A kind of multi-layer multifunctional thermal insulation material and preparation method thereof

A thermal insulation, multi-functional technology, applied in chemical instruments and methods, layered products, other household appliances, etc., can solve problems such as non-compliance and affecting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

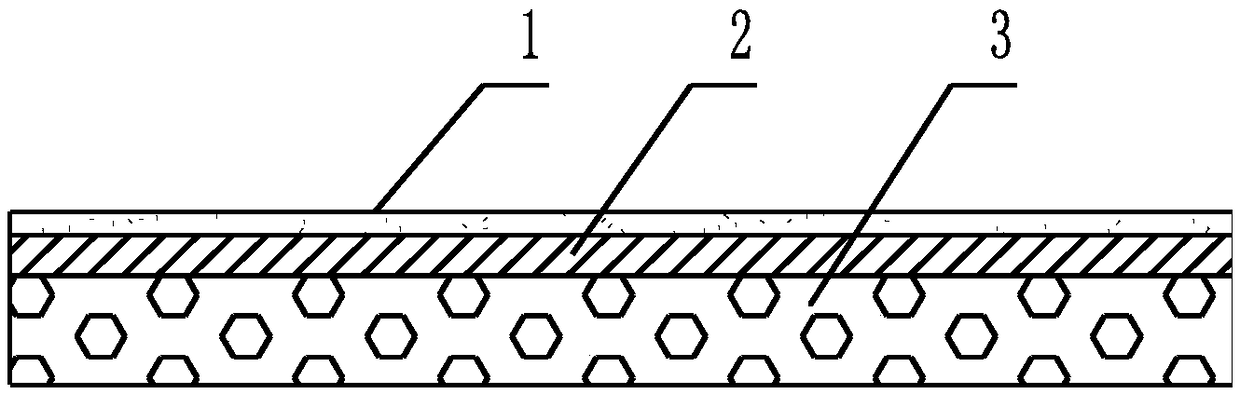

[0091] Example 1: A multi-layer multi-functional thermal insulation material and its preparation method, which has two shapes and structures: flat plate structure or round tubular structure; in this embodiment, the planar plate structure is sequentially arranged from the bottom layer to the surface layer: base layer 3 , transition layer 2 and surface layer 1;

[0092] (1) Preparation of the base layer

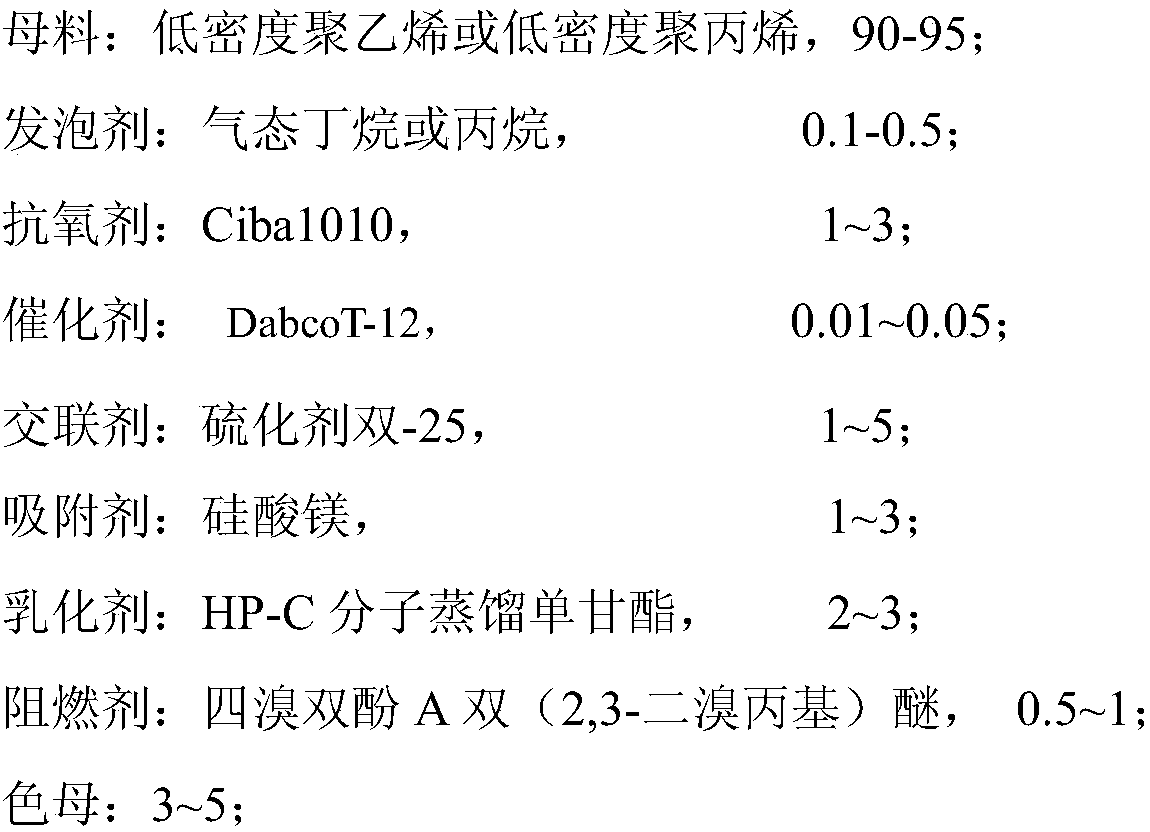

[0093] Described base layer, its composition and weight parts ratio are as follows:

[0094] Use materials with resistance to heat flow as the masterbatch, low-density polyethylene (or low-density polypropylene), 90;

[0095] Foaming agent: butane or propane (gaseous), which can increase the proportion of holes in the masterbatch, 0.1;

[0096] Antioxidant: Ciba1010, which can prevent the oxidation of the masterbatch in the air, 1;

[0097] Catalyst: Dabco (triethylenediamine) T-12, which can accelerate the curing of the masterbatch, 0.01;

[0098] Crosslinking agent: vulca...

