Assembly structure and assembly joint of steel pipe concrete combined truss

A technology of steel tube concrete and composite truss, which is applied in truss structures, truss beams, building structures, etc. It can solve the problems of low bearing capacity, small truss shear stiffness, failure of the whole truss, etc., and improve fire performance and durability , improve local stability and stiffness, and reduce the difficulty of transportation and loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

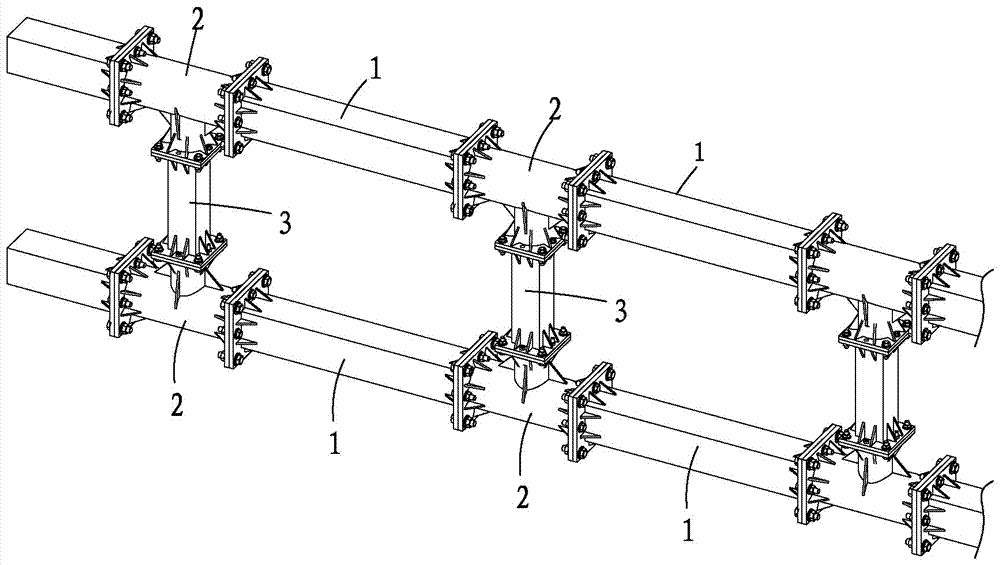

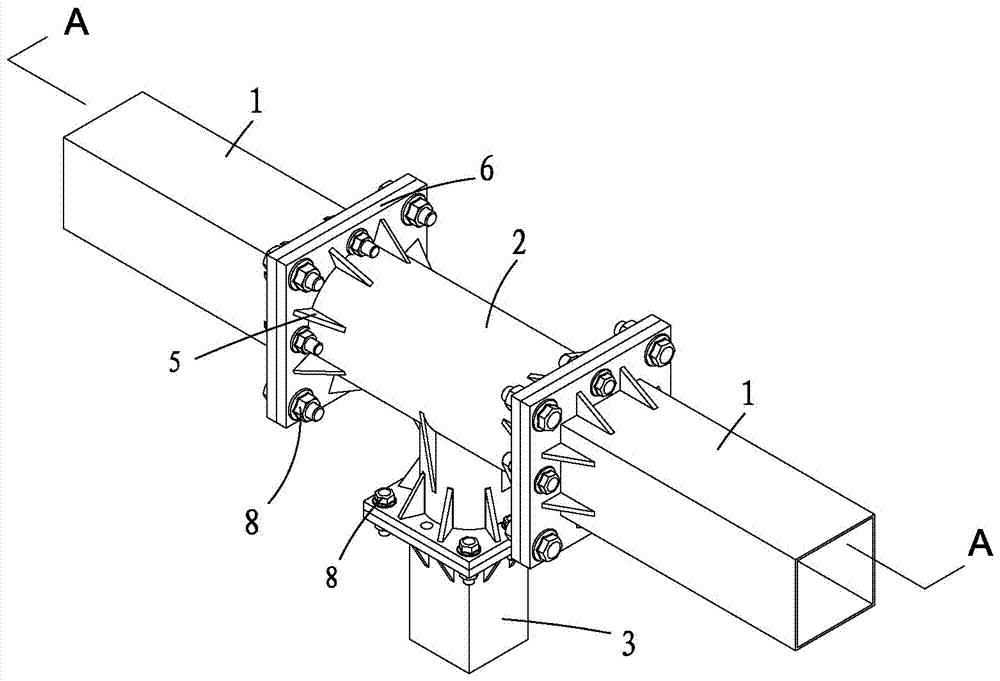

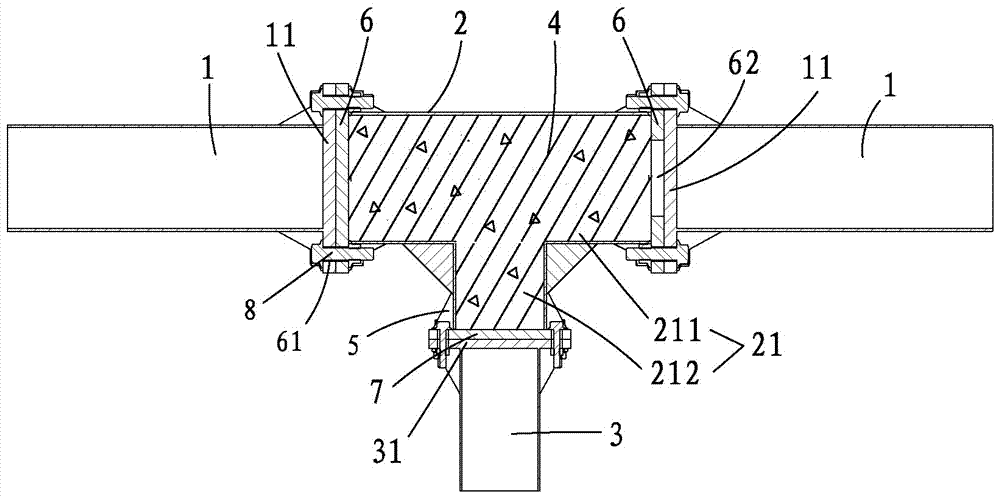

[0030] Such as Figure 1 to Figure 4 As shown, the assembly structure of a steel tube concrete composite truss of the present invention includes at least one main leg steel tube 1, at least one steel tube concrete node 2, and at least one pipe attachment 3, and the steel tube concrete node 2 includes a steel tube node 21, so Described steel pipe node 21 is made up of a chord 211, at least one web 212, and described chord 211 and web 212 are all filled with concrete 4 (such as image 3 As shown), a nozzle of each web 212 is welded on the wall of the chord 211 and communicated with each other, a plurality of stiffeners 5 are welded between the web 212 and the chord 211, the Stiffeners 5 improve the stress conditions at the joints of each component, significantly improve the local stability and stiffness of the joints, increase the bearing capacity and ductility, and effectively avoid buckling at the joints; the two nozzles of the chord 211 are welded There is a first connecting...

Embodiment 2

[0037] see Figure 3 to Figure 4 As shown, the assembly node of a composite steel pipe concrete truss of the present invention, the assembly node includes a steel pipe concrete node 2, and the steel pipe concrete node 2 includes a steel pipe node 21, and the steel pipe node 21 is composed of a chord 211, at least one web Rods 212, the chords 211 and the webs 212 are filled with concrete 4 (such as image 3 As shown), a nozzle of each web 212 is welded on the wall of the chord 211 and communicated with each other, and a plurality of stiffeners 5 are welded between the web 212 and the chord 211, obviously The local stability and rigidity of the connection are improved, the bearing capacity and ductility are improved, and the buckling of the connection is effectively avoided; the two nozzles of the chord 211 are welded with a first connecting plate 6, and the first connecting plate 6 A plurality of stiffeners 5 are welded between the top and the chord 211, a plurality of bolt ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com