Anti-static composite filtering material and preparing method thereof

A compound filtration and anti-static technology, applied in the field of filter materials, can solve the problems of ventilation and air conditioning heat exchange equipment blockage, maintenance, high cost of manual replacement, refrigerant pollution of return air flow, etc., achieve low initial resistance, prevent static electricity and deformation , The effect of convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

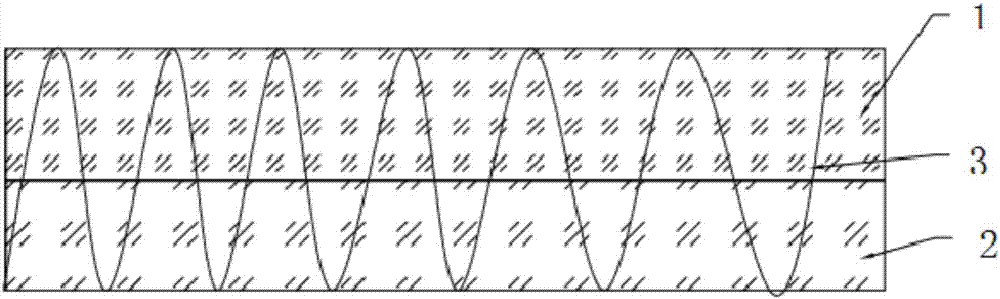

[0028] figure 1 A schematic cross-sectional structure diagram of an antistatic composite filter material according to an embodiment of the present invention is shown. like figure 1 As shown, an antistatic composite filter material includes a first filter layer, a second filter layer and stainless steel wire 3, the first layer of the two filter layers is G5 non-glue cotton 1, and the second layer is G3 non-glue cotton 2. The stainless steel wire 3 is connected with acupuncture hooks to fix the two filter layers.

[0029] Wherein, the G5 non-collodion cotton 1 is added with inorganic flame retardant magnesium hydroxide.

[0030] Wherein, the size of the two filter layers is 7m*1.88m*6mm.

[0031] Wherein, the stainless steel wire 3 is made of SUS316 with a specification of Φ0.2mm.

[0032] A kind of preparation method as aforementioned antis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com