Preparation method of polydimethylsiloxane (PDMS) modified polyurethane-imides (PUI) hybrid material

A polydimethylsiloxane and hybrid material technology, applied in the direction of coating, etc., can solve the problems of low mechanical strength, easy to be corroded, unable to withstand high intensity of ultraviolet rays and long-term irradiation, etc., and achieve a simple and easy preparation process. easy to industrialize, easy to apply on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

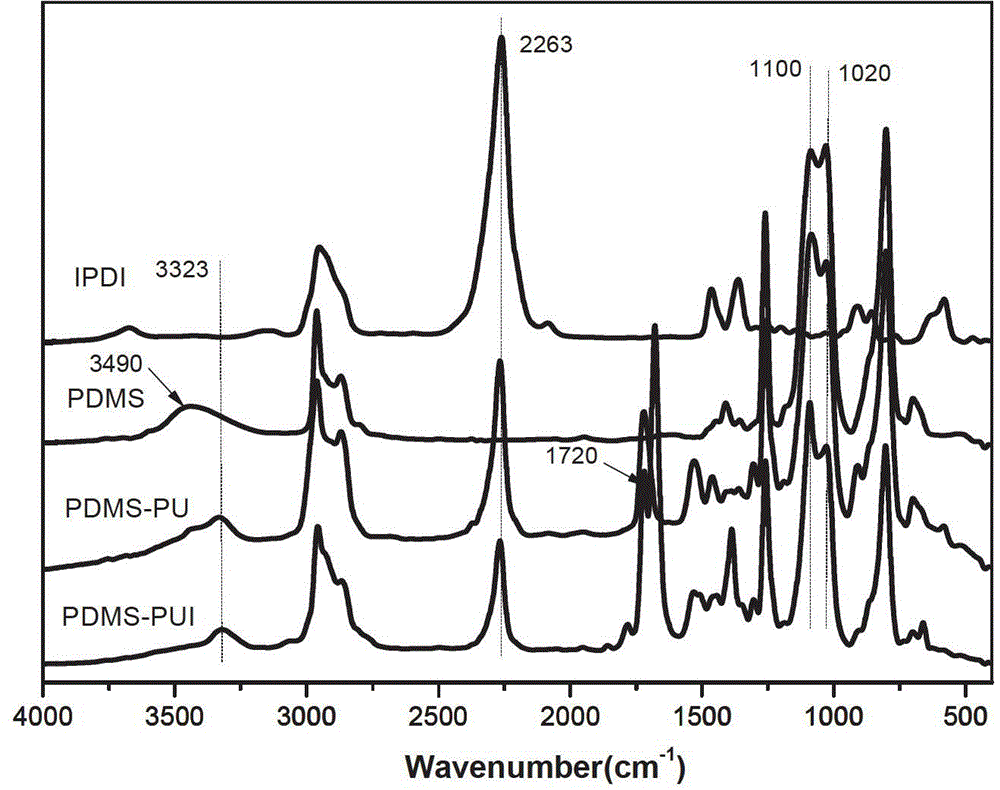

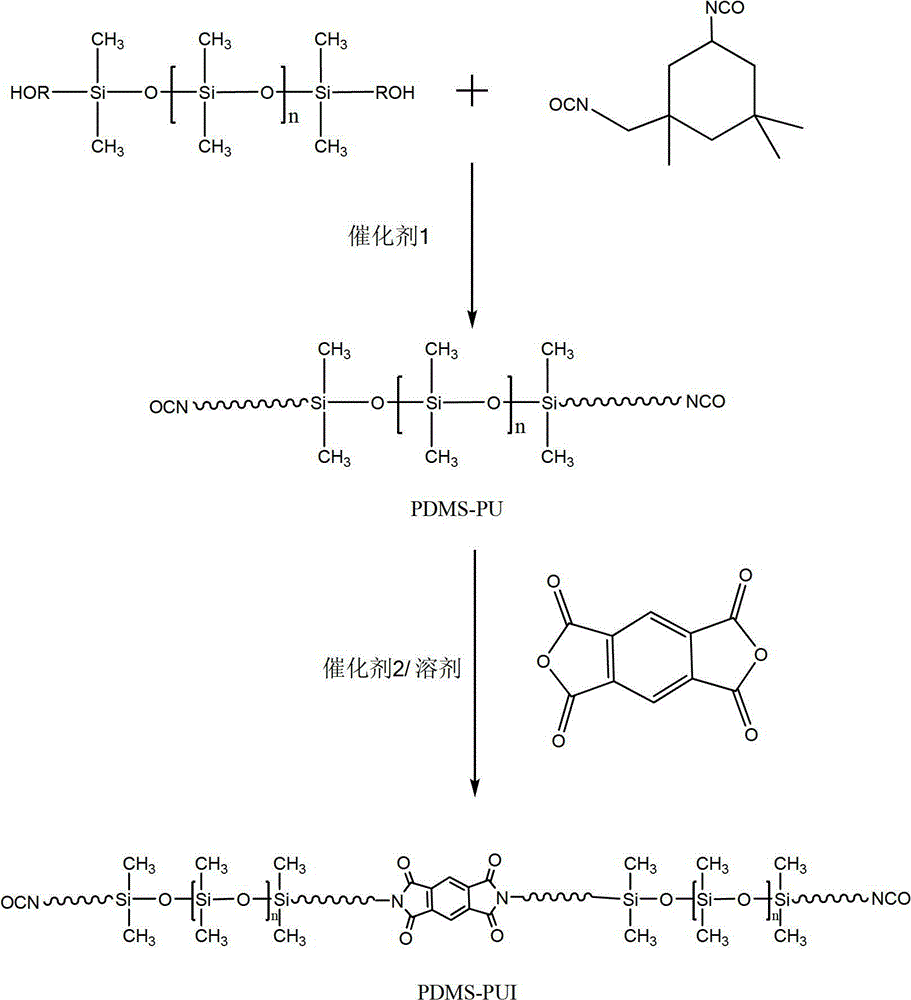

[0021] (1) Synthesis of polydimethylsiloxane-modified poly(urethane-imide) PDMS-PUI prepolymer. Add 25.5g of isophorone diisocyanate into a 250ml three-necked flask and stir, protect with nitrogen, drop 0.2g of the toluene solution (wt=20%) of the catalyst dibutyltin dilaurate, and raise the temperature to 50°C for the catalyst dilaurate Dibutyltin was activated for 20 minutes; then 53.64g of dehydrated hydroxyalkyl-terminated polydimethylsiloxane was added dropwise to the system, and after reacting at 70°C for 4 hours, a small amount was taken out to measure the infrared spectrum. The disappearance of the hydroxyl group indicated that the reaction was complete. Its infrared absorption characterization data is attached figure 1 Shown: FTIR (cm-1, KBr) 2263 (v-NCO), 3323 (vN-H), 3490 (-OH), 1100, 1020 (Si-O-Si).

[0022] (2) Lower the temperature of the above system to 60°C, add 6.26g of pyromellitic anhydride to the system, then add 75ml of N,N'-dimethylformamide dropwise to ...

example 2

