Flavor food drying/flavoring all-in-one machine

A food drying, all-in-one technology, used in food preservation, food forming, food science and other directions, can solve the problems of wasting seasoning liquid, incomplete taste, long existence time, etc., to improve product quality, shorten processing time, and easily The effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

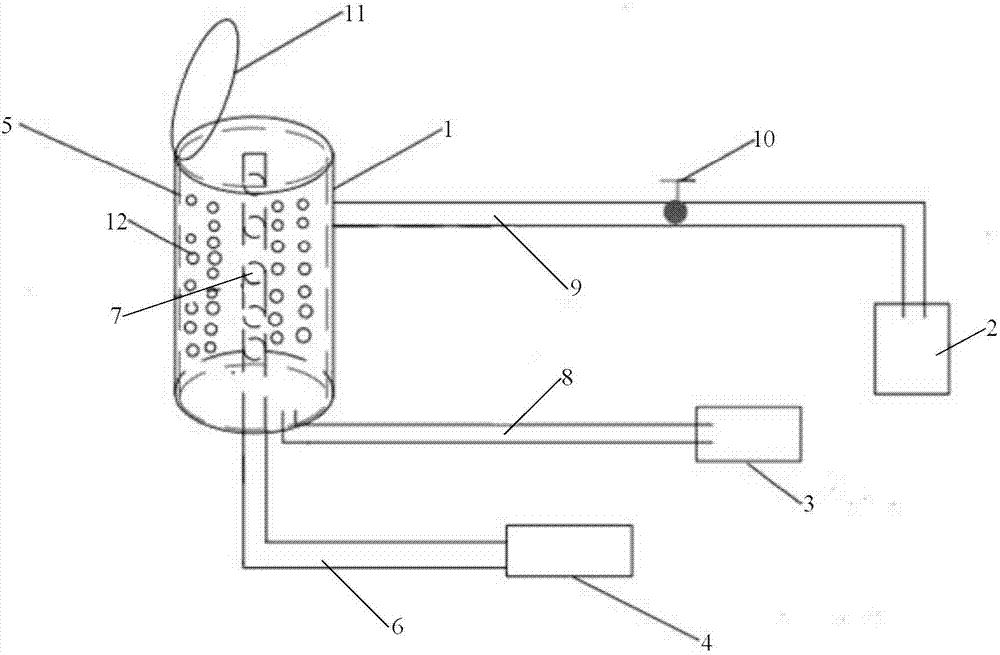

[0010] The embodiments will be described in detail below in conjunction with the accompanying drawings.

[0011] See attached figure 1 , a flavor food drying / tasting integrated machine, including a flavor food drying / tasting integrated machine, including a vacuum tank 1, a feed liquid tank 2, a vacuum pump 3, a hot air generator 4 and a hanging basket 5, the hot air generator 4 An air inlet pipe 6 is arranged on the top, one end of the air inlet pipe 6 is connected to the hot air generator 4, and the other end is connected to the vacuum tank 1, and the air inlet pipe 6 is provided with a hot air outlet 7 against the end of the vacuum tank 1, The hot blast that hot blast generator 4 produces is sent to hot air outlet 7 by air inlet pipe 6, then is sent in the vacuum tank 1; Described vacuum pump 3 is provided with air extraction pipe 8, and one end of described air extraction pipe 8 is connected with vacuum pump 3, and the other end is connected with vacuum pump 3. The vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com