Brown yogurt rich in empyreumatique and production method thereof

A burnt aroma and brown technology, applied in the field of brown yogurt and its preparation, can solve the problems of not delicate taste, insufficient burnt aroma and the like, and achieve the effects of remarkable burnt aroma, rich fermentation flavor, and convenience for transportation, carrying and drinking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

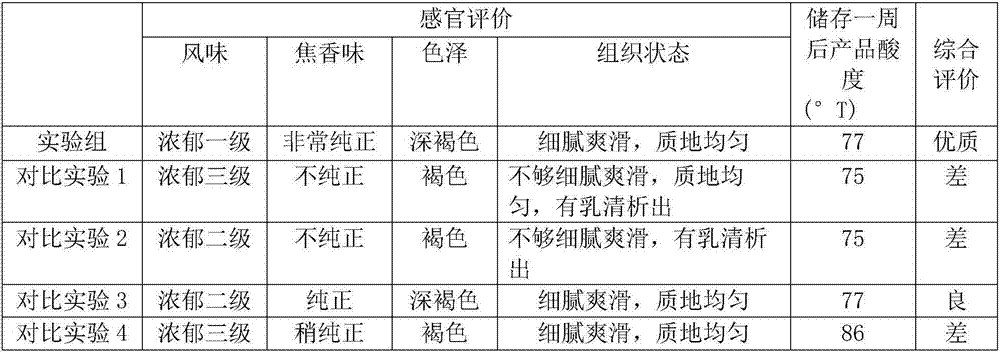

Embodiment 1

[0049] A kind of brown yogurt with strong burnt aroma. Firstly, the milk is screened, then reducing sugar and some white sugar are added, mixed, filtered and then browned. The browned milk, white sugar, stabilizer, concentrated whey protein, monoglyceride , food spices are mixed and then homogenized, sterilized, strain inoculated, fermented, demulsified, refrigerated, aseptically filled, and stored at low temperature. 7.5 parts of syrup, 4 parts of white sugar, 0.5 parts of whey protein concentrate, 0.4 parts of emulsion stabilizer, 0.04 parts of monoglyceride, 0.03 parts of food flavoring, 0.4 parts of caramel syrup and 0.002 parts of bacteria.

[0050] The strain is a mixture of Streptococcus thermophilus and Lactobacillus bulgaricus, and the ratio of Streptococcus thermophilus and Lactobacillus bulgaricus is 5:1.

[0051] Calculated on the basis of 1 kg of fermented milk, the emulsion stabilizer includes the following components: 2.5 g of acetylated distarch adipate, 0.5 g ...

Embodiment 2

[0071] A kind of brown yoghurt with strong burnt aroma. Firstly, the milk is screened, mixed with reducing sugar and some white sugar, filtered and then browned. The browned milk, white sand bran, stabilizer, concentrated whey protein, monoglyceride , food spices are mixed and then homogenized, sterilized, strain inoculated, fermented, demulsified, refrigerated, aseptically filled, and stored at low temperature. The mass percentage of each raw material is 75 parts of liquid milk, fruit 6 parts of glucose syrup, 6 parts of white sugar, 0.3 part of concentrated whey protein, 0.4 part of emulsion stabilizer, 0.02 part of monoglyceride, 0.02 part of food flavoring, 0.2 part of caramel syrup and 0.001 part of bacteria.

[0072] The strain is a mixture of Streptococcus thermophilus and Lactobacillus bulgaricus, and the ratio of Streptococcus thermophilus and Lactobacillus bulgaricus is 4:1.

[0073] Calculated on the basis of 1 kg of fermented milk, the emulsion stabilizer includes ...

Embodiment 3

[0086] A kind of brown yoghurt with strong burnt aroma. Firstly, the milk is screened, mixed with reducing sugar and some white sugar, filtered and then browned. The browned milk, white sand bran, stabilizer, concentrated whey protein, monoglyceride , food spices are mixed and then homogenized, sterilized, strain inoculated, fermented, demulsified, refrigerated, aseptically filled, and stored at low temperature. The mass percentage of each raw material is 90 parts of liquid milk, fruit 8 parts of glucose syrup, 5 parts of white granulated sugar, 0.6 part of whey protein concentrate, 0.4 part of emulsion stabilizer, 0.05 part of monoglyceride, 0.05 part of food flavoring, 0.5 part of caramel syrup and 0.005 part of bacteria.

[0087] The strain is a mixture of Streptococcus thermophilus and Lactobacillus bulgaricus, and the ratio of Streptococcus thermophilus and Lactobacillus bulgaricus is 4.5:1.

[0088] Calculated on the basis of 1 kg of fermented milk, the emulsion stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com