Sinter-resistant low-cost catalysts manufactured by solution-based nanoparticle coating processes

A nanoparticle and catalyst technology, which is used in the field of preparing catalysts that resist sintering at high temperatures, can solve problems such as limited effectiveness

Inactive Publication Date: 2017-08-08

GM GLOBAL TECH OPERATIONS LLC

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these chemical treatment-based techniques lead to limited success

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

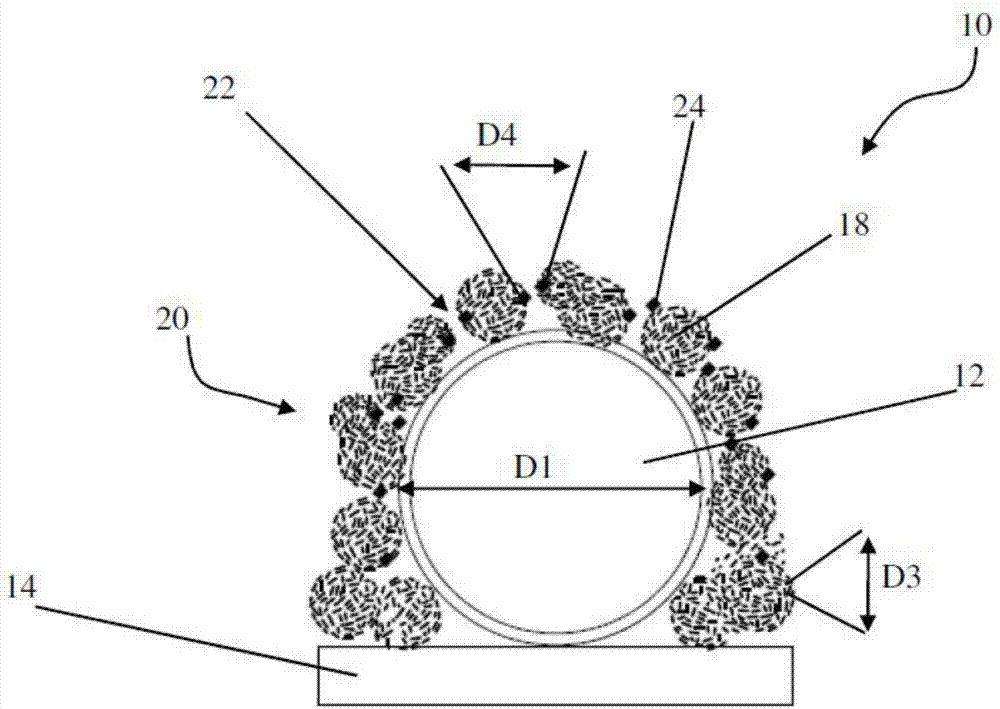

[0039] One includes binding to Al 2 o 3 (aluminum) carrier PGM nanoparticles powder loaded nanoparticles with Al 3+ aqueous solution in contact. The solution was dried at 150°C for 10 minutes to remove moisture, and then calcined at 500°C for 2 hours to form a solid surface on the loaded nanoparticles (referred to as "coated loaded nanoparticles"). Creates a porous aluminum coating.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

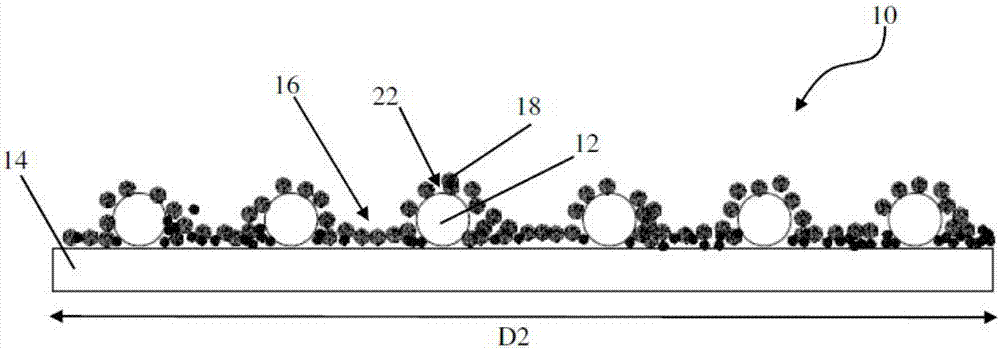

Catalysts that are resistant to high-temperature sintering and methods for preparing such catalysts that are resistant to sintering at high temperatures are provided. The catalysts include a metal nanoparticle bound to a metal oxide support, where the metal nanoparticle and support are coated with a porous metal oxide coating layer. The catalyst is prepared by contacting a metal nanoparticle bound to a metal oxide support with a solution of metal salts, drying the solution of metal salts, and calcining the metal salts to generate a porous metal oxide coating on the metal nanoparticle and metal oxide support.

Description

technical field [0001] The present disclosure relates to catalysts resistant to sintering at high temperatures and low cost methods for preparing catalysts resistant to sintering at high temperatures. Background technique [0002] This section provides background information related to the present invention which is not necessarily prior art. [0003] Metal nanoparticles can form an integral part of the active sites of catalysts used in various applications such as for the production of fuels, chemicals and pharmaceuticals, and for emission control from automobiles, factories and power plants. Metal nanoparticles are often coupled to support materials due to their tendency to aggregate, which reduces their surface area and reduces the accessibility of active sites. The support physically separates the metal nanoparticles to prevent their aggregation and serves to increase their surface area and enhance the accessibility of the active sites. Thus, a catalyst system typicall...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J33/00B01J23/40

CPCB01J23/40B01J33/00B01J37/0215B01J37/0221B01J37/08

Inventor R·J·戴X·肖G·齐

Owner GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com