[0028] (1) Synthesis of polydimethylsiloxane-modified poly(urethane-imide) PDMS-PUI prepolymer. Add 25.5g of isophorone diisocyanate into a 250ml three-necked flask and stir, protect with nitrogen, drop 0.3g of the toluene solution (wt=20%) of the catalyst dibutyltin dilaurate, and raise the temperature to 50°C for the catalyst dilaurate Dibutyltin was activated for 20 minutes; then 53.64g of dehydrated hydroxyalkyl-terminated polydimethylsiloxane was added dropwise to the system, reacted at 70°C for 4 hours, and a small amount was taken out for infrared spectroscopy. The disappearance of hydroxyl groups indicated that the reaction was complete. Its infrared absorption characterization data is attached figure 1 Shown: FTIR (cm-1, KBr) 2263 (v-NCO), 3323 (vN-H), 3490 (-OH), 1100, 1020 (Si-O-Si).

[0029] (2) Cool the above system to 50°C, add 6.26g of pyromellitic anhydride to the system, then add 75ml of N,N'-dimethylformamide dropwise to the system, and add 0.3g of catalyst ...

example 3

[0035] (1) Synthesis of polydimethylsiloxane-modified poly(urethane-imide) PDMS-PUI prepolymer. Add 25.5g of isophorone diisocyanate into a 250ml three-necked flask and stir, protect with nitrogen, drop 0.3g of the toluene solution (wt=20%) of the catalyst dibutyltin dilaurate, and raise the temperature to 50°C for the catalyst dilaurate Dibutyltin was activated for 20 minutes; then 53.64g of polydimethylsiloxane capped with dehydrated hydroxyalkyl groups was added dropwise to the system, and after reacting at 70°C for 4 hours, a small amount was taken out to measure the infrared spectrum. The disappearance of the hydroxyl group indicated that the reaction was complete. Its infrared absorption characterization data is attached figure 1 Shown: FTIR (cm-1, KBr) 2263 (v-NCO), 3323 (vN-H), 3490 (-OH), 1100, 1020 (Si-O-Si).

[0036] (2) Cool the above system to 40°C, add 6.26g of pyromellitic anhydride to the system, then add 75ml of N,N'-dimethylformamide dropwise to the system, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com