Flip type tea boiling pot

A flip-top, teapot technology, applied in the field of teapots, can solve the problems of affecting the taste of tea leaves, inconvenient to use, easy to burn, etc., and achieve the effects of being beneficial to health, easy to clean, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

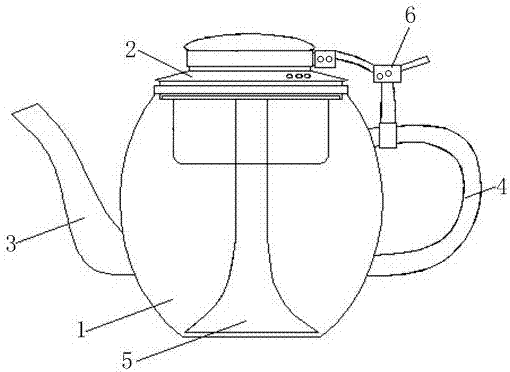

[0045] Such as figure 1 As shown, a schematic diagram of the overall structure of a clamshell teapot, including a body 1, a lid 2, a spout 3 and a handle 4, the lid 2 is arranged at the top opening of the body 1, the spout 3 and the handle 4 are The center line of the kettle body 1 is symmetrically arranged on the side wall of the kettle body 1, which also includes a tea steaming assembly 5 and a connecting assembly 6. The tea steaming assembly 5 is arranged in the kettle body 1 and is detachably connected with the kettle body 1, which is convenient for the tea steaming assembly. 5 for cleaning.

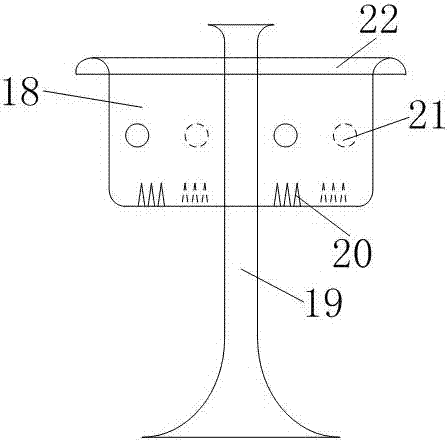

[0046] Such as figure 2 As shown, the structural diagram of the tea steaming assembly 5 includes a tea basket 18 arranged at the top opening of the pot body 1 and a horn conduit 19 running through the center of the tea basket 18. , add cold water through the top of the trumpet conduit 19, so that the cold water does not directly contact the tea leaves, so that the taste of the tea...

Embodiment 2

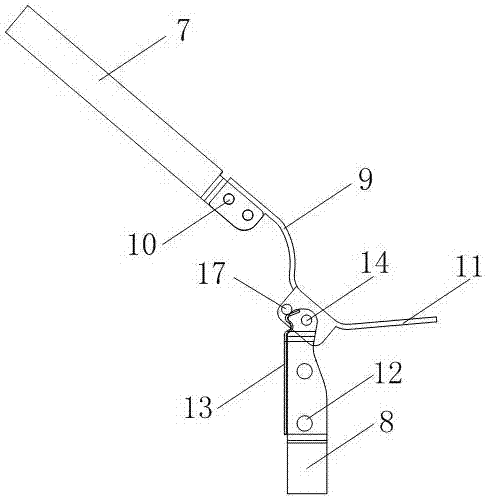

[0050] On the basis of the above-mentioned embodiment, the middle part of the fixed support 8 is fixedly provided with a damping device 13; as Figure 7 As shown, the above-mentioned damping device 13 is a structural schematic diagram, which includes a main body 15 and an S-shaped damping portion 16, the main body 15 is fixed on the fixed bracket 8 by a second rivet 12, and the S-shaped damping portion 16 is arranged on the top of the main body 15; the second connecting portion 28 is also provided with a second pin shaft 17; the second pin shaft 17 and the S-shaped damping portion 16 are used to form a resistance to reduce the closing speed of the pot lid 2 when the pot lid 2 is closed.

[0051] When using, such as Figure 7 As shown, when the second pin 17 is at the S-shaped damping part 16B point position, the pot lid 2 is in the closed state, and the pressing part 11 is pressed to make the second pin 17 rotate around the first pin 14. Due to the S-shaped damping Point C on...

Embodiment 3

[0054] On the basis of the above examples, if figure 2 As shown, the top opening of the above-mentioned trumpet conduit 19 is also set to be trumpet-shaped, and the diameter of the opening at the bottom is greater than the diameter of the opening at the top. A plurality of drains 20 are evenly arranged on the circumference of the junction of the bottom surface of the tea basket 18 and the side wall (preferably four drainage outlets are arranged. mouth 20, three water outlets 20 are set at each place, and the quantity of water outlet 20 can be changed according to actual needs), and a plurality of small holes 21 (preferably four small holes 21, which can be changed according to actual needs) are evenly arranged on the side wall of the tea basket 18 change the number of small holes 21).

[0055] When steaming and boiling tea, cold water is added to the kettle body 1 through the horn opening at the top of the horn conduit 19 to make adding water more convenient, and during the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com