A kind of preparation method of high-purity natural garlic ajoene

An ajoene and high-purity technology, applied in the field of preparation of high-concentration natural garlic ajoene, can solve the problems of difficulty in breaking through bottlenecks, high cost, and large amount of preparation raw materials in the purity improvement technology, so as to reduce the amount of consumption, save raw materials, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Take 10Kg of garlic from Shandong, peel it, pulverize to a particle size of 2mm, add 2Kg of 80% ethanol, stir evenly, and let stand for 2 days to ferment.

[0031] 2. Add 25Kg of 85% ethanol to the above fermentation product, ultrasonically extract for 1 hour, and filter. The filtrate is concentrated under reduced pressure at a temperature of 55-75°C to remove the ethanol in the filtrate to obtain an ultrasonic extract.

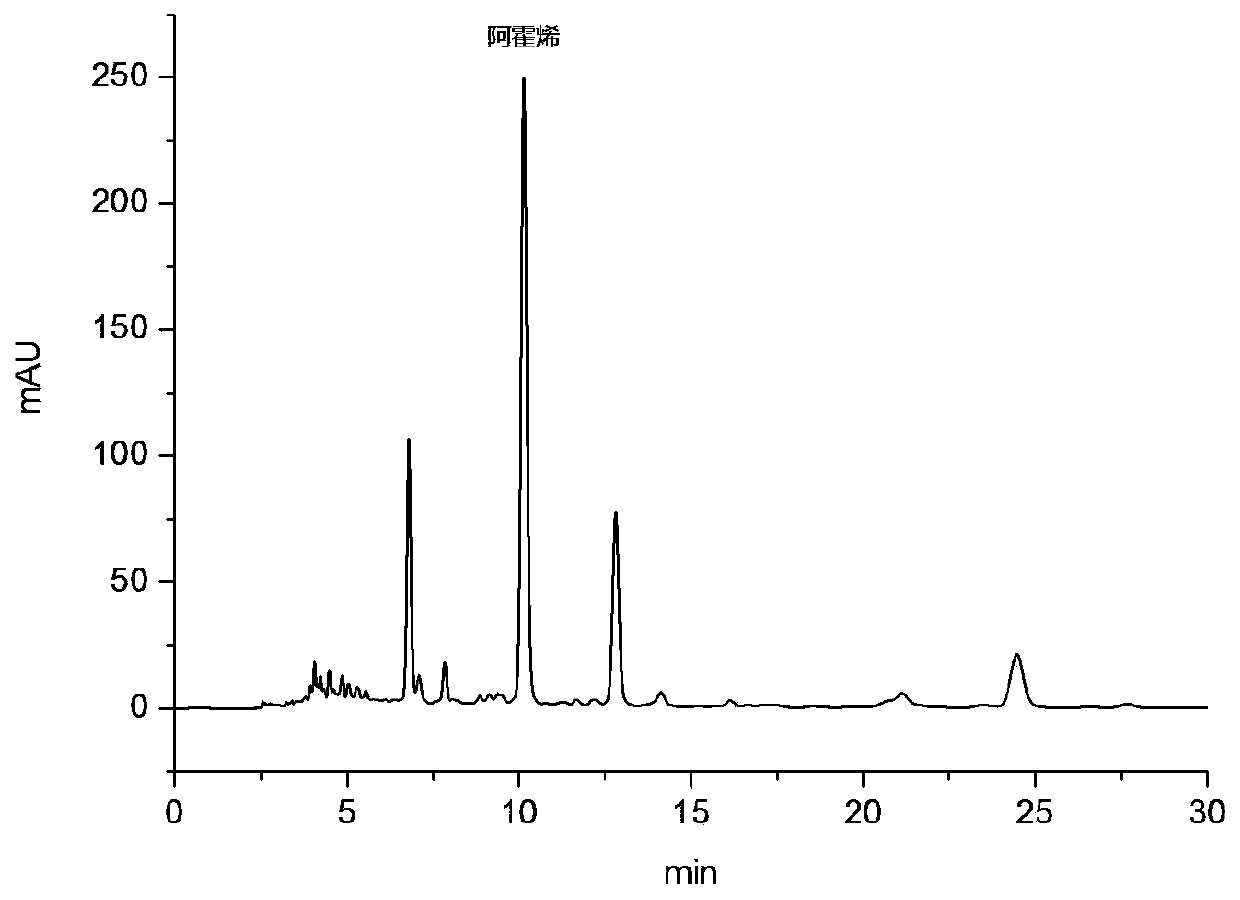

[0032] 3. Put the above ultrasonic extract in supercritical CO 2 In the extraction kettle of the extraction device, the extraction pressure is adjusted to 20Mpa, the extraction temperature is 50°C, the separation kettle I pressure is 15Mpa, and the separation kettle I temperature is 60°C. When the extraction and separation conditions reach the set requirements, the cyclic extraction is started for 1.5 hours, and samples are collected from the separation tank II. Such as figure 1 Shown is supercritical CO 2 High performance liquid chromatogram of the extr...

