Integrated assembly table of car door welding lines

A technology that integrates assembly tables and welding lines, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as high labor intensity, difficulty in offline production, and long construction period, so as to save operating time, The effect of saving labor costs and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

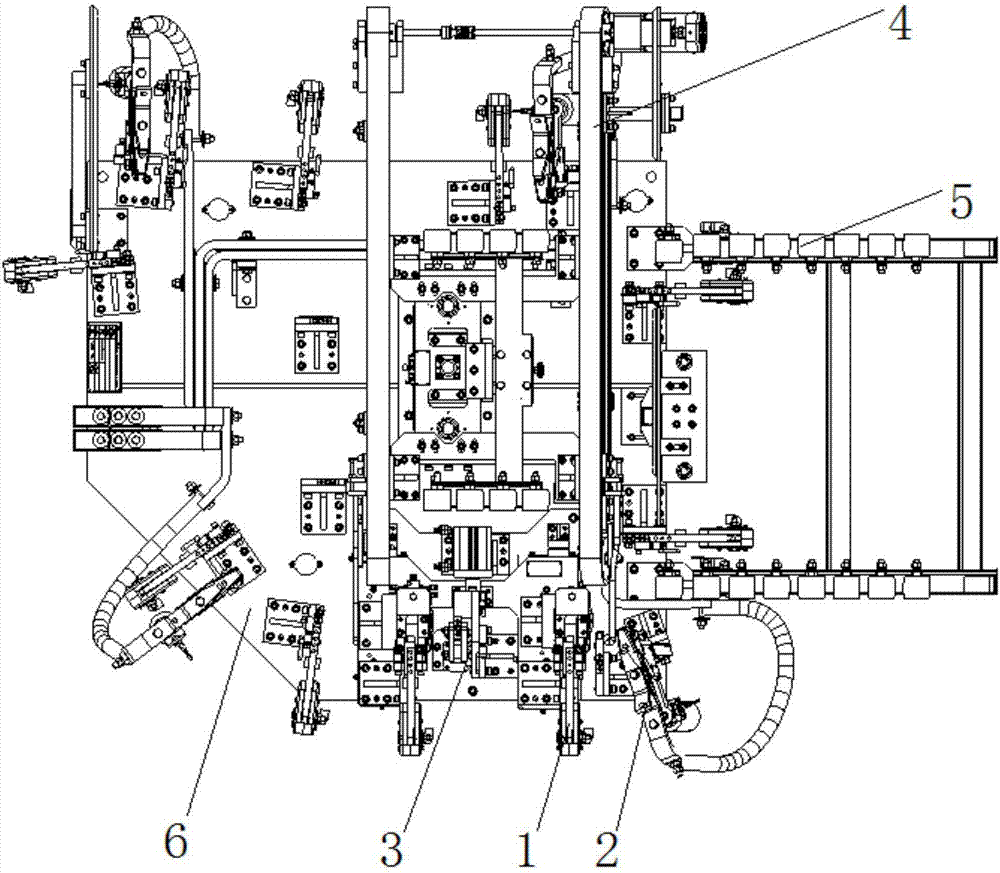

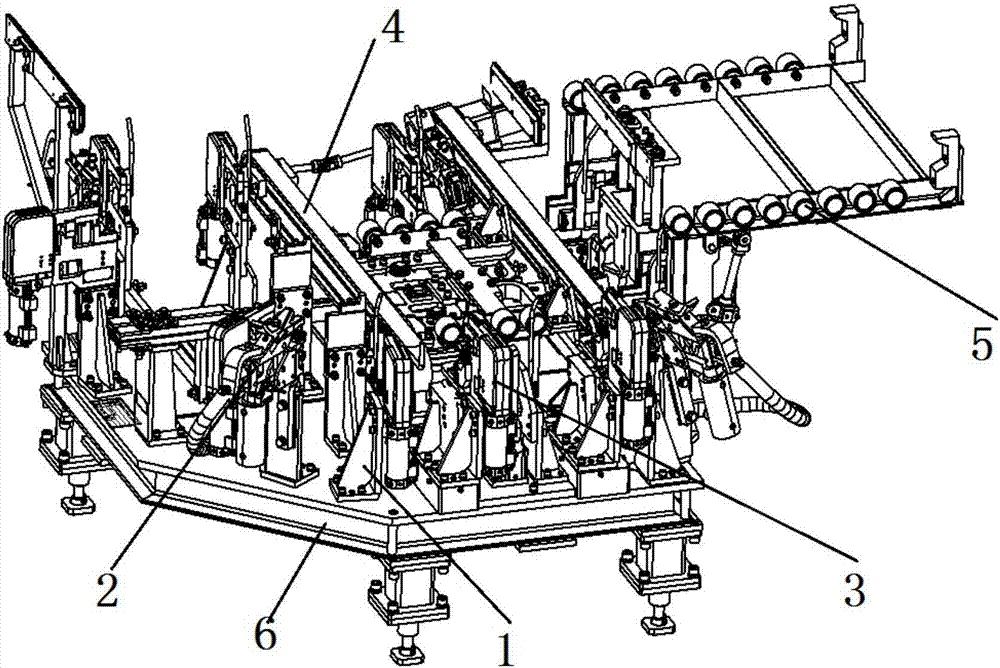

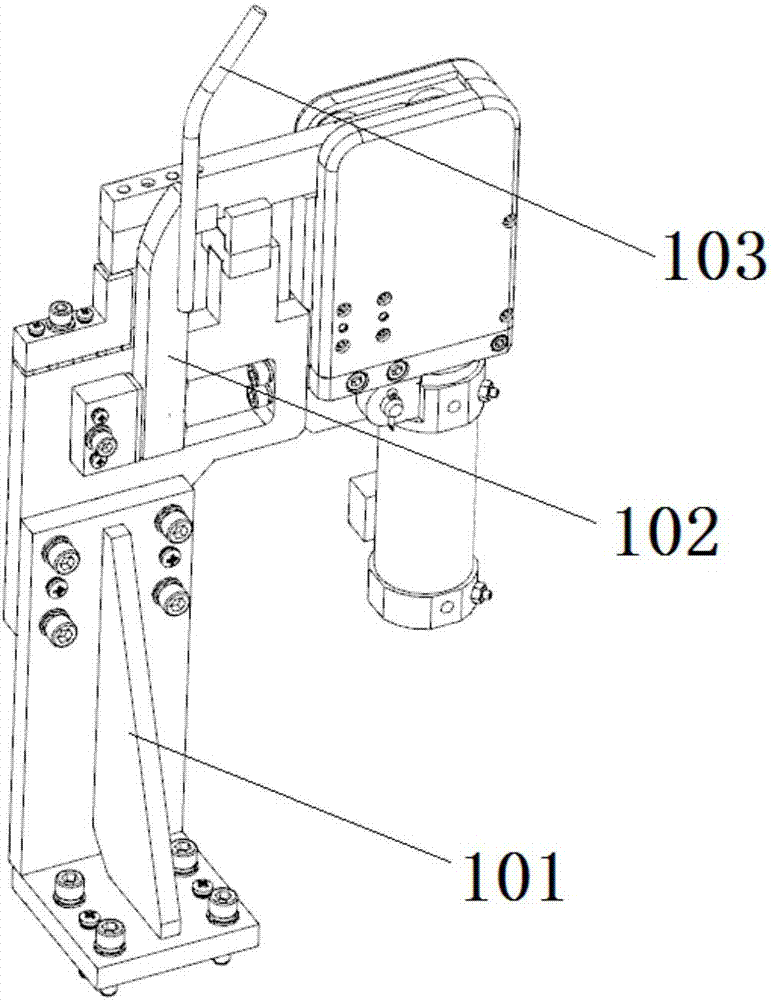

[0028] Such as figure 1 and figure 2 As shown, the present invention includes a platform base 6, an automatic welding mechanism 2, a hinge positioning mechanism 3, a door positioning and clamping mechanism 1, a lifting conveying mechanism 4 and an off-line mechanism 5 arranged on the platform base 6, wherein the The lifting conveying mechanism 4 is used to transport the car door to the specified position on the integrated assembly platform; the car door positioning tightening mechanism 1 is used to fix the car door, and then the car door is welded by the automatic welding mechanism 2; The hinge positioning mechanism 3 is used for positioning the hinge; the offline mechanism 5 is used to remove the welded and hinged car door from the integrated platform.

[0029] In this example, the precision guide positioning of the circle is used. The num...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap