Brake glide quantity soft measuring method and measuring device

A technology of soft measurement and main control module, applied in measuring devices, devices using electric/magnetic methods, measuring acceleration, etc., can solve problems such as distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

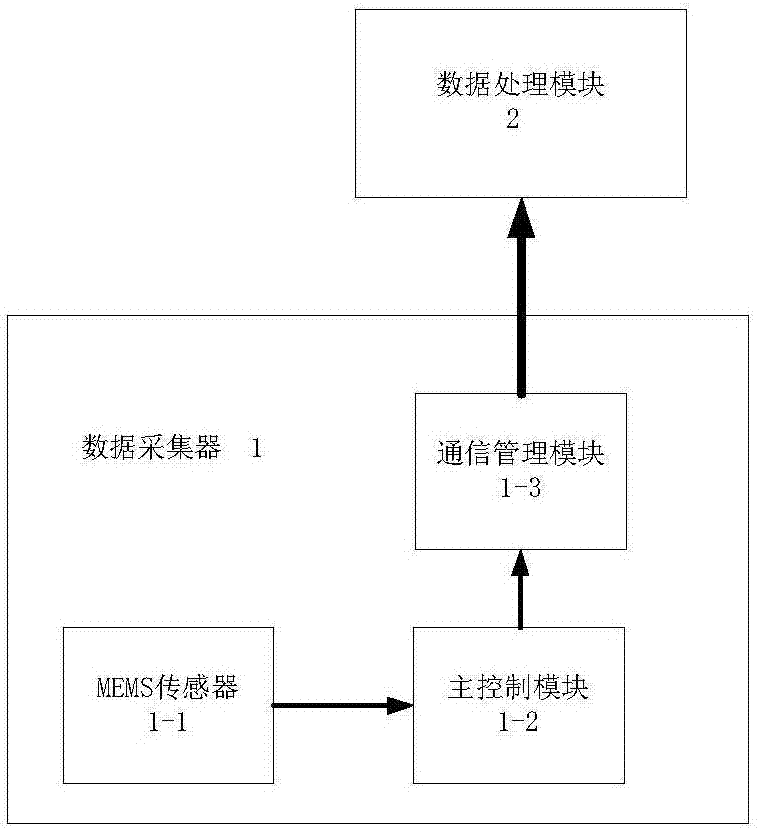

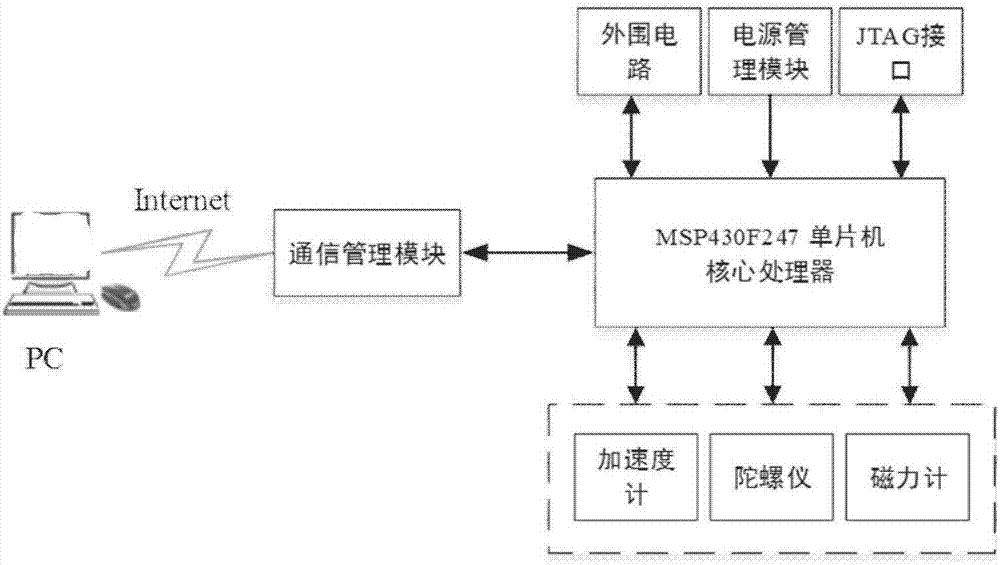

[0049] figure 1 It is an overall block diagram of the measuring device of the present invention. The soft measuring device for the brake sliding amount of the crane in the present invention includes two parts: a data collector 1 and a data processing module 2 . Among them, the data collector is set on the position where the crane hook is in contact with the heavy object. The data collector is composed of MEMS sensors 1-1, main control module 1-2 and communication management module 1-3 connected in series. The communication management module 1- 3 is connected to the data processing module 2 as the output end of the data collector 1 . Among them, the MEMS sensor 1-1 samples the acceleration and angular velocity information of the hoisting system of the crane; the main control module 1-2 is responsible for controlling the MEMS sensor 1-1 and storing the collected acceleration and angular velocity information; the communication management module 1-3 is composed of The main contr...

Embodiment 2

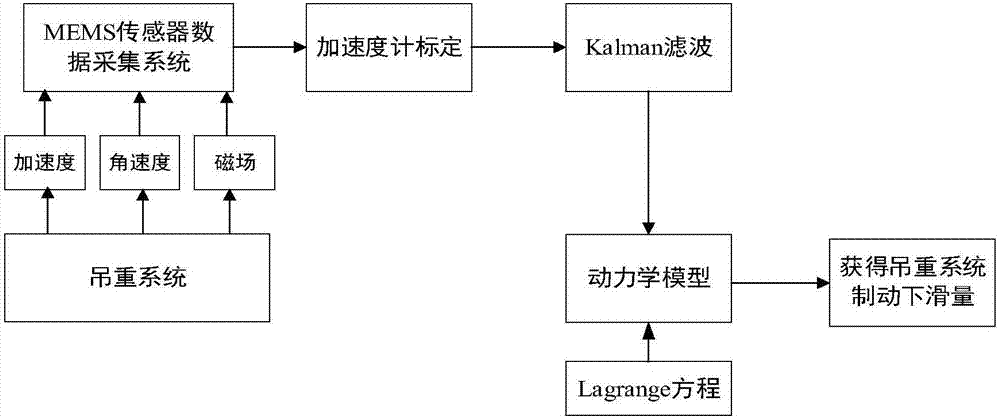

[0086] refer to figure 2 . Further, considering the requirements of measurement accuracy, the present invention improves the above-mentioned measurement method at the same time, and corrects the measurement error of the accelerometer by increasing the calibration of the MEMS sensor (accelerometer calibration). In order to further reduce measurement and calculation errors, Kalman filtering can be performed on the collected information before data processing, so as to keep only valid information and interfere with invalid data. The specific improvements are as follows:

[0087] In the first step of the measurement method described in embodiment 1, the process of calibrating the MEMS sensor is as follows:

[0088] The accelerometer error model on which the calibration is based is as follows:

[0089] A x =B x +S x V x +E xy V y +E xz V z

[0090] A y =B y +E yx V x +S y V y +E yz V z

[0091] A z =B z +E zx V x +E zy V y +S z V z

[0092] In the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com