Method of green plant plasticized specimen and application of obtained specimen

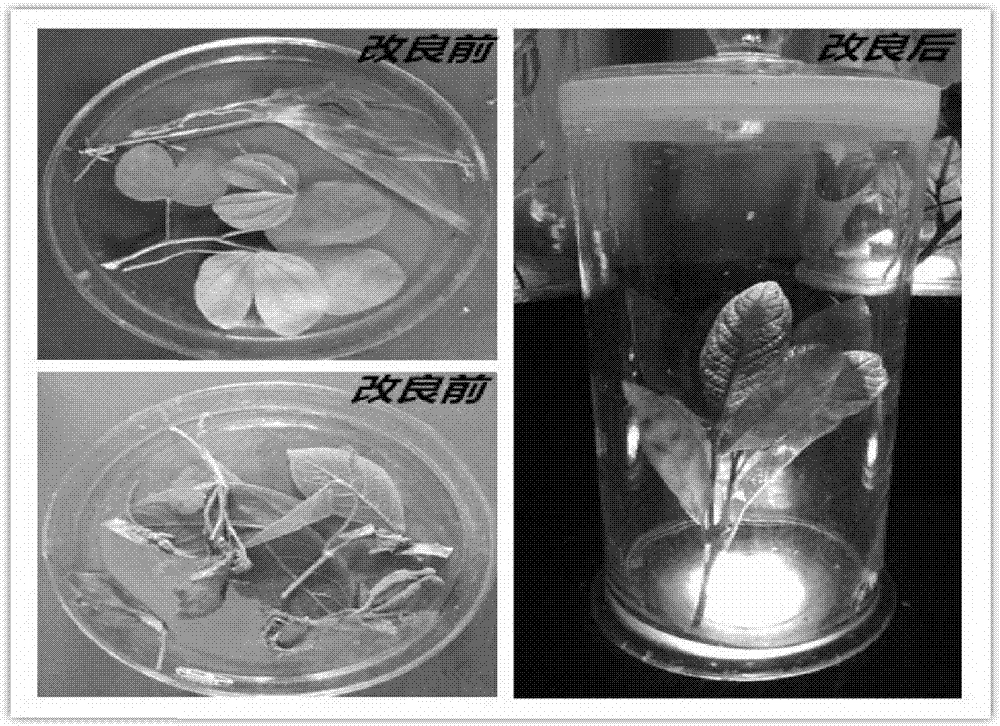

A technology of green plants and specimens, applied in the field of plant specimens, can solve problems such as unfavorable visits and studies, volatile preservation liquid, irritating smell, etc., and achieve the effect of accelerating exchange speed, shortening time, and good plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

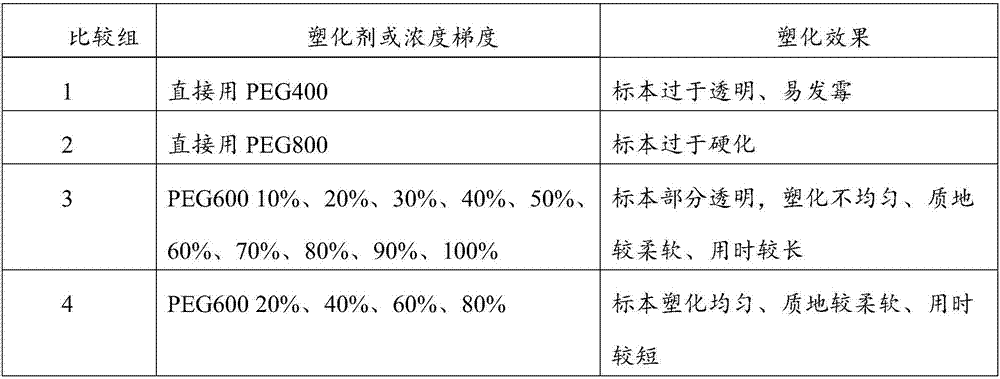

Examples

Embodiment 1

[0035] A method for plasticizing specimens of green plants, comprising the following preparation steps:

[0036] 1. Collection of green plants: Select those with normal growth, complete leaves and flowers and other organs, and no pests and diseases, make a record of picking, wash and moisturize.

[0037] 2. Fixing method of green plants

[0038] 2.1 Preparation of color fixing solution

[0039] Take the copper chloride solid and dissolve it with distilled water to saturation to obtain a saturated solution of copper chloride; then mix the saturated solution of copper chloride with glacial acetic acid (1:4) to finally obtain a color-fixing solution.

[0040] 2.2 Boiling and fixing color

[0041] Pour the color-fixing solution into a glass tank, heat the water bath to a slight boil of about 90°C, and then put the plants in. Soon the color of the green plants will gradually recede and turn into a withered yellow. Continue heating until the green color returns to uniformity; Aft...

Embodiment 2

[0057] 1. the collection of green plants: with embodiment 1.

[0058] 2. Fixing method of green plants

[0059] 2.1 Preparation of color-fixing solution Take copper chloride solid and dissolve it with distilled water to saturation to obtain a saturated solution of copper chloride; then mix saturated solution of copper chloride with glacial acetic acid (1:3) to finally obtain a color-fixing solution.

[0060] 2.2 Boiling and fixing color

[0061] Pour the color-fixing solution into a glass tank, heat the water bath to a slight boil of about 90°C, and put in the plants. Soon, the color of the green plants will gradually recede and turn into a withered yellow. Continue heating until the green color recovers evenly. For specimens that have been successfully color-fixed, rinse the solution on the surface with water and air dry naturally. Continue to put in plants and repeat the above steps. During this process, keep the water bath slightly boiling at about 90°C.

[0062] 3. Plasti...

Embodiment 3

[0069] 1. the collection of green plants: with embodiment 1.

[0070] 2 Fixation method of green plants

[0071] 2.1 Preparation of color-fixing solution Take copper chloride solid and dissolve it with distilled water to saturation to obtain a saturated solution of copper chloride; then mix saturated solution of copper chloride with glacial acetic acid (1:5) to finally obtain a color-fixing solution.

[0072] 2.2 Boiling and fixing color

[0073] Pour the color-fixing solution into a glass tank, heat the water bath to a slight boil of about 90°C, and put in the plants. Soon, the color of the green plants will gradually recede and turn into a withered yellow. Continue heating until the green color recovers evenly. For specimens that have been successfully color-fixed, rinse the solution on the surface with water and air dry naturally. Continue to put in plants and repeat the above steps. During this process, keep the water bath slightly boiling at about 90°C.

[0074] 3 Plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com