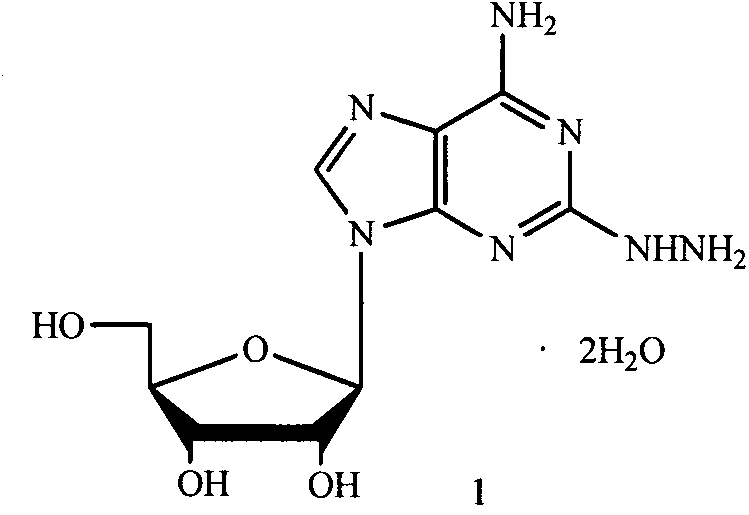

2-hydrazino adenosine and preparation method thereof

A technology of hydrazinoadenosine and hydrazinoadenosine dihydrate, which is applied in the field of medicine and can solve the problems of cumbersome preparation and purification, high cost, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In the method for preparing 2-hydrazinoadenosine dihydrate 1 of the present invention, the amount of hydrazine hydrate is 0.5 to 10 times, preferably 1 to 2 times, the volume of the compound of formula II.

[0027] In the preparation method of the present invention, the reaction solvent may be one or more mixtures of water, methanol, ethanol, n-propanol or isopropanol. Among them, water, methanol or ethanol may be used as a preferable reaction solvent, and methanol is particularly preferable. The amount of the reaction solvent used is 1-10 times, preferably 1-5 times, particularly preferably 2-3 times the volume of the compound of formula II.

[0028] In the preparation method of the present invention, the reaction temperature is 0-100°C, preferably 50-90°C, particularly preferably 80-90°C.

[0029] In the preparation method of the present invention, the reaction time is 1-10 hours, preferably 2-8 hours, particularly preferably 5-7 hours.

