CO2 energy storage device for realizing circular power generation by using biomass combustion

An energy storage device and cyclic power generation technology, which is applied in the direction of fuel, combustion method, combustion type, etc., which are burned in a molten state, can solve problems such as insufficient efficiency, and achieve the effects of flexible adjustment and utilization, pollution reduction, and high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

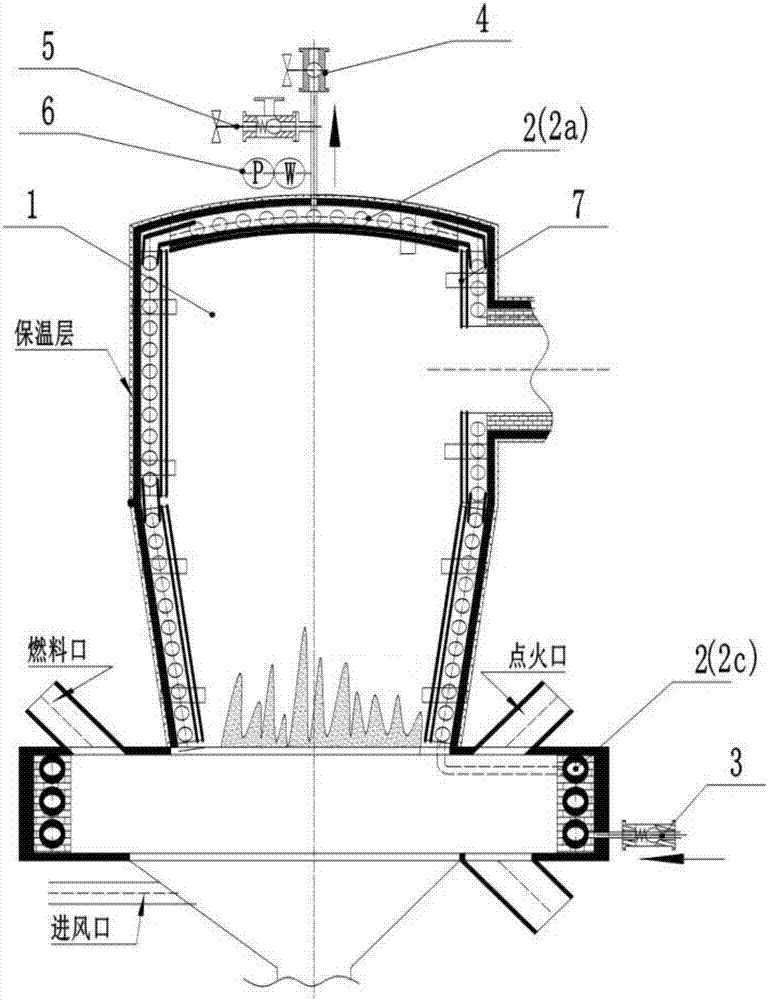

[0036] Such as figure 1 As shown, the present invention provides a CO that utilizes biomass combustion to realize cycle power generation 2 Energy storage device, biomass furnace 1 is boiling furnace, CO 2 Fluid energy storage mechanism 2, check valve 3, regulating valve 4, safety valve 5, temperature and pressure sensor 6, support and hanger 7; the fluidized fluidized furnace also includes a high temperature zone, a fuel port, an air inlet, an ignition port, and an ash outlet , smoke outlet and preheating zone, the fuel port, air inlet, ignition port, and ash outlet are all arranged in the preheating zone; the high temperature zone is adjacent to the preheating zone; the CO 2 The fluid energy storage mechanism 2 adopts a plate heat exchanger 2a, which is fixed on the inner wall of the fluidized fluidized furnace or embedded in the refractory material of the inner wall through the support bracket 7, and the outer wall of the fluidized fluidized furnace and the CO 2 An insulat...

