Six-shaft industrial robot automatic pot loading system for spark plug porcelain blank

A technology of industrial robots and spark plugs, applied in the manufacture of spark plugs, conveyor objects, transportation and packaging, etc., can solve problems such as inseparable from people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, the technical implementation solution of the present invention will be described in conjunction with the drawings and preferred embodiments.

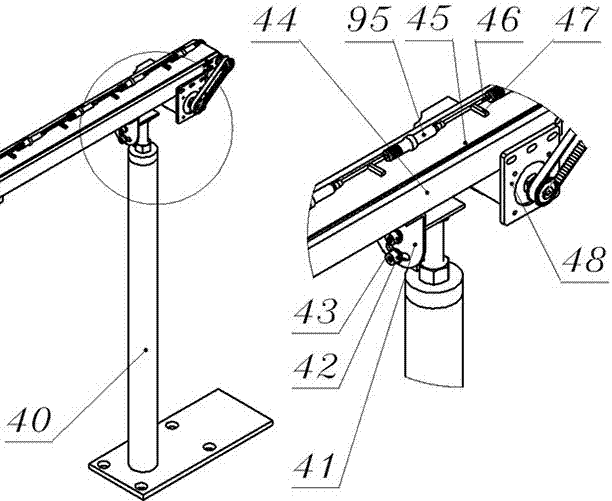

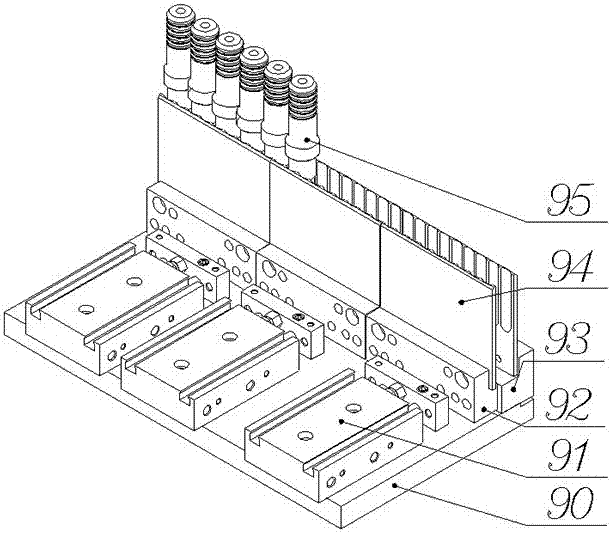

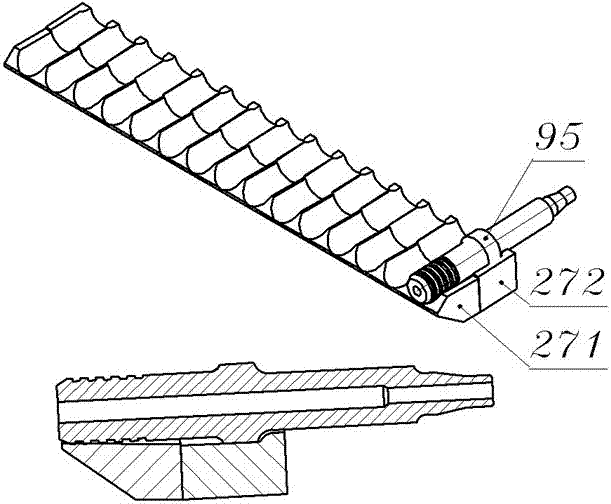

[0020] to combine figure 1 It can be seen that the present invention consists of an installation base plate 1, a robot elevating frame 11, a six-axis industrial robot 10, a discharge machine 2, a waste recycling box 3, a conveyor belt 4, a waste diversion groove 5, a visual inspection camera mounting frame 6, and a visual inspection camera. 7. It consists of a turntable 8 and a robot end fixture group 9.

[0021] to combine figure 2 It can be seen that the turntable 8 includes a working crucible bowl clamping and positioning unit 80 , an electrical control box 81 surrounded by a bracket and an outer shell, and the turntable and six crucible bowls installed on the turntable form a rotary workbench 82 . Wherein the working crucible bowl clamping and positioning unit 80 includes a sliding plate 801 that can slide up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com