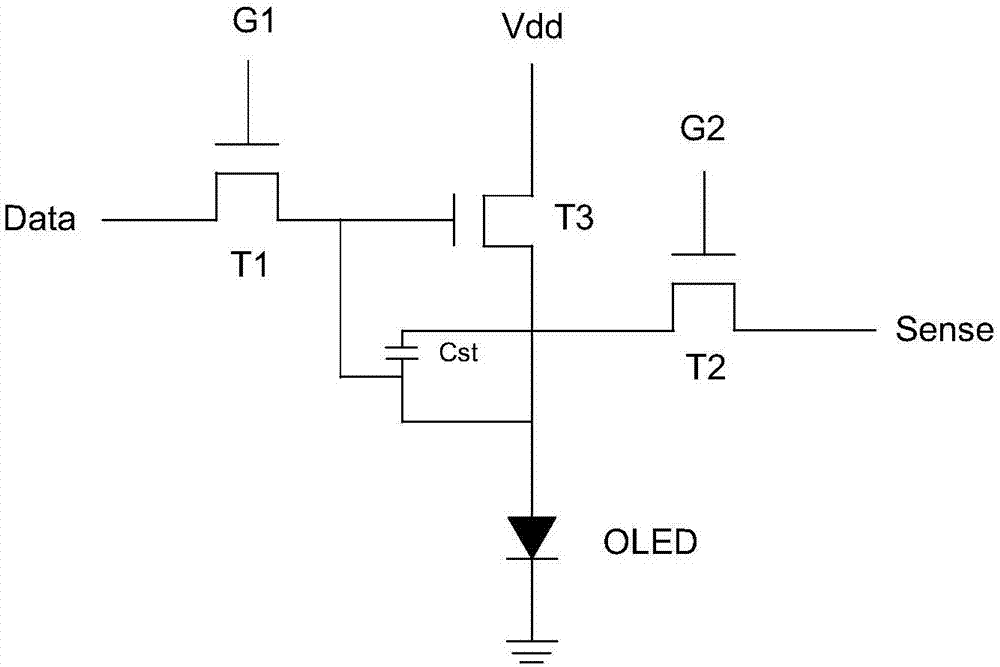

Array substrate and preparation method thereof, display panel and display device

A technology for array substrates and display panels, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as reducing the aperture ratio of display devices and affecting the display quality of display panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

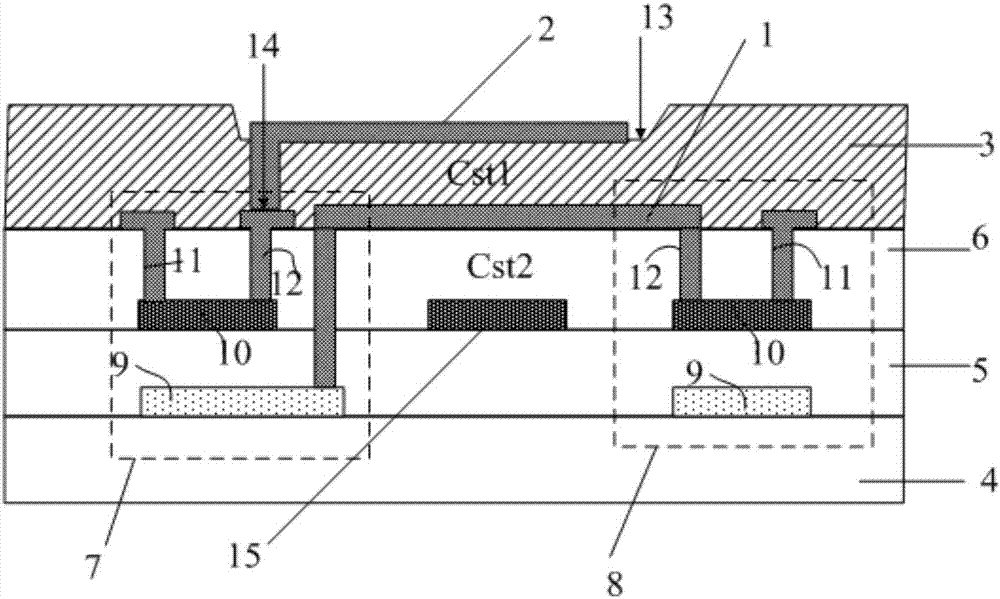

[0049] Based on the same inventive concept, an embodiment of the present invention also provides a method for preparing an array substrate, such as Figure 4 shown, including:

[0050] S401, forming a driving transistor and a switching transistor on a base substrate, and forming a pattern of a first electrode of a first capacitor, wherein the first electrode of the first capacitor is respectively connected to a gate electrode of the driving transistor and a source electrode of the switching transistor;

[0051] S402, forming a pattern of a passivation layer covering the first electrode of the first capacitor, and the passivation layer is provided with a groove and a via hole penetrating through the passivation layer in a region corresponding to the first electrode of the first capacitor;

[0052] S403, forming a pattern of the second electrode of the first capacitor in the groove, and connecting the second electrode of the first capacitor to the source of the driving transisto...

Embodiment 1

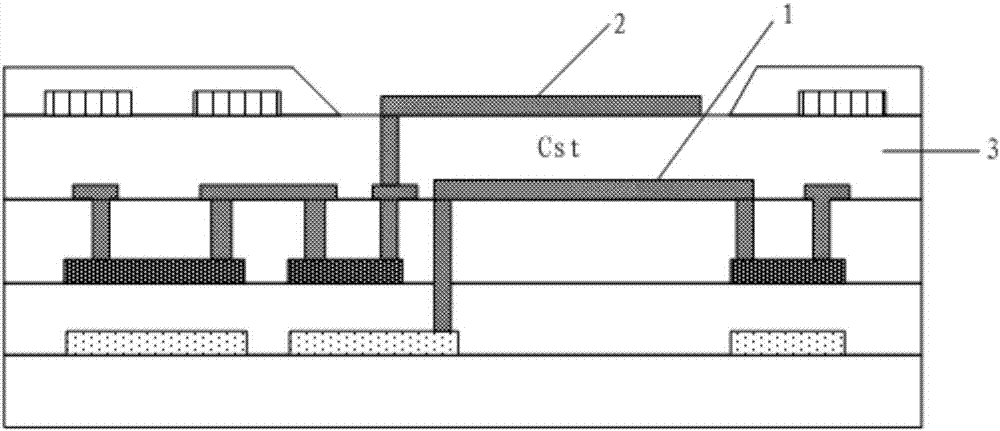

[0056] Taking an array substrate including 3 transistors and 1 capacitor as an example, the preparation method of the array substrate specifically includes:

[0057] 1. A gate electrode 9, a gate insulating layer 5, an active layer 10, an etching stopper layer 6, a drain electrode 11 or a source electrode 12, and a passivation layer 3 are sequentially formed on the base substrate 4 through a patterning process, such as Figure 5a shown;

[0058] 2. Coating photoresist 16 above the passivation layer 3, such as Figure 5b shown;

[0059] 3. Irradiating the photoresist 16 with a half-tone mask or a gray-tone mask to form a via area corresponding to the I region and a groove region corresponding to the II region on the photoresist 16, wherein the half-tone mask The slab or gray tone mask includes a transparent area I, a semi-transparent area II and a light-shielding area III, such as Figure 5c shown;

[0060] 4. Form a via hole 14 penetrating through the passivation layer at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com