Coherent making method of haw beverages, dried haw fruits and haw noodles, and processed products made by coherent making method

A production method and technology of hawthorn, applied in food preservation, confectionary industry, confectionery, etc., can solve the problems of large damage to nutrients and poor taste of processed hawthorn products, so as to achieve sweet and sour taste, improved taste and rich nutrition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

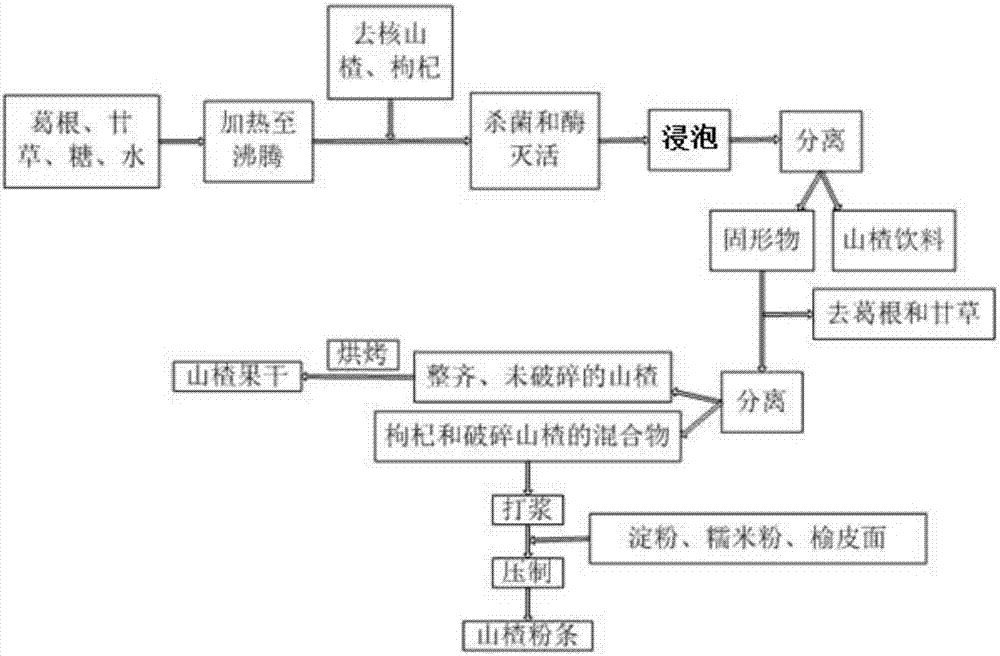

Method used

Image

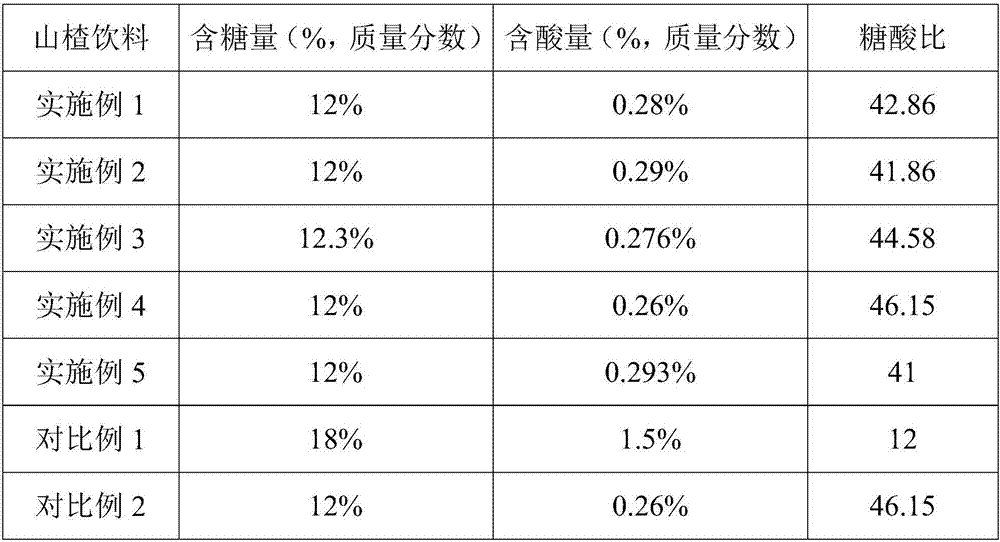

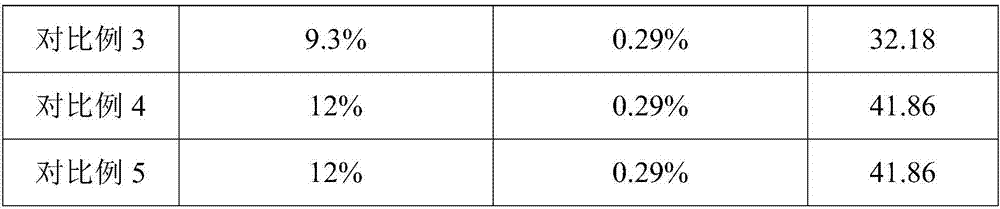

Examples

Embodiment 1

[0041] This embodiment provides a coherent production method of hawthorn beverage, dried fruit and vermicelli. It includes the following steps:

[0042] 1) Soak the frozen hawthorn in water at 0°C. The water covers the surface of the fruit for 10mm, and then freeze it to reduce its contact time with oxides in the air, prevent it from spoilage, and stir once every 8 minutes until the soaking time reaches 15 minutes. , feel the pulp softening by hand; take it out, and then soak it in 1.5wt% salt water for 20 minutes to remove the dirt and bacteria on the surface of the hawthorn; finally, use a pitter to poke out the core to obtain the pulp, that is, the pitted hawthorn;

[0043] 2) Pour 1500g of water into the electric heating stainless steel sandwich pot, then take 12g of kudzu root and 4.5g of licorice, wash them, put them in water, and heat to boiling; then, take 840g of white sugar and put them into boiling water to dissolve; finally, put Rinse 600g of pitted hawthorn and 7...

Embodiment 2

[0050] This embodiment provides a coherent production method of hawthorn beverage, dried fruit and vermicelli. It includes the following steps:

