Gas turbine combustion chamber

A gas turbine and combustion chamber technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of tempering and self-ignition, insufficiently uniform and sufficient mixing, and high combustion temperature, so as to reduce combustion temperature and improve fuel and air. Premixed structure, the effect of simplifying the combustion chamber structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to improve the air intake mode of the combustion chamber, make the air and high-temperature flue gas mix more uniformly, thereby improving the uniformity of the outlet airflow temperature of the combustion chamber and the energy utilization rate of the combustion chamber, the embodiment of the present invention provides a gas turbine combustion chamber. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

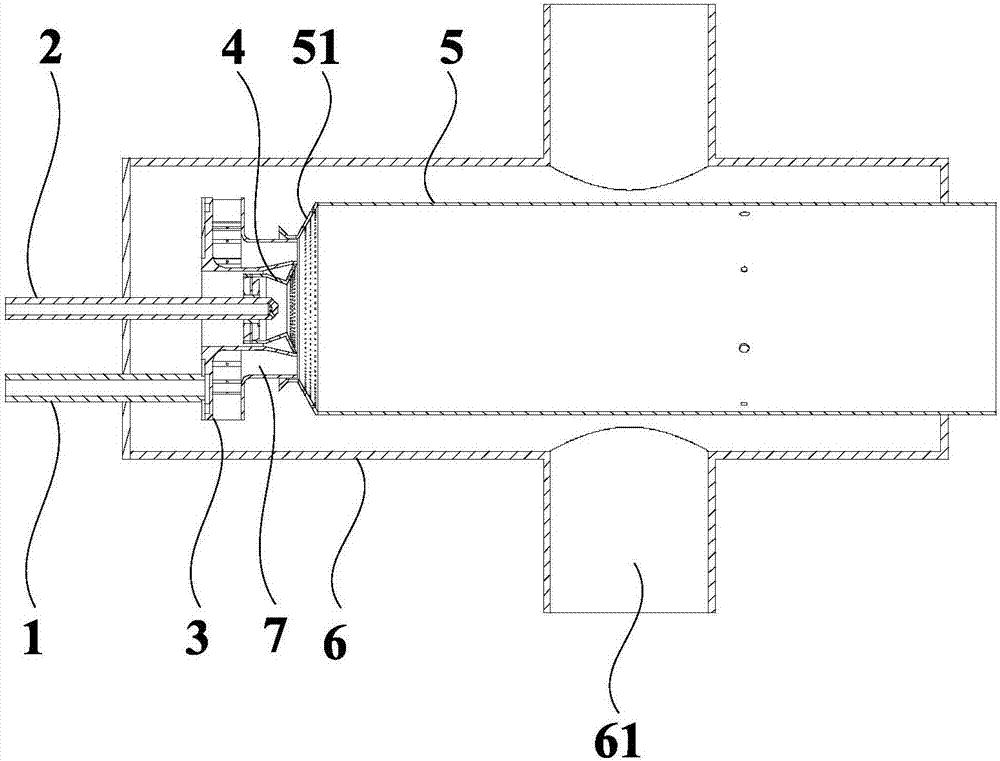

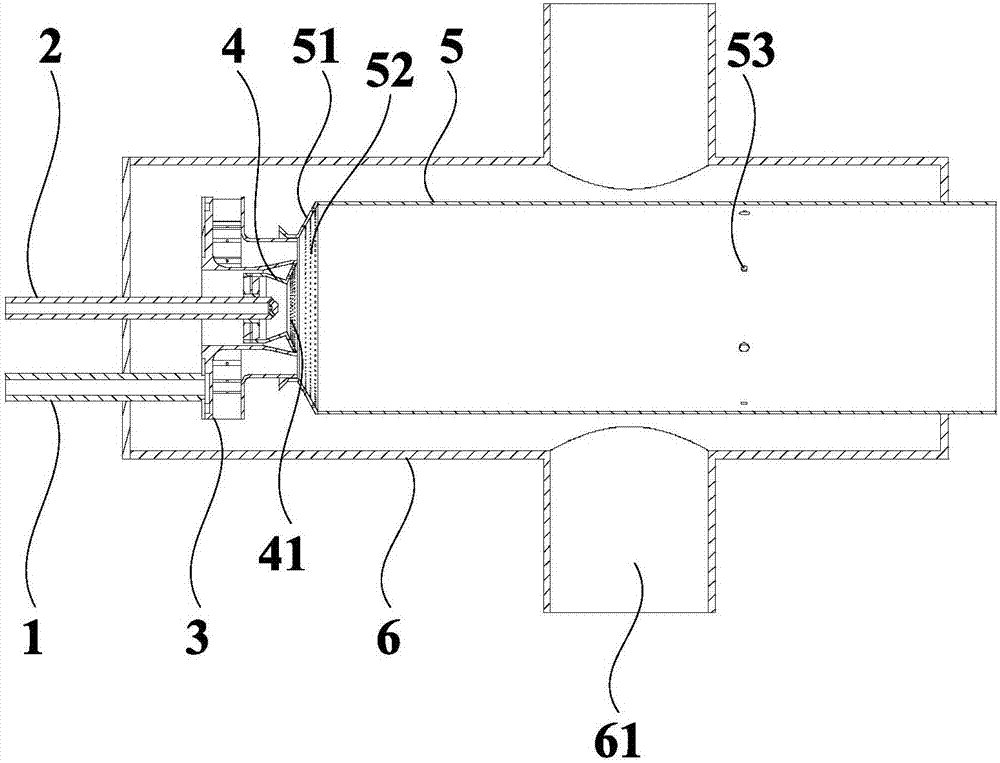

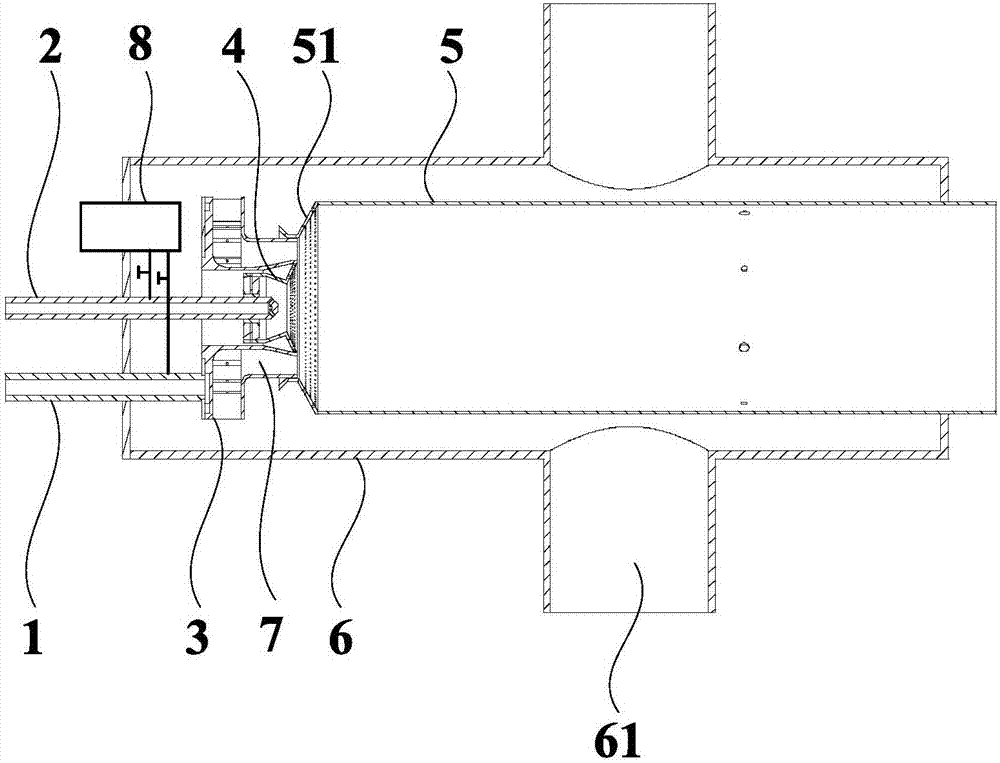

[0034] refer to figure 1 , the combustion chamber provided by an embodiment of the present invention includes a main combustion level fuel pipe 1, a pre-combustion level fuel pipe 2, a main combustion level swirler 3, a pre-combustion level swirler 4, a flame tube 5 and a turbine casing 6. Among them, the discharge port of the main combustion stage fuel pipe 1 communicates with the main combustion stage cyclone 3, the discharge p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com