Preparation method of water-based aliphatic polyurethane adhesive for electronic process protection

An aliphatic polyurethane and adhesive technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of solvent-based coatings such as VOC environmental protection, PVC refractory degradation, etc., to achieve no easy Flammable and explosive, reasonable solid content, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of One-component Waterborne Polyurethane Protective Adhesive

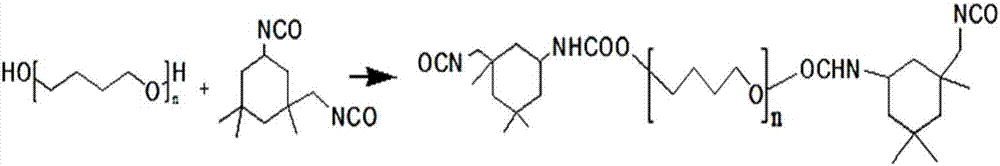

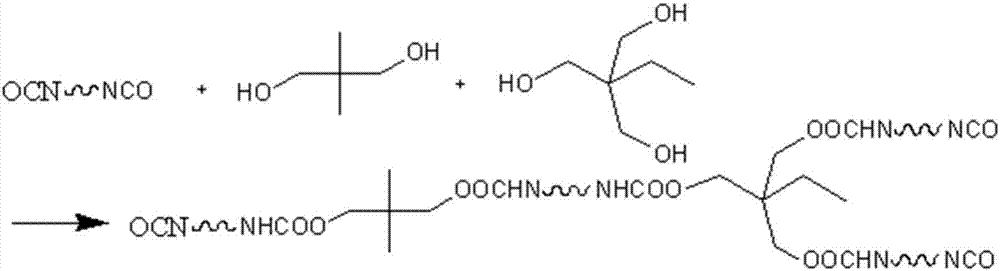

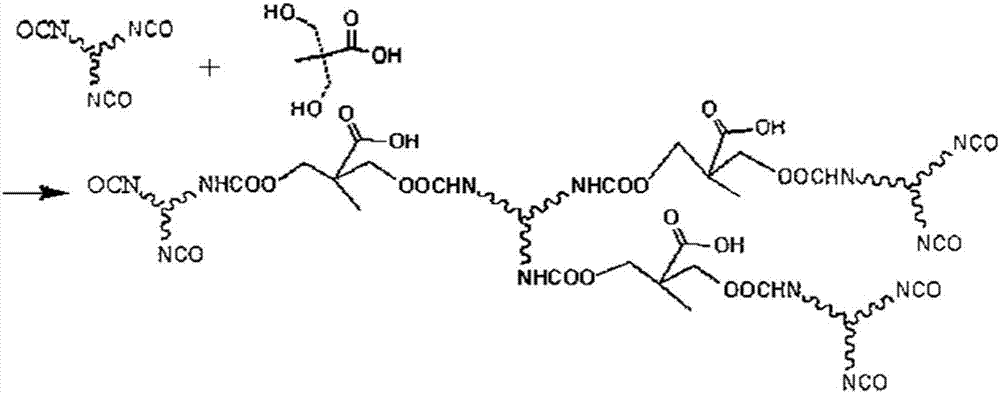

[0041] (1) Preparation of aliphatic water-based polyurethane: put 120g of PTMEG1000 (functionality 2, molecular weight 1000) into a 1L three-necked flask equipped with a reflux condenser, a thermometer socket and a feed port, then place it in an oil bath at 120°C, and pump Vacuum for 1h. Then cool down to 75°C, add 109.5g IPDI, heat up to 90°C, start the reaction, the reaction is as follows figure 1 . Keep the temperature at 89±1°C for two hours, then lower the temperature to 70°C, add 3.3g NPG (neopentyl glycol) and 4.5g TMP (trimethylolpropane). After complete melting, add 0.02g dibutyltin dilaurate, then raise the temperature to 78±1°C for 45 minutes, then add 11.85g DMPA (dimethylol propionic acid), DMPA reacts with IPDI as follows: figure 2 , DMPA reacts with the prepolymer as image 3 , Add 60g ACE (the amount of acetone added and the time of adding depends on the viscosity) to reduce ...

Embodiment 2

[0046] Preparation of Two-component Waterborne Polyurethane Protective Adhesive

[0047] The preparation of aliphatic water-based polyurethane is the same as in Example 1. Accurately weigh 500g of polyurethane dispersion, slowly add 1.5g of aziridine crosslinking agent at a speed of 700rmp, then add 1.5-2.5g of leveling agent, 1.0-3.0 g associative thickener (according to screen printing mesh number and required viscosity), 0.5-1.0g defoamer, appropriate amount of wetting agent. Disperse for 20 minutes, filter and discharge.

[0048] The two-component water-based polyurethane protective adhesive is used for acid-free special occasions, and aziridine can be used to block the carboxyl group and improve the strength, such as for ITO or special inks with conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com