Embodiment 2

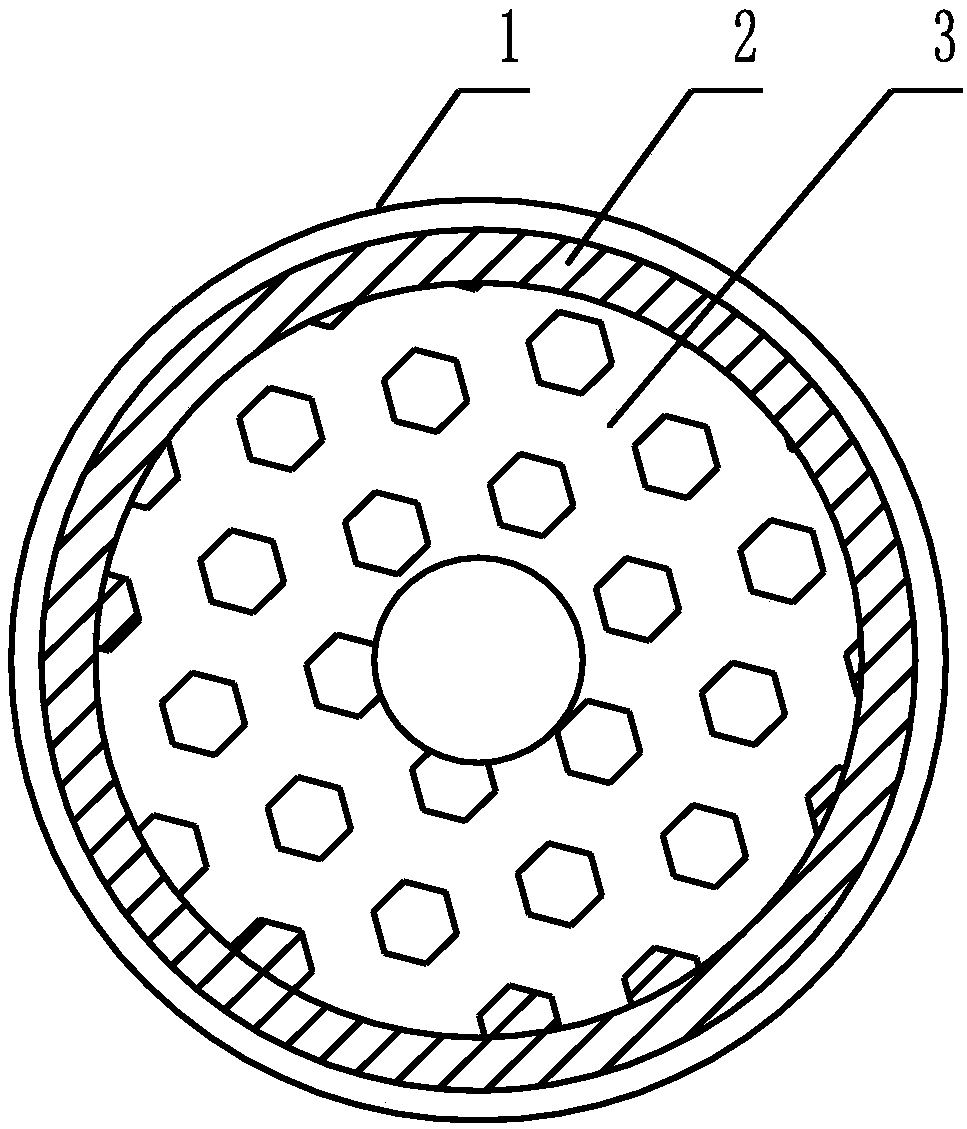

[0147] Embodiment 2: A multi-layer multi-functional thermal insulation material, which has two shapes and structures: a flat plate structure or a circular tubular structure; this embodiment is a tubular structure, which is sequentially arranged from the inner layer to the outer layer: the base layer 3, the transition layer 2 and surface layer 2 4;

[0148] A multi-layer multifunctional thermal insulation material and a preparation method thereof,

[0149] (1) Preparation of the base layer

[0150] Described base layer, its composition and weight parts ratio are as follows:

[0151] Use materials with resistance to heat flow as the masterbatch, low-density polyethylene (or low-density polypropylene), 95;

[0152] Foaming agent: butane or propane (gaseous), which can increase the proportion of holes in the masterbatch, 0.5;

[0153] Antioxidant: Ciba1010, which can prevent the oxidation of the masterbatch in the air, 3;

[0154] Catalyst: Dabco (triethylenediamine) T-12, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com