Embodiment 2

[0037] 1. Take 10Kg of garlic from Jilin, peel it, pulverize it to a particle size of 10mm, add 0.5Kg of 95% ethanol, stir evenly, and let stand for 2 days for fermentation.

[0038] 2. Add 40Kg of 60% ethanol to the above fermented product each time, ultrasonically extract 3 times, 2h each time, and filter. The filtrate is concentrated under reduced pressure at a temperature of 55-75°C to remove the ethanol in the filtrate to obtain an ultrasonic extract.

[0039] 3. Put the above ultrasonic extract in supercritical CO 2 In the extraction kettle of the extraction device, the extraction pressure is adjusted to 30Mpa, the extraction temperature is 40°C, the separation kettle I pressure is 18Mpa, and the separation kettle I temperature is 70°C. When the extraction and separation conditions reach the set requirements, the cyclic extraction is started for 2.5 hours, and samples are collected from the separation tank II.

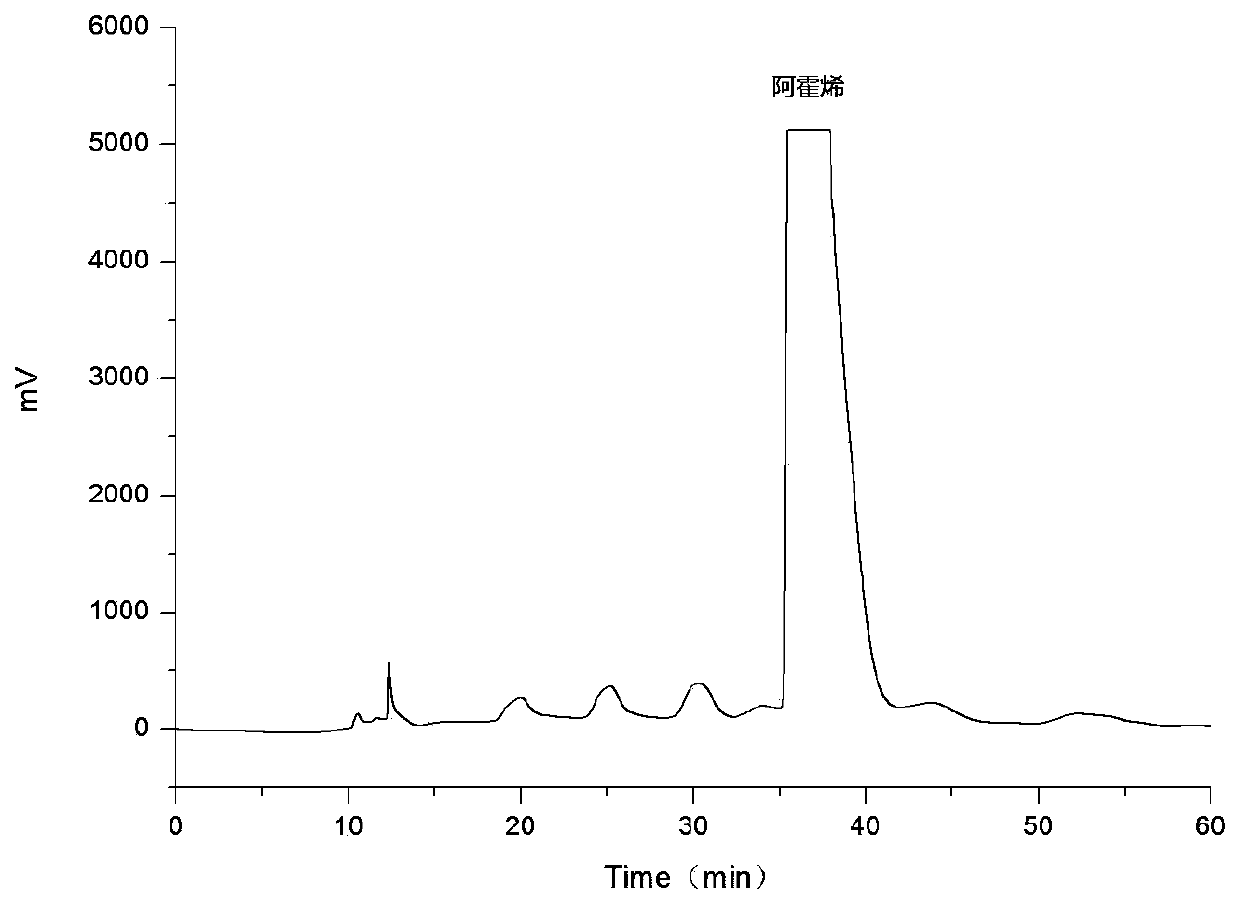

[0040] 4. The supercritical CO 2 The extracted and purified sample...