[0051] 1) Soak the frozen hawthorn in water at -2°C. The water covers the surface of the fruit for 10mm, and then freeze it to reduce its contact time with the oxides in the air and prevent it from spoiling. Stir once every 10 minutes until the soaking time reaches For 10 minutes, feel the pulp softened by hand; take it out, and then soak it in 2wt% salt water for 15 minutes to remove the dirt and bacteria on the surface of the hawthorn; finally, use a pitter to poke out the core to obtain the pulp, that is, the pitted hawthorn;

[0052] 2) Pour 1000g of water into an air-heated stainless steel jacketed pot, then take 6g of kudzu root and 4g of licorice, wash them, put them in water, and heat to boiling; then, take 400g of white sugar and dissolve in boiling water; finally, put Rinse 500g of pitted hawthorn and 4g of wolfberry with ...

Embodiment 3

[0059] This embodiment provides a coherent production method of hawthorn beverage, dried fruit and vermicelli. It includes the following steps:

[0060] 1) Soak the frozen hawthorn in water at 2°C. The water covers the surface of the fruit by 10mm, and then freeze it to reduce its contact time with oxides in the air, prevent it from spoilage, and stir once every 5 minutes until the soaking time reaches 20 minutes. , feel the pulp softened by hand; take it out, and then soak it in 1wt% salt water for 30 minutes to remove the dirt and bacteria on the surface of the hawthorn; finally, use a pitter to poke out the core to obtain the pulp, that is, the pitted hawthorn;

[0061] 2) Pour 1000g of water into an electric heating stainless steel jacketed pot, then take 10g of kudzu root and 2g of licorice, wash them, put them in water, and heat them to boiling; then, take 600g of white sugar and dissolve them in boiling water; finally, put 300g of The pitted hawthorn and 6g wolfberry w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com