High-carbon alcohol emulsion type defoaming agent and preparation method thereof

A defoamer and emulsion-type technology, which is applied in the field of high-carbon alcohol emulsion-type defoamer and its preparation, can solve the problems of poor defoaming effect of defoamers and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

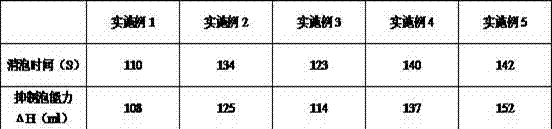

Examples

Embodiment 1

[0033] Step 1, proportioning raw materials. 2 parts palmitic acid, 0.2 parts propylene glycol, 4 parts n-octanol, 6 parts pentaerythritol ester stearate, 5 parts hexacosyl alcohol, 12 parts microcrystalline wax, 2.5 parts emulsifier (1:1 Tween emulsifier and SDS) and 20 parts of water.

[0034] Step 2. Dissolve palmitic acid and propylene glycol in 0.3% water (according to the amount of all water as 1) and stir continuously; then add pentaerythritol ester stearate, hexacosyl alcohol, microcrystalline wax, The emulsifier and 0.1% of all water (calculated as 1) of all water are mixed continuously; then the remaining third part of water is added and continuously stirred to obtain an emulsion.

Embodiment 2

[0036]Step 1, proportioning raw materials. 5 parts of palmitic acid, 0.6 parts of propylene glycol, 10 parts of n-octanol, 20 parts of pentaerythritol ester stearate, 12 parts of hexacosyl alcohol, 30 parts of microcrystalline wax, 7.5 parts of emulsifier (10:3 Tween emulsifier and SDS composition) and 50 parts water.

[0037] Step 2. Dissolve palmitic acid and propylene glycol in 0.5% water (according to the amount of all water as 1) and stir continuously; then add pentaerythritol ester stearate, hexacosyl alcohol, microcrystalline wax, The emulsifier and 0.3 of all water (calculated as 1) of all water are mixed continuously; then the remaining third part of water is added and continuously stirred to obtain an emulsion.

Embodiment 3

[0039] Step 1, proportioning raw materials. 5 parts of palmitic acid, 0.2 parts of propylene glycol, 10 parts of n-octanol, 20 parts of pentaerythritol ester stearate, 5 parts of hexacosyl alcohol, 12 parts of microcrystalline wax, 7.5 parts of emulsifier (7:3 Tween emulsifier and SDS) and 40 parts of water.

[0040] Step 2. Dissolve palmitic acid and propylene glycol in 0.4% water (according to the amount of all water as 1) and stir continuously; then add pentaerythritol ester stearate, hexacosyl alcohol, microcrystalline wax, The emulsifier and 0.2% of all water (calculated as 1) of all water are mixed continuously; then the remaining third part of water is added and continuously stirred to obtain an emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com