Robot pick-up and packing automation system

An automation system and manipulator technology, applied in the field of machinery, can solve problems such as high cost, low efficiency, and complex structure, and achieve the effects of low error rate, high production efficiency, and increased transportation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

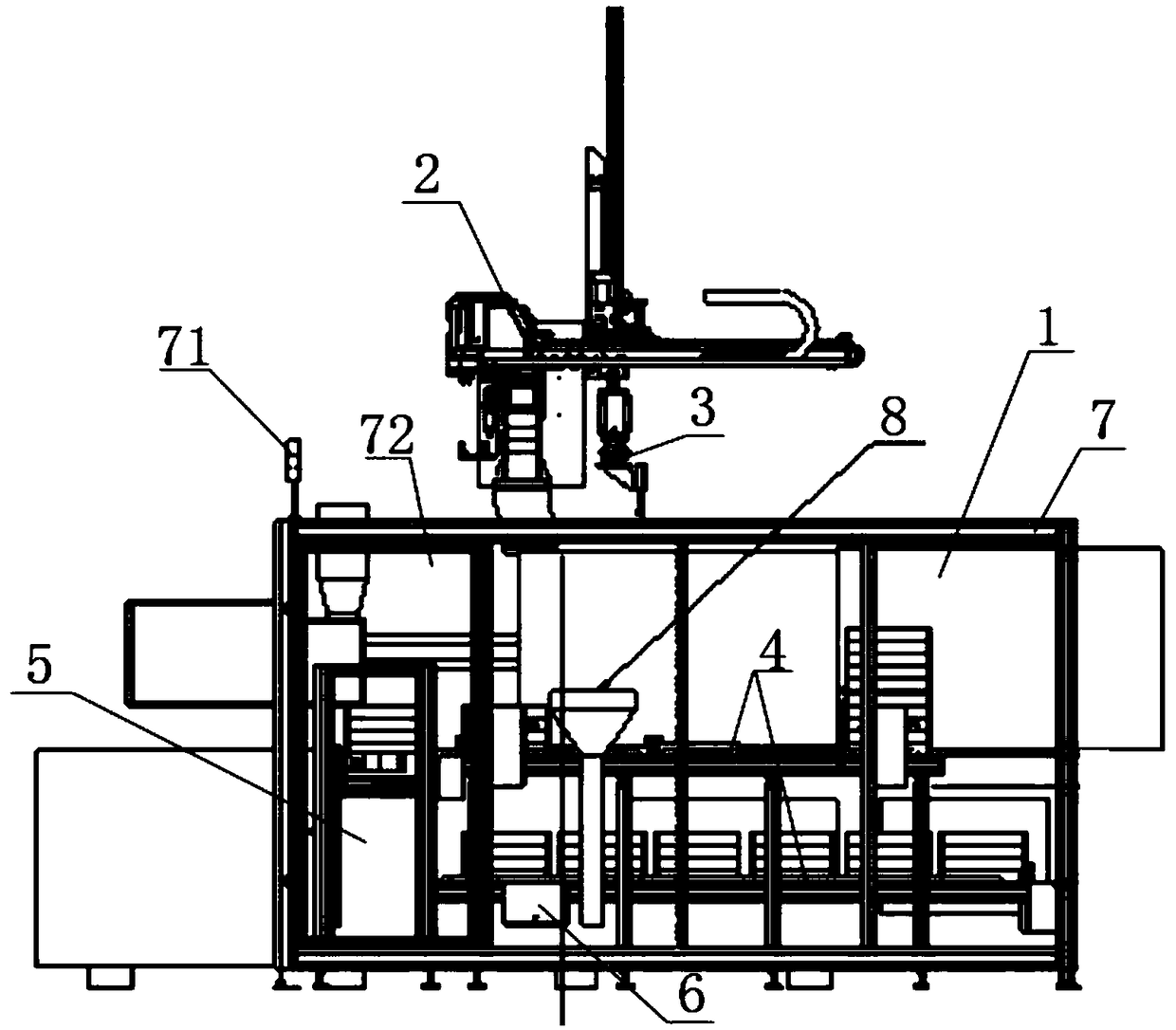

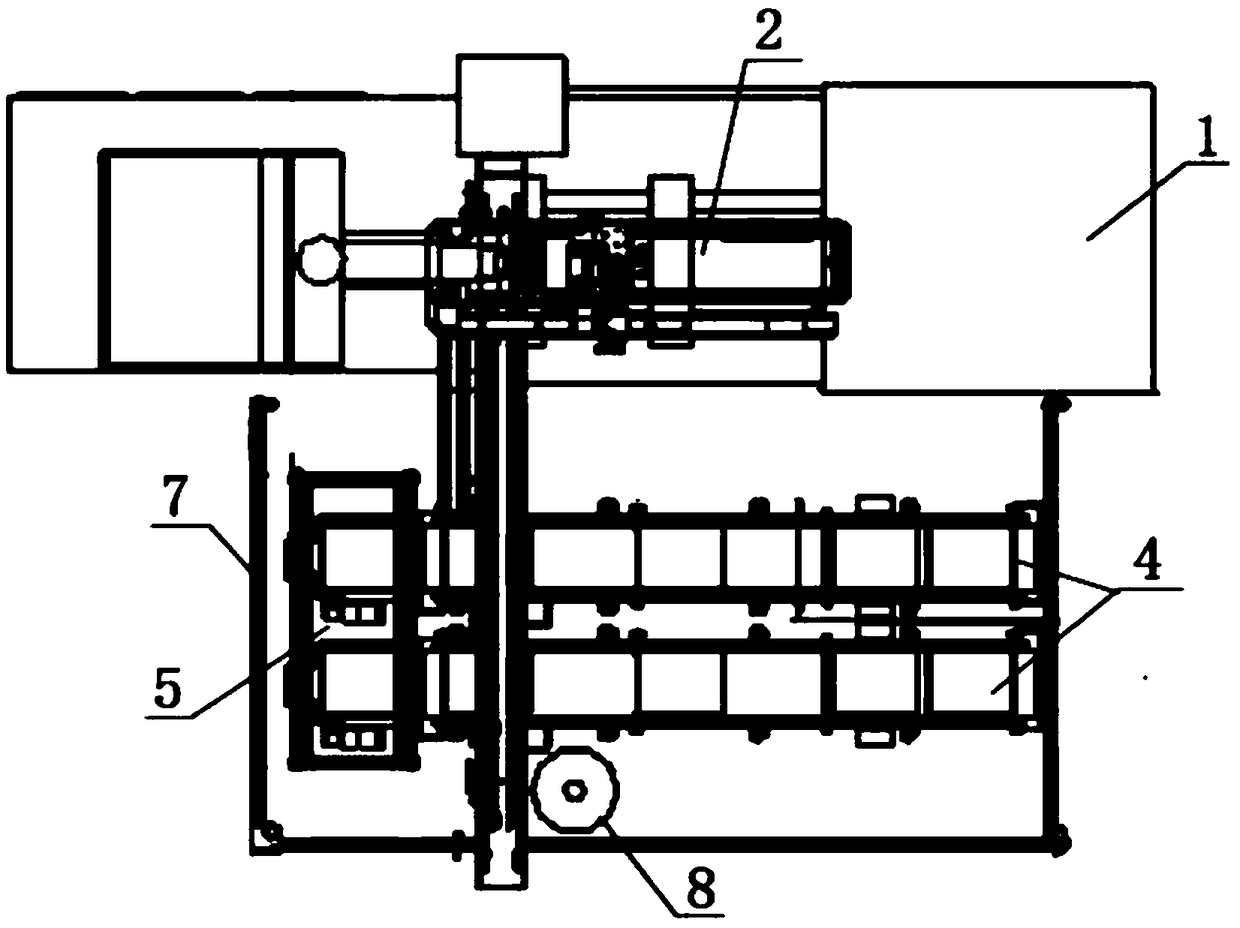

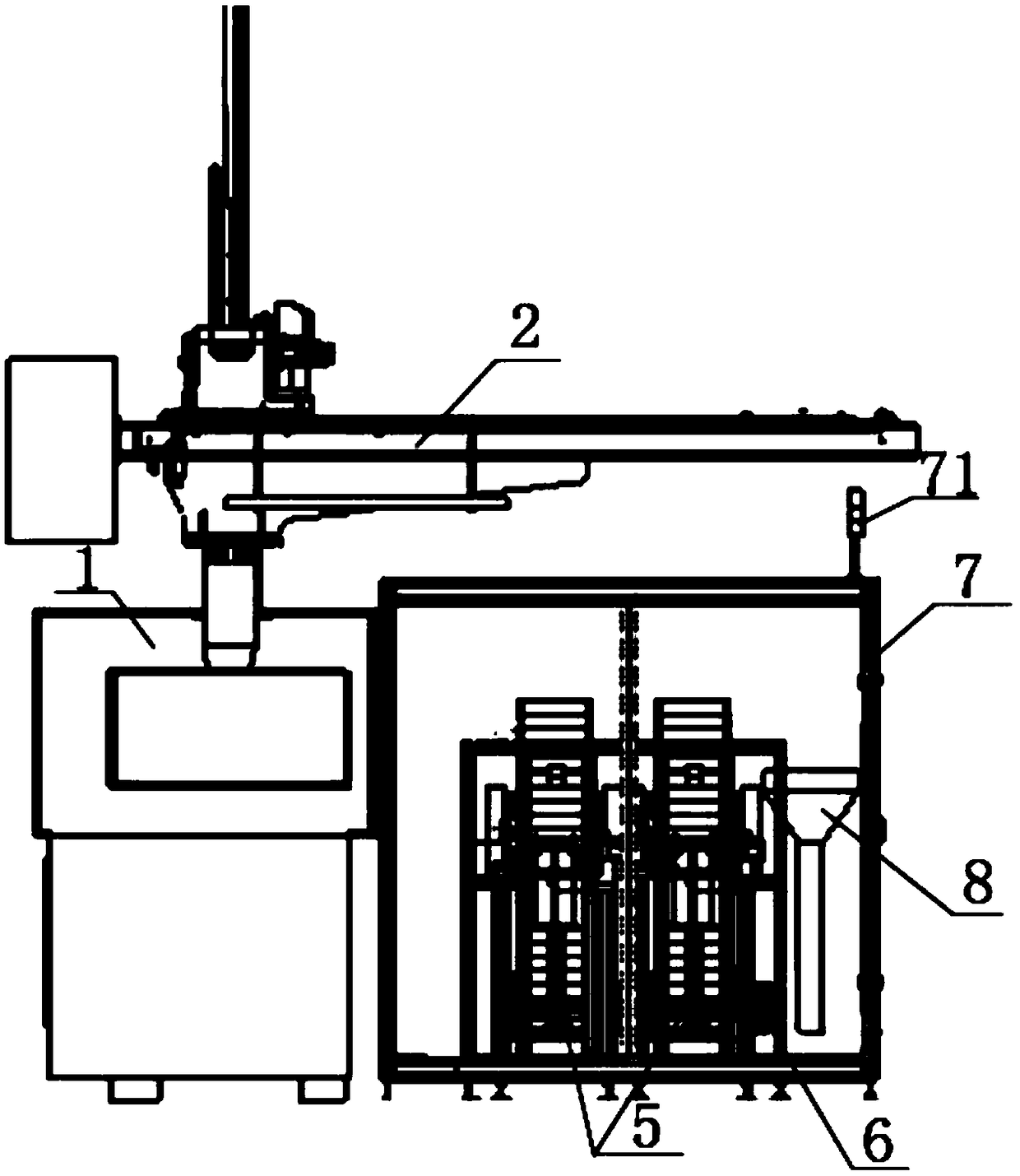

[0033] A kind of manipulator pick-up box automation system, such as Figure 1-7 As shown, it includes an injection molding machine 1, a pick-up manipulator 2, a stackable belt line 4 and an electric control box 6, and two sets of the stackable belt line 4 and the injection molding machine 1 are arranged parallel to each other, and the pick-up The manipulator 2 is installed above the injection molding machine 1; the pick-up manipulator 2 includes a base 21 sequentially connected from bottom to top, a contour unit 22 and a front and rear unit 23, and the contour unit 22 is perpendicular to the front and rear units 23 And can move along described front and rear unit 23 lengthwise, described front and rear unit 23 belows are provided with the pick-up jig 3 that can move along described front and back unit 23 lengthwise; 23 is located directly above the injection molding machine 1 and parallel to the stackable belt line 4 , and the shape-converting unit 22 is located above the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com