A toothpick mold with interdental brush and its manufacturing method

A mold and toothpick technology, which is applied in dentistry, teeth cleaning, gum massage, etc., can solve the problems of difficult mass production of toothpicks with interdental brushes, difficult mass production, difficult to achieve processing accuracy of molds, etc., to solve the problem of oral food residues and Hygienic issues, the realization of mass production, and the effect of widespread promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

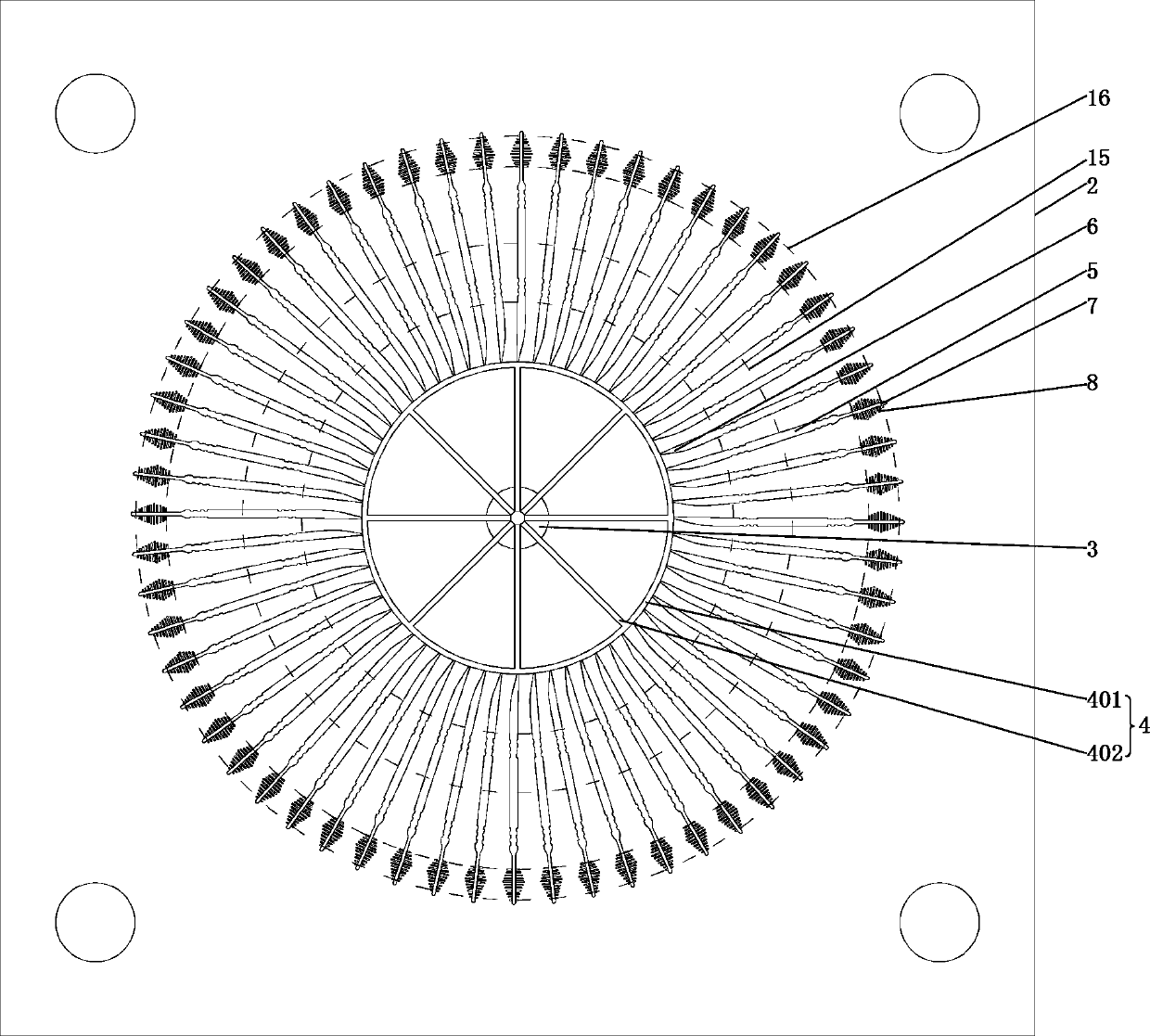

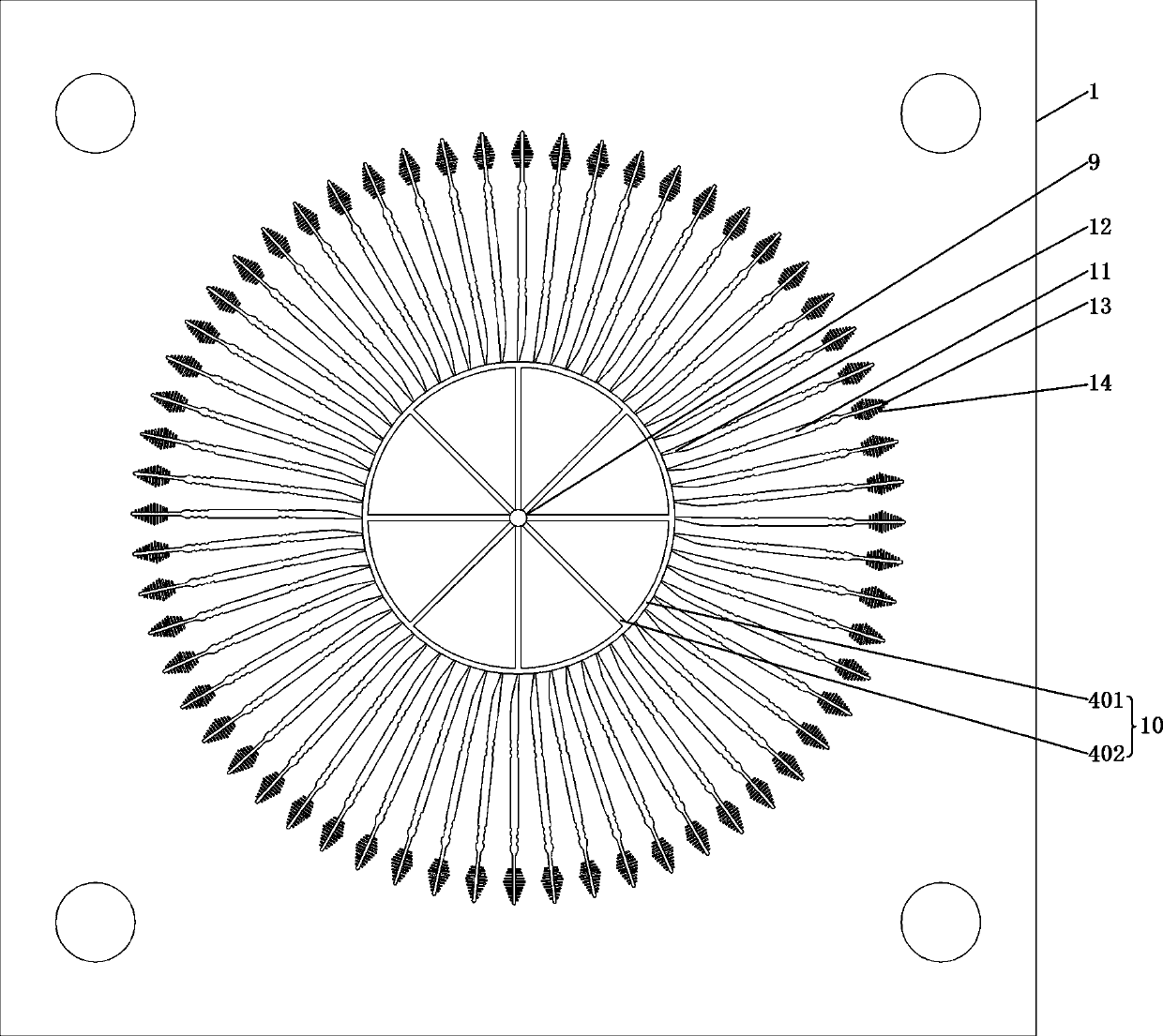

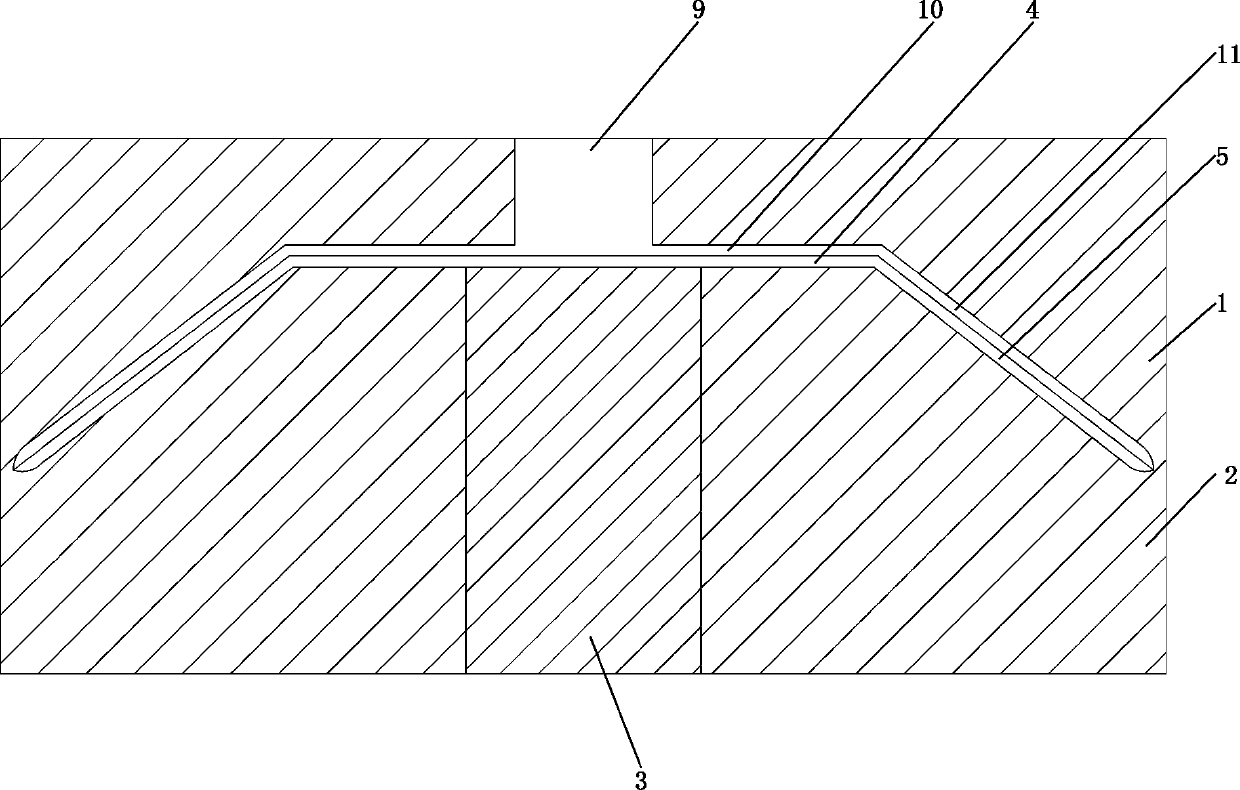

[0032] Such as figure 1 , figure 2 As shown, this toothpick mold with interdental brushes includes an upper mold 1 and a lower mold 2, the lower mold 2 is provided with a demoulding ejector pin 3, and the upper surface of the lower mold 2 is provided with a lower flow channel 4 and a plurality of toothpick lower mold grooves 5. The first tip 6 of the toothpick lower mold cavity 5 is connected to the lower runner 4, and the two sides of the second tip 7 of the toothpick lower mold cavity 5 are provided with a plurality of bristle lower grooves 8; the upper mold 1 is provided with an injection port 9 The lower surface of the upper mold 1 is provided with an upper runner 10 and a plurality of toothpick upper mold grooves 11, the first tip 12 of the toothpick upper mold groove 11 is connected with the upper runner 10, and the second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com