A topping robot and its realization method

A robot and robot arm technology, applied in the field of agricultural machinery, can solve problems such as damage to crops, missing or over-topping, and difficult topping, so as to achieve the effects of improving yield and quality, reducing damage, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

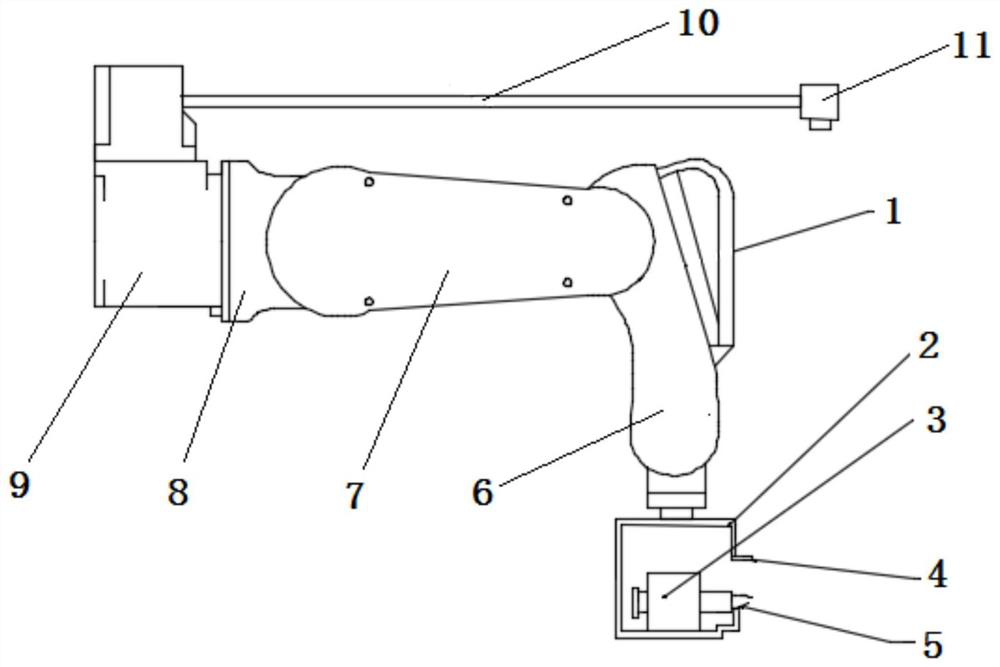

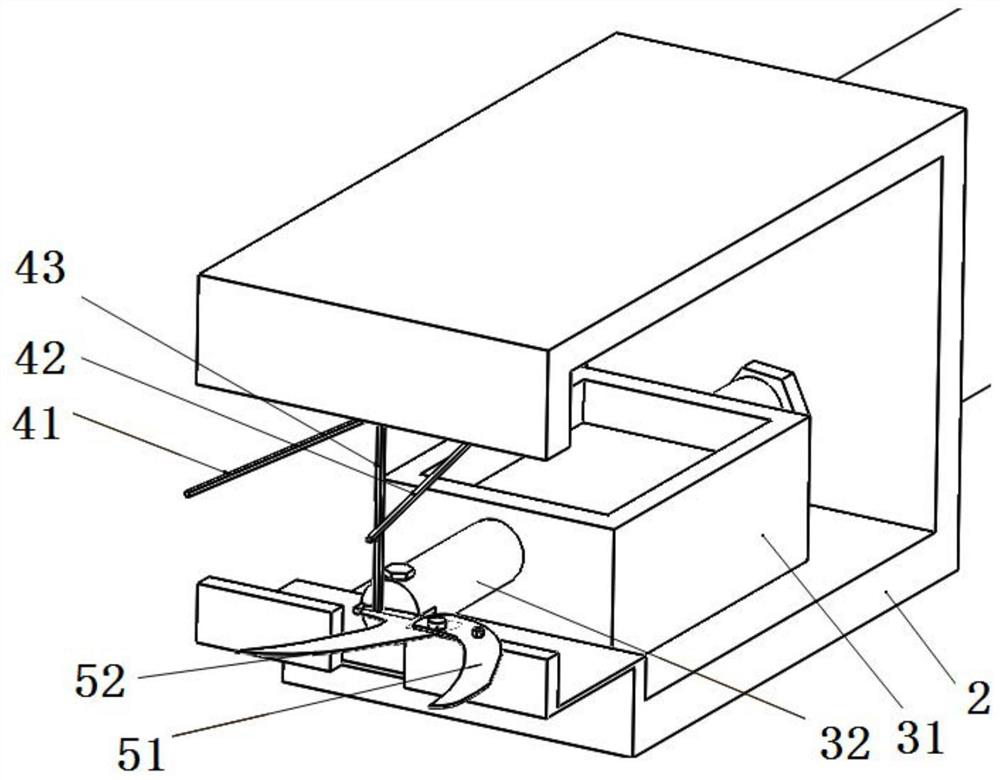

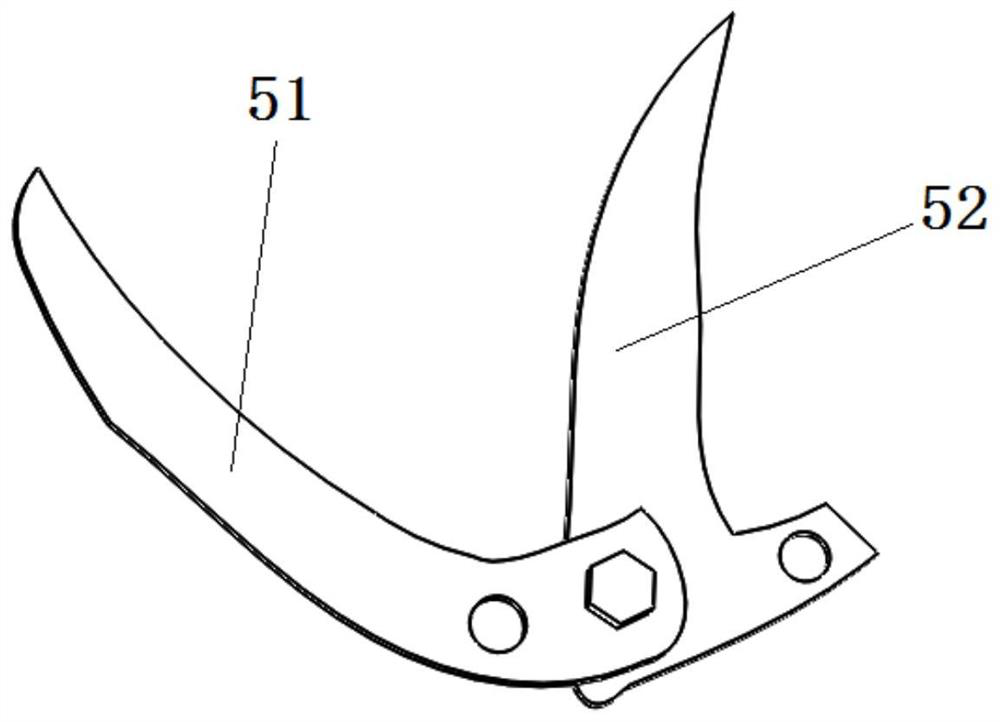

[0030] like Figures 1 to 3 As shown, a topping robot includes a mobile platform, a chassis 9, a waist 8, a connecting rod 10, a visual recognition system 11, a two-joint robot arm 1, a collecting and cutting mechanism 5 and a central processing unit, wherein the chassis 9 is fixed On the mobile platform, specifically, the chassis 9 and the mobile platform are fixed by fastening bolts, the waist 8 is flexibly connected to the chassis 9, and the visual recognition system 11 is connected to the mobile platform through the connecting rod 10. The above-mentioned chassis 9 is connected, and the visual recognition system 11 includes two sets of CCD cameras. Two sets of CCD cameras can be set to obtain images of crop top growth conditions in a manner similar to binocular recogn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com