Portable infusion heating device with calcium chloride serving as heat insulation material and manufacturing principle and method thereof

A heating device and thermal insulation material technology, applied in the direction of pharmaceutical equipment, other medical equipment, hypodermic injection equipment, etc., can solve problems such as overheating, inconvenient use, electromagnetic radiation, etc., achieve convenient use, avoid activity reduction, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

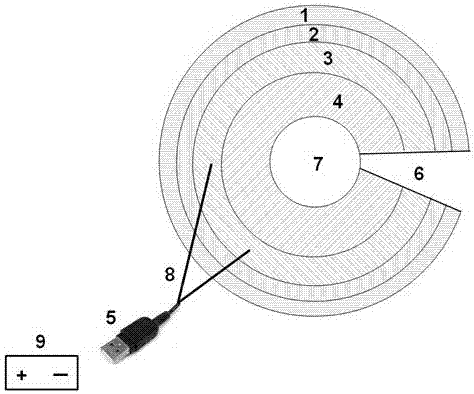

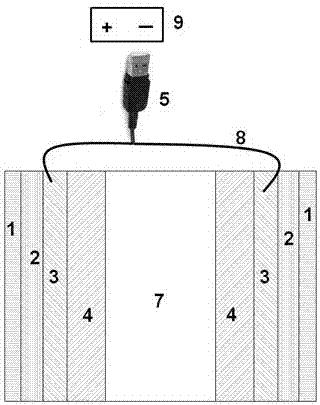

Embodiment 1

[0035] 5g CaCl 2 ·6H 2 O crystal powder is packaged in polyester plastic covered with metal aluminum film as an insulation layer. The resistance 5Ω metal film is printed on the polyester to form a labyrinth circuit, which is used as a heating medium and connected to the USB interface through wires to form a heating layer. Use polyurethane foam with a thickness of 4mm as the insulation layer. After the layers are connected by adhesives, they are packed into a cylindrical polyvinyl chloride plastic protective layer. The USB interface of the heating layer is connected to 220V AC through the charger data cable, and the temperature of the liquid flowing out of the infusion tube is 26~27°C.

Embodiment 2

[0037] 10g CaCl 2 ·6H 2 O crystal powder is packaged in a metal aluminum film with a thickness of 0.1mm as an insulation layer. The resistance 3Ω metal film is printed on the polyester to form a labyrinth circuit, which is used as a heating medium and connected to the USB interface through wires to form a heating layer. Use polystyrene foam with a thickness of 5 mm as the insulation layer. After the layers are connected by adhesives, they are packed into a rectangular polyacrylonitrile-butadiene-styrene (ABS) plastic protective layer. The USB interface of the heating layer is connected to the mobile power supply through the data cable, and the temperature of the liquid flowing out of the infusion tube is 26~28°C.

Embodiment 3

[0039] 7g CaCl 2 ·6H 2 O crystal powder is packaged in a metal copper film with a thickness of 0.1mm as an insulation layer. The resistance 4Ω metal film is printed on the polyester to form a labyrinth circuit, which is used as a heating medium and connected to the USB interface through wires to form a heating layer. Cotton with a thickness of 5mm is used as the insulation layer, and the layers are connected by adhesives, and then put into a rectangular prism-shaped stainless steel protective layer. The USB interface of the heating layer is connected to the USB interface of the notebook through the data cable, and the temperature of the liquid flowing out of the infusion tube is 27~28°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com