Preservative based on gamma-aminobutyric acid combined with lactobacillus plantarum and application thereof

A technology of Lactobacillus plantarum and aminobutyric acid, applied in the application field of Agaricus bisporus fresh-keeping, can solve the problems of lack of versatility and reference, and have not seen common use, etc., to achieve good practical value and commercial promotion Application prospect, safe and non-toxic fresh-keeping effect, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The antistaling agent based on γ-aminobutyric acid combined with Lactobacillus plantarum provided in this example is prepared by the following steps:

[0038] (1) Culture of Lactobacillus plantarum

[0039] Inoculate the obtained original slant-preserved Lactobacillus plantarum strain into the sterilized MRS broth culture solution, culture at 37°C and 150rpm for 16-24 hours, and then repeat the subculture twice under the same conditions;

[0040] The MRS broth culture solution consists of: peptone 10g / L, beef powder 5g / L, yeast powder 4g / L, glucose 20g / L, sodium acetate 5g / L, dipotassium hydrogen phosphate 2g / L, magnesium sulfate 0.2g / L, manganese sulfate 0.05g / L, triammonium citrate 2g / L, Tween 801mL / L, and the balance is water;

[0041] (2) Preparation of clear water suspension of Lactobacillus plantarum

[0042] Centrifuge the culture solution of Lactobacillus plantarum in step (1) at 12000rpm for 10min, collect the precipitated bacteria, wash with clean water no ...

Embodiment 2

[0068] The antistaling agent provided by the present embodiment, its preparation method is the same as embodiment 1, only adjusting the number of Lactobacillus plantarum cells in the antistaling agent is 10 7 cfu / mL, the final concentration of GABA in the preservative is 100 μg / mL.

[0069] When utilizing the antistaling agent to process Agaricus bisporus, the processing method is the same as in Example 1, only adjusting the soaking time to be 3min.

[0070] The experimental results are shown in Tables 4 to 6 below.

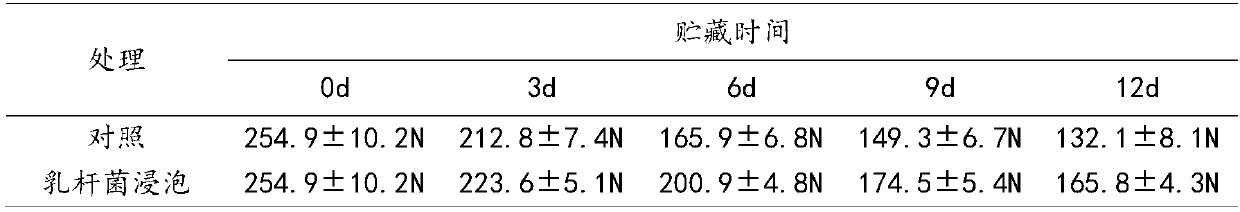

[0071] Table 4, the influence of different fresh-keeping treatments on the hardness of Agaricus bisporus

[0072]

[0073] Table 5, the effect of different preservation treatments on the L* value of Agaricus bisporus

[0074]

[0075] Table 6, the effect of different fresh-keeping treatments on the weight loss rate of Agaricus bisporus

[0076]

[0077] From the analysis of the data in the above table, it can be seen that with the prolongation of stor...

Embodiment 3

[0079] The antistaling agent provided by the present embodiment, its preparation method is the same as that of embodiment 1, only adjusting the number of Lactobacillus plantarum cells in the antistaling agent is 5 * 10 6 cfu / mL, the final concentration of GABA in the preservative is 150 μg / mL.

[0080] When utilizing the antistaling agent to process Agaricus bisporus, the processing method is the same as in Example 1, only adjusting the soaking time to be 5min.

[0081] The experimental results are shown in Tables 7 to 9 below.

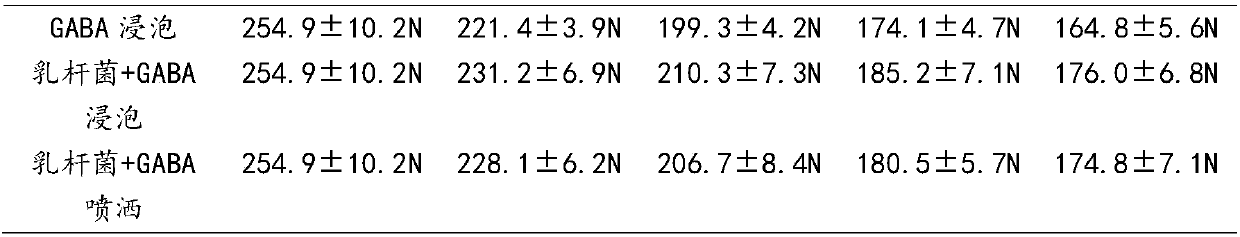

[0082] Table 7, the effect of different fresh-keeping treatments on the hardness of Agaricus bisporus

[0083]

[0084] Table 8, the effect of different preservation treatments on the L* value of Agaricus bisporus

[0085]

[0086] Table 9, the effect of different fresh-keeping treatments on the weight loss rate of Agaricus bisporus

[0087]

[0088] From the analysis of the data in the above table, it can be seen that with the prolongation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com