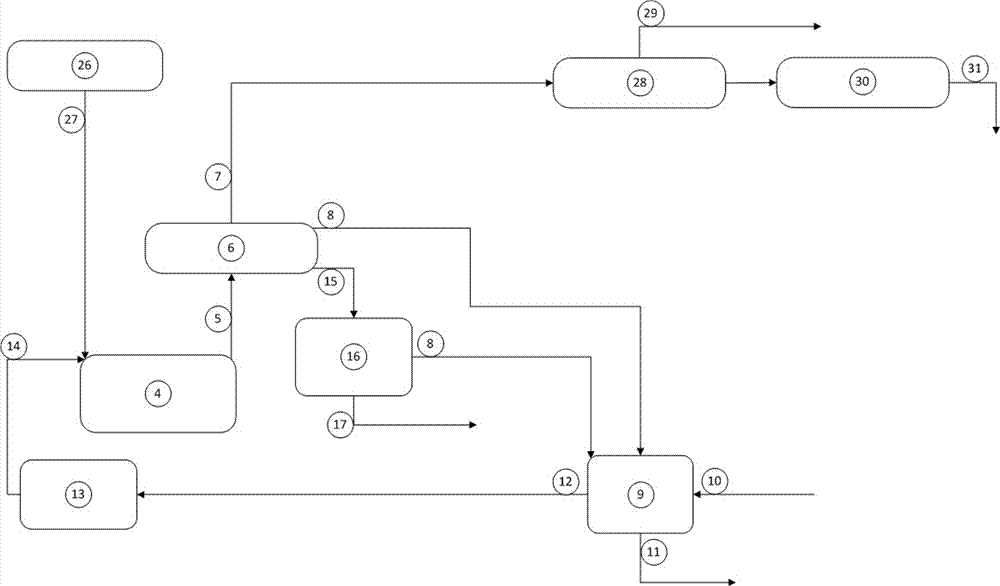

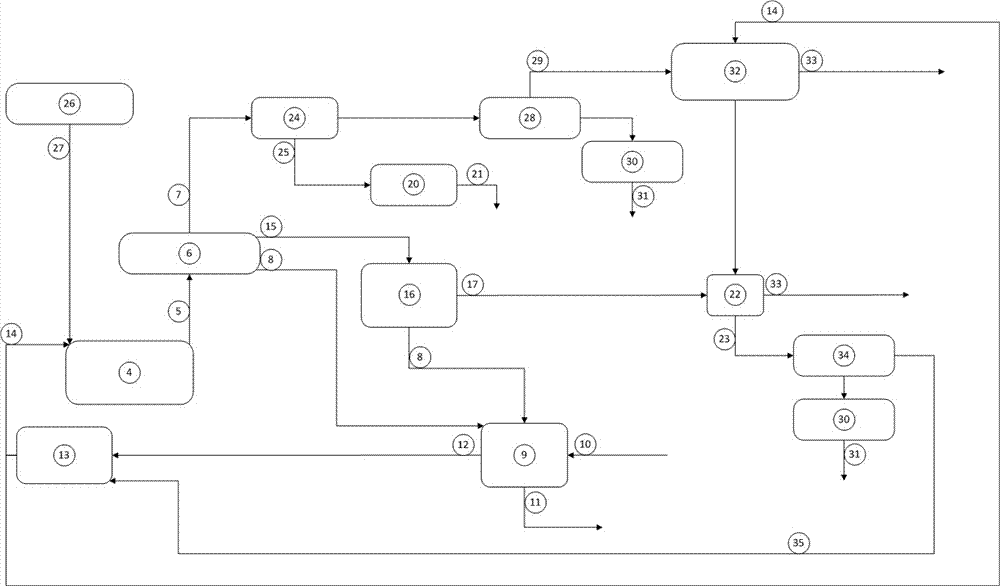

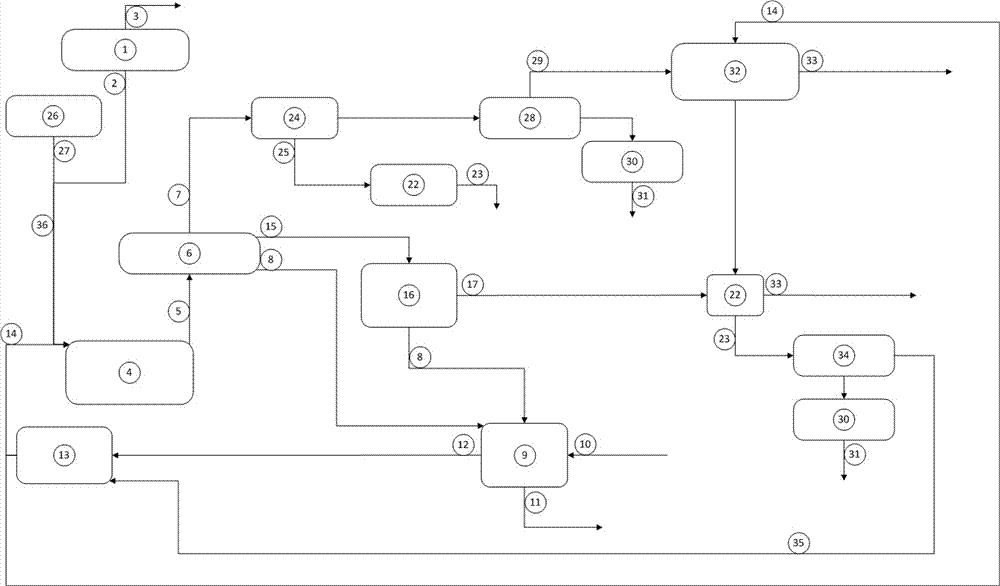

[0040] In one embodiment, underground coal gasification product gas is used to generate electricity. For coal seams with high calorific value (LHV>24MJ / kg) with ultra-low sulfur content, chlorine content, phosphorus content and heavy metal content, dry syngas7 can be directly used for power generation without additional treatment ( figure 1 ). The process can use air gasification, oxygen-enriched gasification or pure oxygen gasification. The synthetic gas produced by air gasification has a low calorific value, 4-6MJ / Nm3 ; The synthetic gas produced by pure oxygen oxidation has a high calorific value, 10-12MJ / Nm 3 . The main difference is the inert component N in the synthesis gas 2 The content of N in air gasification syngas 2 The content can be as high as 50mole%, and the N in the pure oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com