Homogeneous 'scintillator-semiconductor-scintillator' composite X-ray detector

A technology of composite detectors and linear array detectors, which is applied in the field of sensors, can solve the problems of complex process and low efficiency, and achieve the effect of simple production method, single production principle and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

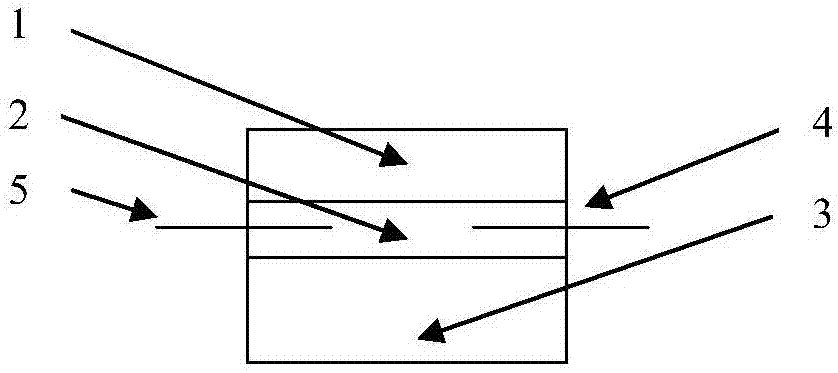

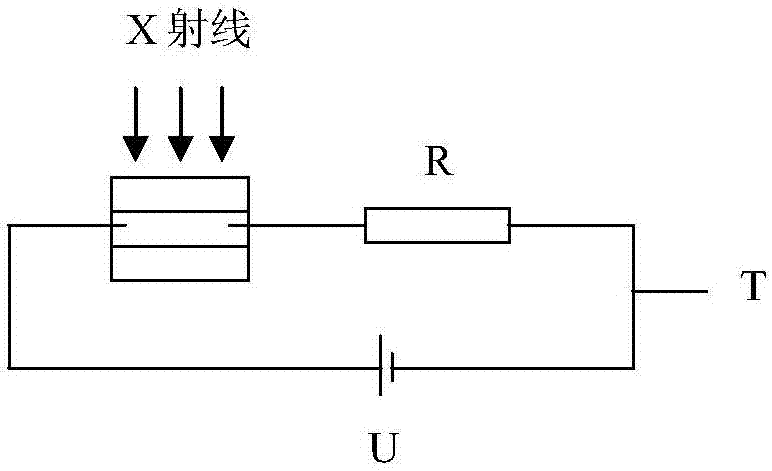

[0029] Such as figure 1 As shown, it includes a front scintillator 1, a semiconductor photoconductive detector, and a rear scintillator 3. The semiconductor photoconductive detector comprises a semiconductor substrate 2 (the substrate is not doped), an electrode one 4, an electrode two 5 and lead wires;

[0030] The same-substrate "scintillator-semiconductor-scintillator" composite X-ray detector can be obtained by general thin film growth techniques, such as magnetron sputtering or sol-gel method.

[0031] Take the magnetron sputtering method as an example:

[0032] First, prepare the target material of the matrix and the dopant substance. If ZnO is used as the matrix, Zn can be used as the matrix target material, and Ga or In is used as the dopant substance.

[0033] Using double-target magnetron sputtering equipment, first load two kinds of targets, fix two electrodes (such as interdigital electrodes) on the substrate, close the vacuum chamber, and start vacuuming.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com