Embodiment 3

[0044] 1. Take 10Kg of garlic from Ningxia, peel it, pulverize it to a particle size of 0.5mm, add 3Kg of 60% ethanol, stir evenly, and let stand for 2 days for fermentation.

[0045] 2. Add 10Kg of 95% ethanol to the above fermentation product each time, ultrasonically extract twice, 0.5h each time, filter, and concentrate the filtrate under reduced pressure at a temperature of 55-75°C to remove the ethanol in the filtrate to obtain an ultrasonic extract.

[0046] 3. Put the above ultrasonic extract in supercritical CO 2 In the extraction kettle of the extraction device, the extraction pressure is adjusted to 15Mpa, the extraction temperature is 70°C, the separation kettle I pressure is 9Mpa, and the separation kettle I temperature is 45°C. When the extraction and separation conditions reach the set requirements, the cyclic extraction is started for 0.5h, and samples are collected from the separation tank II.

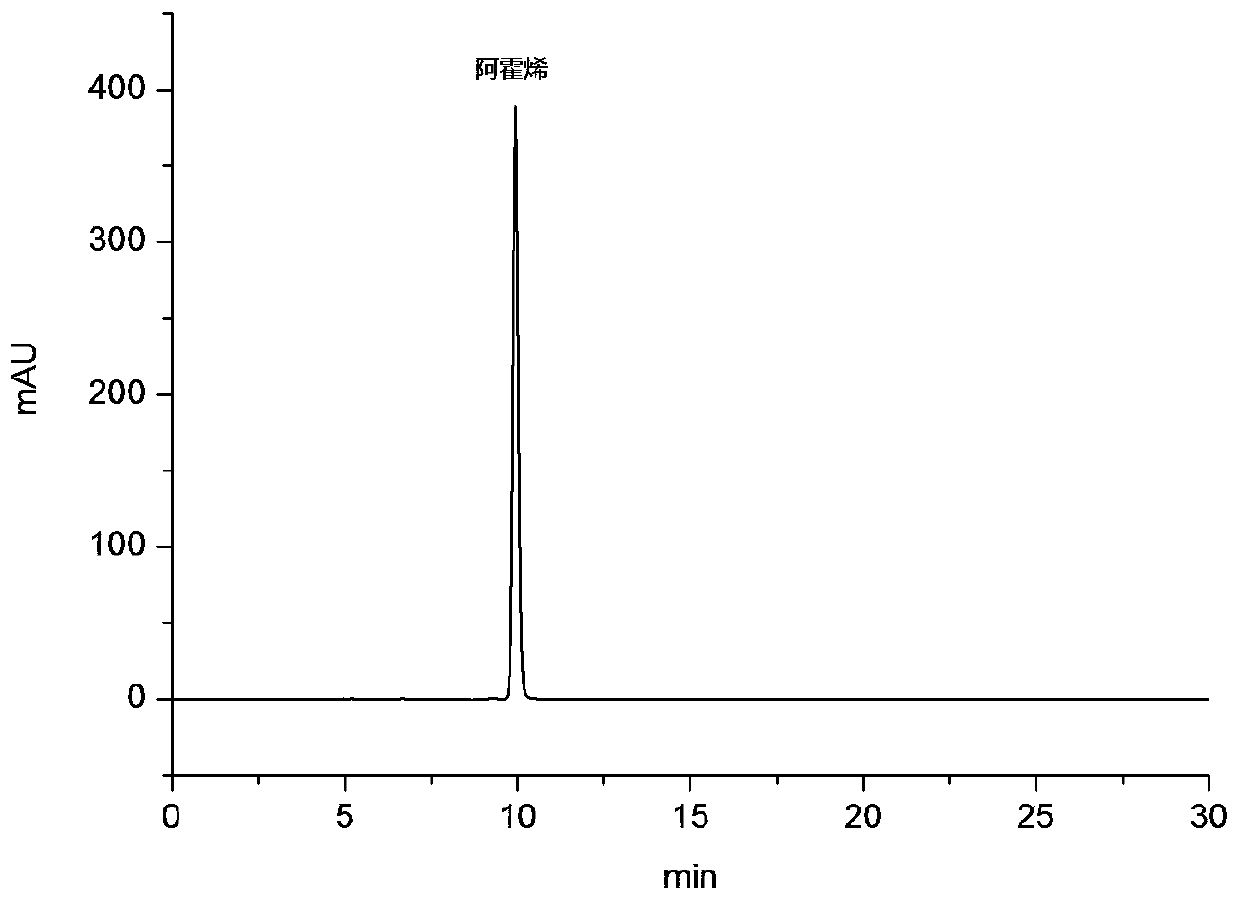

[0047] 4. The supercritical CO 2 The extracted and purified sample is di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com