Embodiment 2

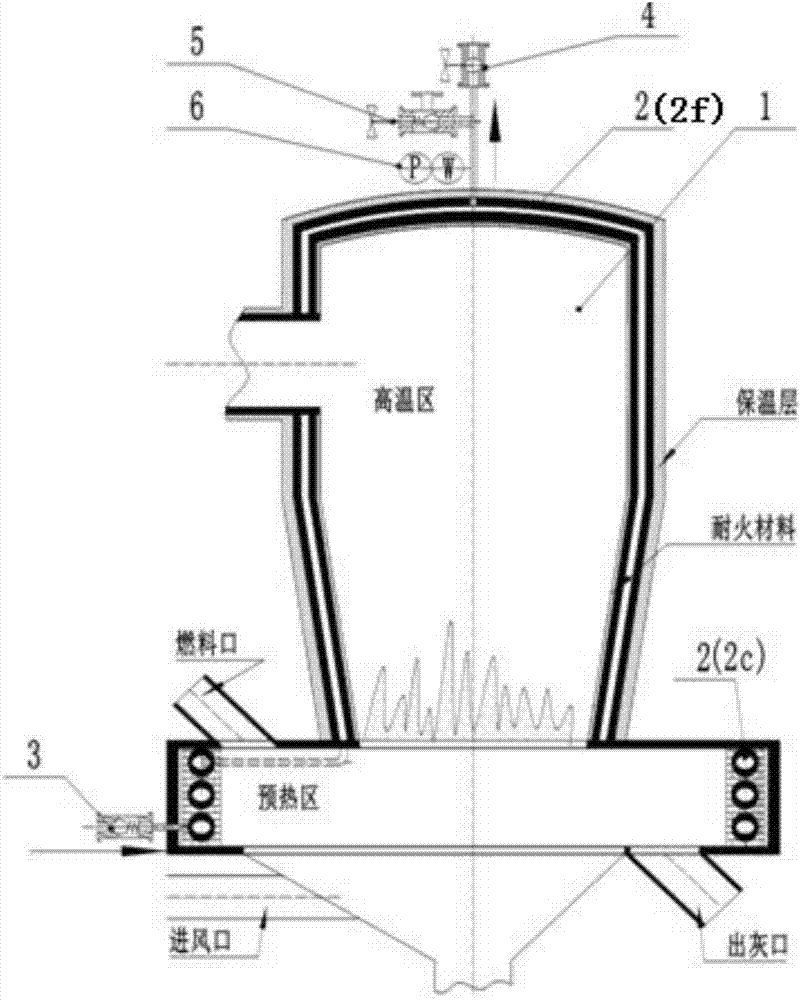

[0040] Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the CO 2 The fluid energy storage mechanism 2 adopts a jacketed heat exchanger 2f, and the jacketed heat exchanger 2f is embedded and fixed on the inner wall of the fluidized furnace or embedded in the refractory material of the inner wall, and the outer wall of the fluidized furnace and the CO 2 An insulation layer is arranged between the fluid energy storage mechanism 2; the CO 2 The fluid energy storage mechanism 2 adopts a disc-type hollow tube heat exchanger 2c, which is fixed on the inner wall of the preheating zone of the fluidized furnace or embedded in the inner wall refractory material.

Embodiment 3

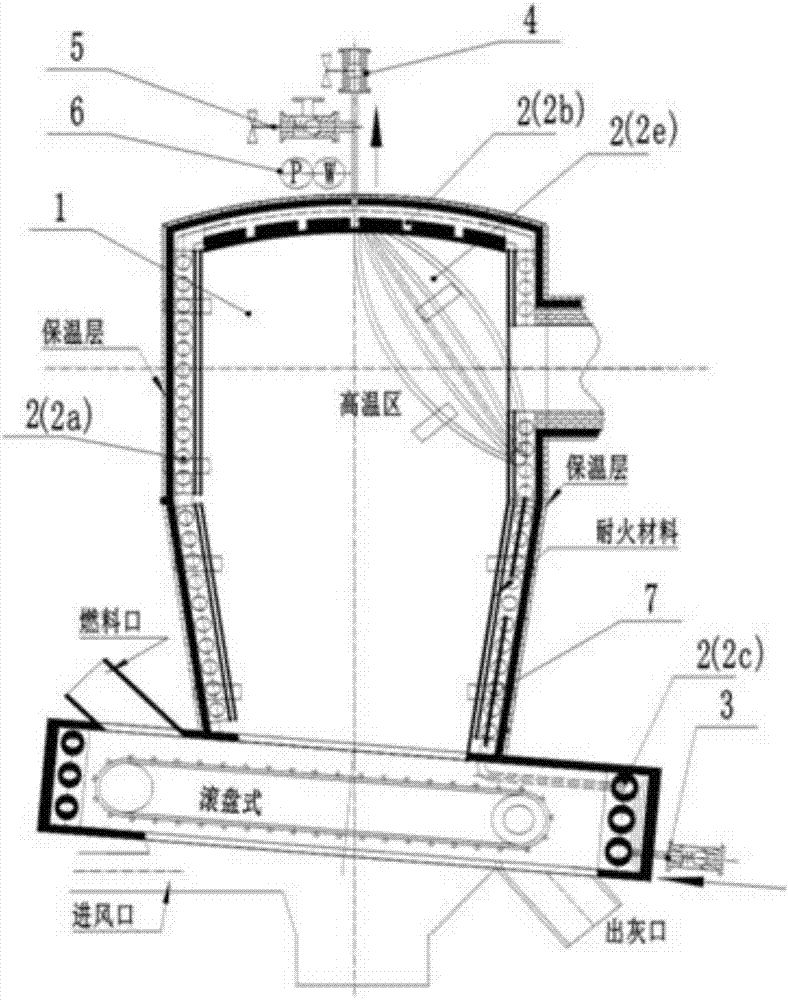

[0042] Such as image 3 As shown, the difference between embodiment 3 and embodiment 1 is that the biomass furnace 1 is a disc furnace, and the CO 2 The fluid energy storage mechanism 2 is composed of various forms. The plate heat exchanger 2a is fixed by a hanger 7 on the inner wall of the disc furnace or in the refractory material of the inner wall, and is fixed by a hanger 7 on the inner top of the disc furnace. There is a box-type heat exchanger 2b, and a shell-and-tube heat exchanger 2e is fixed at the smoke outlet of the disc furnace through a hanger 7, and a disc-type hollow tube heat exchanger is arranged in the preheating zone of the disc furnace 2c.

[0043] CO above 2 The fluid energy storage mechanism 2 includes a combination of a plate heat exchanger 2a, a box heat exchanger 2b, a shell and tube heat exchanger 2e, and a disc hollow tube exchanger 2c, and the working medium is CO 2 fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com