Aerodynamics-based rice husk roller rubbing cleaning device

An aerodynamic and cleaning device technology, which is applied in the agricultural field, can solve problems such as the inability to clean and separate grain codes, the decline in grain cleaning rate, and insufficient material separation, and achieve a simple structure, prolonging the suspension time, and high cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the technical means, creative features and goals achieved by the present invention, the present invention is further described below in conjunction with the schematic diagrams, but the scope of protection claimed by the present invention is not limited to the scope described in the specific implementation.

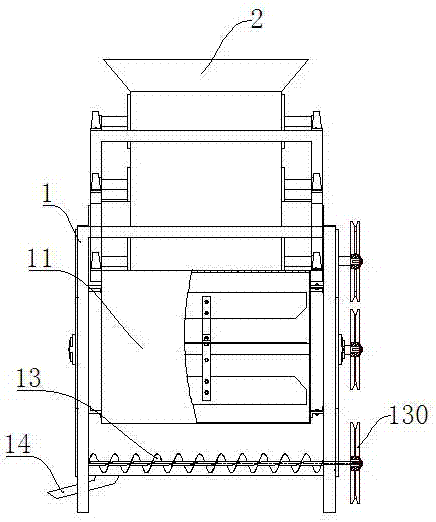

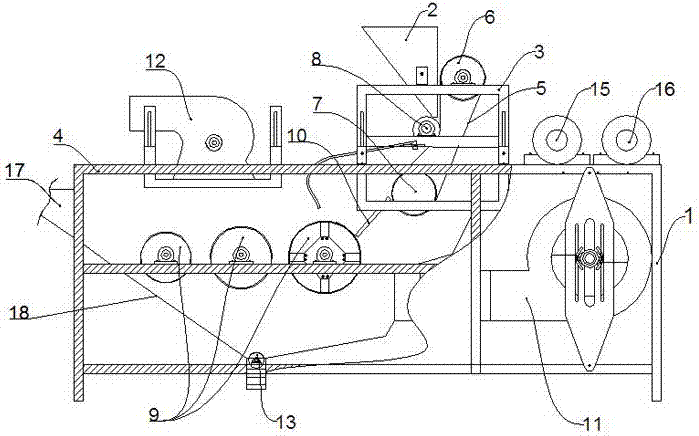

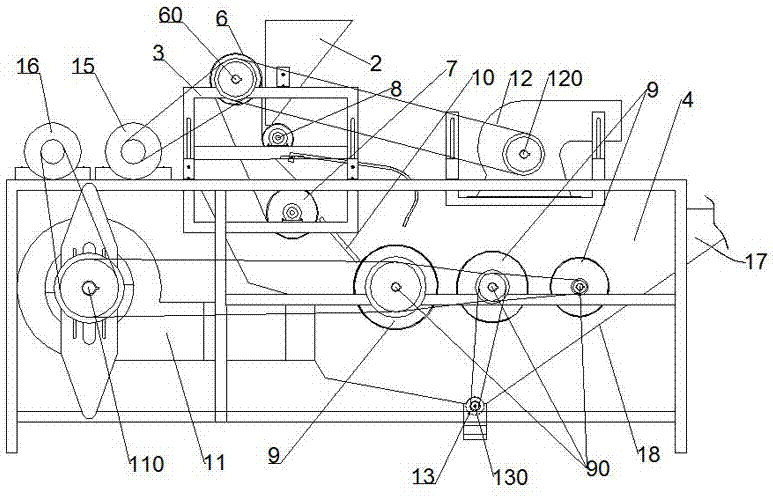

[0025] A kind of aerodynamics-based grain code roller rubbing cleaning device, such as figure 1 with figure 2 As shown, the device includes a frame 1, a feeding hopper 2, a grain collecting hopper 18, a grain threshing mechanism on the top of the frame 1, a separation mechanism below the grain threshing mechanism, and a grain conveying mechanism below the separation mechanism. mechanism. Wherein, grain yard threshing mechanism comprises belt 5, base 3 and upper belt roller 6 and lower belt roller 7 all installed on the base 3, and belt 5 walks around upper belt roller 6 and lower belt roller 7 to form a closed loop, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com