Method for detecting overheating treatment of vegetable oil, and use of method

A technology of overheating and vegetable oil, applied in the field of food safety, can solve problems such as adverse human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

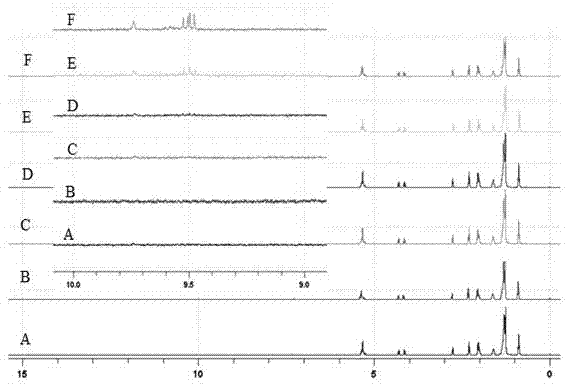

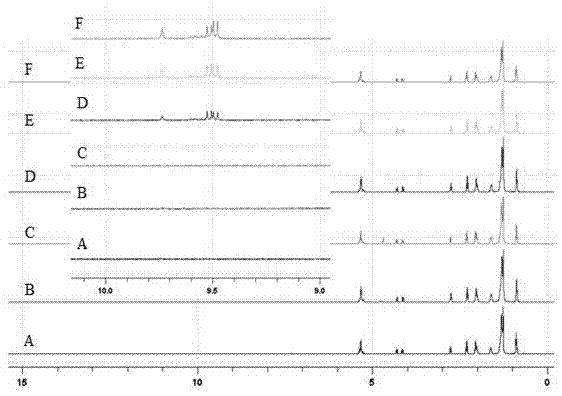

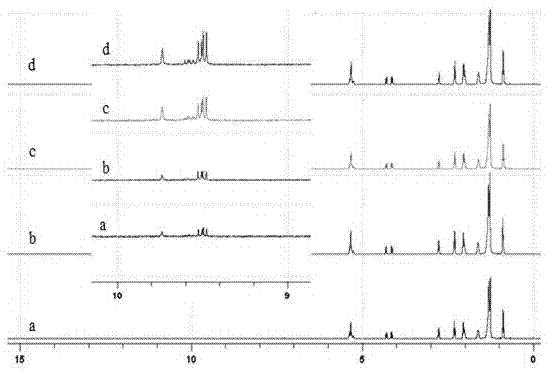

[0053] Take 100 μL of corn germ oil sample with a pipette gun, add 400 μL of deuterated chloroform, shake well, put it into an NMR tube, and test 1 H-NMR spectrum. 1 H-NMR spectrum measurement method: time domain 32K, 90 pulse time: 14.4μs, spectral width: 20ppm, relaxation: 1s, signal detection time: 4.09s, number of scans per free induction decay: 8, number of virtual scans: 8 . Chemical shifts are in ppm, using deuterated chloroform (CDCL3) as solvent and 1% tetramethylsilane (TMS, d=0) as internal standard. 1 H-NMR spectrum data processing: application Bruker TOPSPIN 2.1 software, in 1 In the H-NMR spectrum, the phase is adjusted, and TMS, d=0 is used for calibration. Test result: not found in 1 In the H-NMR spectrum, the characteristic signal of aldehyde group hydrogen appears between δH=9.0 and 10.0 in the low field region (see figure 2 A).

Embodiment 2

[0055] Take 150mL of the same corn germ oil as in Example 1, heat and stir at a constant temperature of 170° C. for 2 hours to obtain heating oil.

[0056] Use a pipette gun to take 100 μL of a sample of corn germ oil that has been heated and stirred at 170 °C for 2 hours, add 400 μL of deuterated chloroform, shake well, put it into an NMR tube, and test 1 H-NMR spectrum. 1 H-NMR spectrum determination method: time domain 32K, 90 pulse time: 14.4μs, spectral width: 20ppm, relaxation: 1s, signal detection time: 4.09s, number of scans per free induction decay: 640, number of virtual scans: 2 . Chemical shifts are in ppm, using deuterated chloroform (CDCL3) as solvent and 0.1% tetramethylsilane (TMS, d=0) as internal standard. 1 H-NMR spectrum data processing: using Bruker TOPSPIN2.1 software, in 1 In the H-NMR spectrum, the phase is adjusted, and TMS, d=0 is used for calibration. Test results: found in 1 In the H-NMR spectrum, the characteristic signal of aldehyde group hyd...

Embodiment 3

[0058] Take 150 mL corn germ oil same as in Example 1, heat and stir at 170° C. for 2 hours, add 0.3 g of activated carbon, stir in a water bath at 40° C. for 30 minutes to decolorize, and filter with suction (a layer of diatomaceous earth is spread on the filter paper). The heated decolorized oil is obtained.

[0059] Use a pipette gun to take 400 μL of corn germ oil sample that has been heated and stirred at 170°C for 2 hours and decolorized, add 40 μL of deuterated chloroform, shake well, put it into an NMR tube, and test 1 H-NMR spectrum. 1 H-NMR spectrum determination method: time domain 32K, 90 pulse time: 14.4μs, spectral width: 20ppm, relaxation: 1s, signal detection time: 4.09s, number of scans per free induction decay: 64, number of virtual scans: 64 . Chemical shifts are in ppm, using deuterated chloroform (CDCL3) as solvent and 0.1% tetramethylsilane (TMS, d=0) as internal standard. 1 H-NMR spectrum data processing: application Bruker TOPSPIN 2.1 software, in 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com