Graphene/silica composite aerogel material and preparation method thereof

A composite airgel and silicon dioxide technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as poor temperature resistance and easy failure, and achieve the effect of improving high temperature failure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

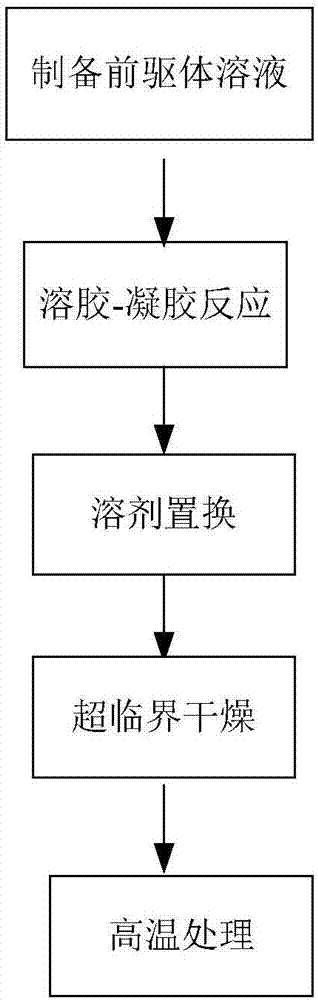

[0020] As mentioned above, the first aspect of the present invention provides a kind of preparation method of graphene / silicon dioxide composite airgel material, described method comprises the steps:

[0021] (1) Preparation of graphene oxide / silica system hydrogel

[0022] Mixing and stirring the silicon dioxide precursor solution and the graphene oxide solution evenly to form a composite precursor solution, and heating the composite precursor solution to obtain a graphene oxide / silica system hydrogel;

[0023] (2) Preparation of graphene oxide / silica system alcohol gel

[0024] placing the graphene oxide / silicon dioxide system hydrogel in an alcohol solvent replacement solution for solvent replacement to obtain an alcohol gel;

[0025] (3) Preparation of graphene oxide / silica composite airgel

[0026] The alcohol gel is dried to obtain a graphene oxide / silicon dioxide composite airgel;

[0027] (4) Preparation of graphene / silica composite airgel

[0028] The graphene oxi...

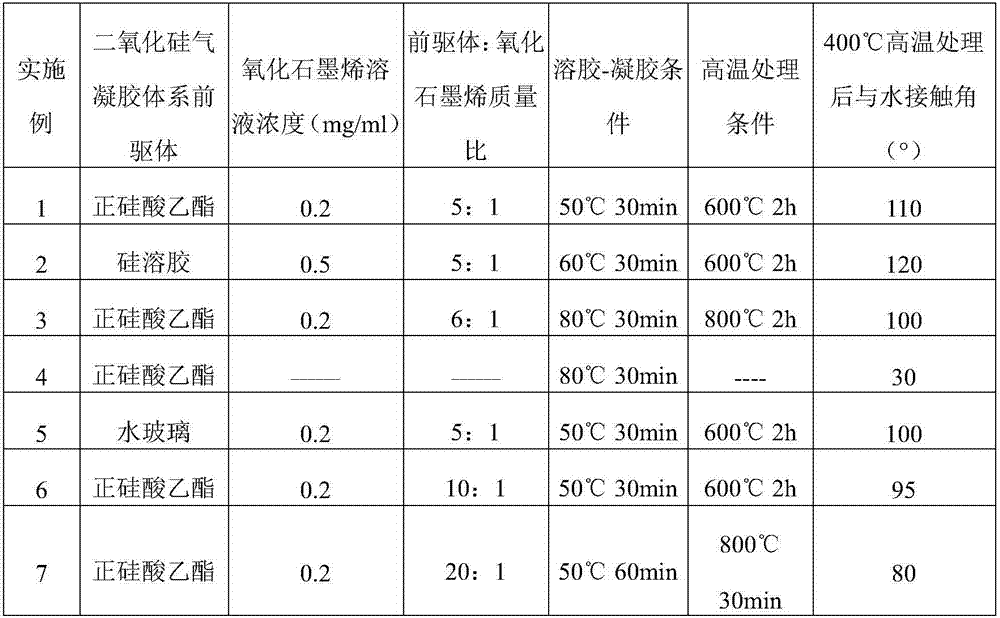

Embodiment 1

[0048] Use tetraethyl orthosilicate precursor solution and 0.2mg / ml graphene oxide solution to mix according to 5:1. After stirring evenly, a composite precursor solution is formed. Put the composite precursor solution in a water bath and heat at 50°C for 30min to obtain Graphene oxide / silica system hydrogel. The hydrogel was placed in an ethanol solution for solvent replacement, and the ethanol was replaced once a day for a total of 3 replacements to obtain a graphene oxide / silica system alcohol gel. The graphene oxide / silica system alcohol gel was taken out and dried by supercritical carbon dioxide (40°C, 10MPa) to prepare the graphene oxide / silica composite aerogel. Finally, after high temperature treatment, the graphene / silicon dioxide composite airgel is prepared. Wherein, the high temperature treatment condition is 600° C., inert atmosphere nitrogen protection, and treatment for 2 hours.

Embodiment 2

[0050] Use silica sol solution and 0.5mg / ml graphene oxide solution to mix according to 5:1, after stirring evenly, form a composite precursor solution, put the composite precursor solution in a water bath and heat at 60°C for 30min to obtain graphene oxide / dioxide Silica system hydrogel. The hydrogel was placed in an ethanol solution for solvent replacement, and the ethanol was replaced once a day for a total of 3 replacements to obtain a graphene oxide / silica system alcohol gel. The graphene oxide / silica system alcohol gel was taken out, and subjected to supercritical drying (40° C., 10 MPa), to prepare a graphene oxide / silica composite airgel. Finally, after high temperature treatment, the graphene / silicon dioxide composite airgel is prepared. Wherein, the high temperature treatment condition is 600° C., inert atmosphere nitrogen protection, and treatment for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com