Cage type rotor shaft radial mixed magnetic flux multi-disc type permanent magnet motor

A squirrel-cage rotor, permanent magnet motor technology, applied to synchronous motors with stationary armatures and rotating magnets, asynchronous induction motors, and magnetic circuit shapes/styles/structures, etc. Unstable starting process, low starting torque, etc., to achieve the effect of facilitating processing and later operation and maintenance, widening the speed regulation range, and compact motor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0030] The invention provides a permanent magnet motor that can not only improve the space utilization rate of the motor, but also improve the torque quality, torque density and system efficiency, and can take into account both low-speed and high-speed operation performance. The motor can be used for high-end CNC machine tool electric spindles , robot joints, electric vehicle hub drives, etc.

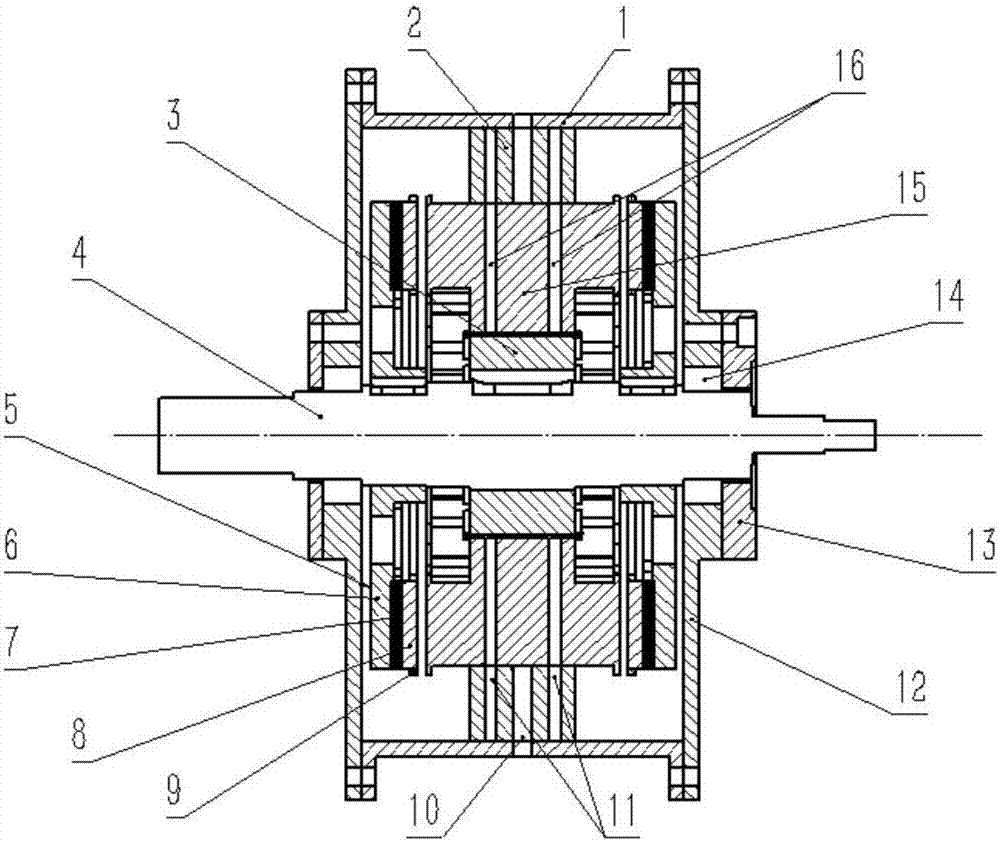

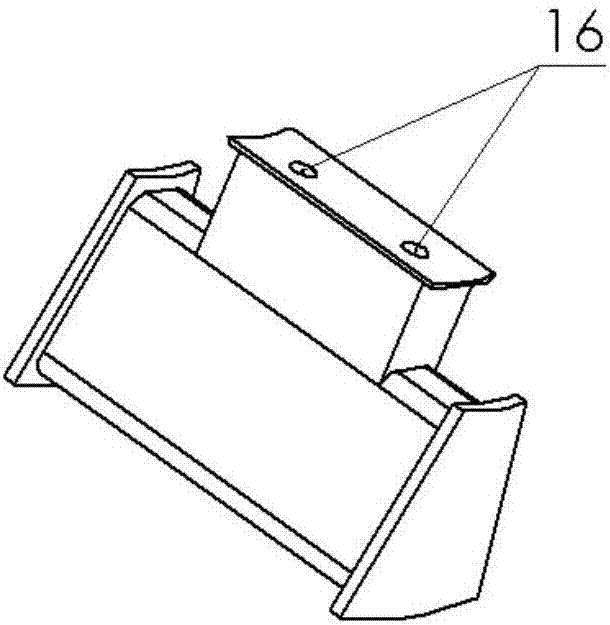

[0031] Such as figure 1 As shown, the present invention provides a cage-type rotor shaft radial mixed flux multi-disk permanent magnet motor, including a stator, a rotor, and a motor casing composed of a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com