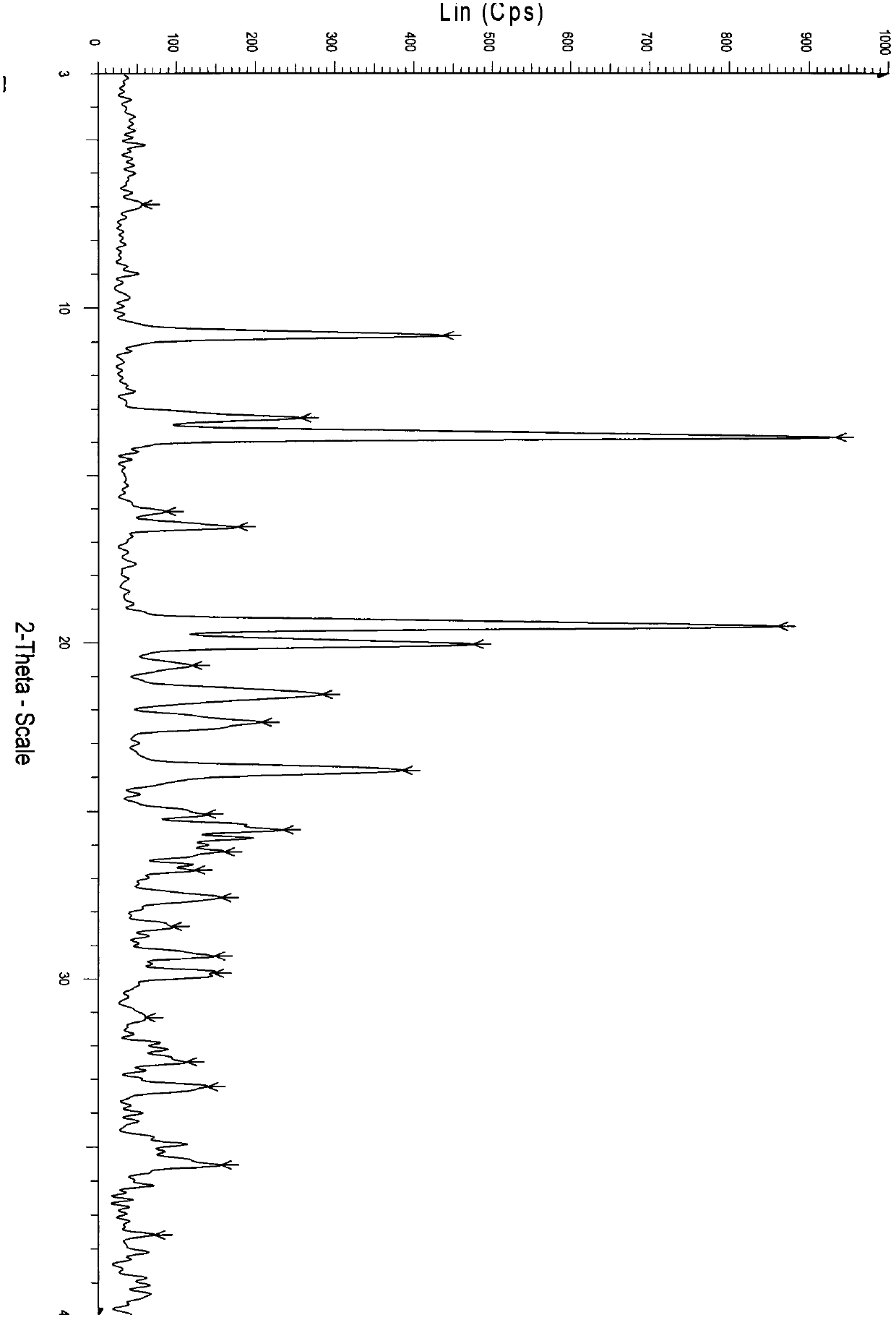

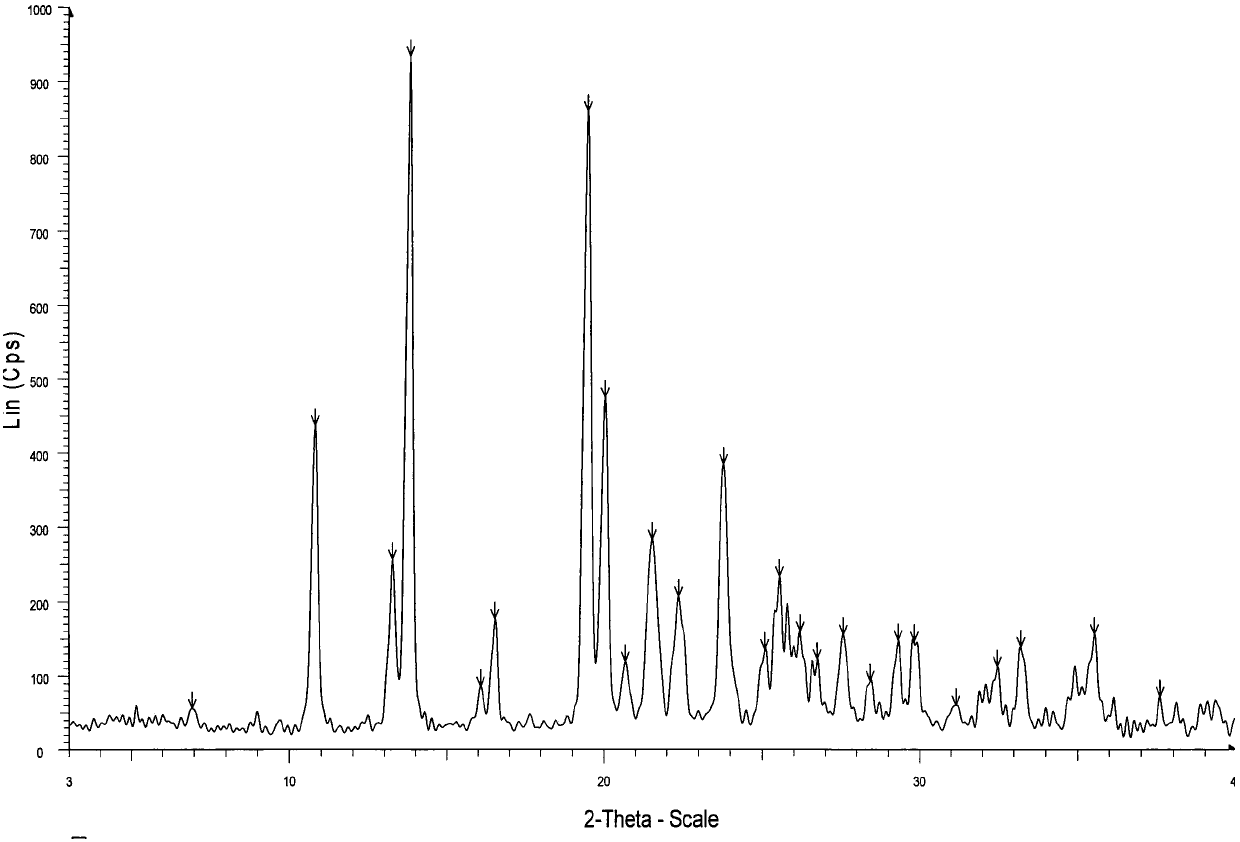

[0030] A crystalline form o...

Embodiment 1

[0037] Example 1: Synthesis of 2-hydrazinoadenosine dihydrate

[0038]

[0039] Add 50g of 2',3',5'-triacetyl-2-chloroadenosine (IIa) into 100mL of hydrazine hydrate, and react at a temperature of 80-90°C for 5h. Cool down to 10-20°C and stir for 1h. Filter, wash with water and ethanol, suck dry, and dry under reduced pressure at 50°C for 6 hours to obtain 31.9 g of off-white solid. Yield 81.9%. Moisture 10.9%, purity (HPLC) 97.4%.

Embodiment 2

[0040] Example 2: Synthesis of 2-hydrazinoadenosine dihydrate

[0041] Add 50g of 2',3',5'-triacetyl-2-chloroadenosine (IIa) into 50mL of hydrazine hydrate and 100mL of ethanol, and react at a temperature of 80-90°C for 5h. Cool down to 10-20°C and stir for 1h. Filter, wash with ethanol, suck dry, and dry under reduced pressure at 50°C for 6 hours to obtain 36.8 g of off-white solid. Yield 94.5%. Moisture 10.8%, purity (HPLC) 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com