Polyester monomer and preparation method thereof as well as polycarboxylate water reducing agent

A monomer and polyester technology, applied in the field of water reducing agent, can solve the problems of short retention time of concrete slump, bleeding, poor slump retention of concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of polyester monomer, comprising:

[0027] At least two isocyanate groups in the isocyanate compound are reacted with the enol compound and the polyglycol monoether, respectively.

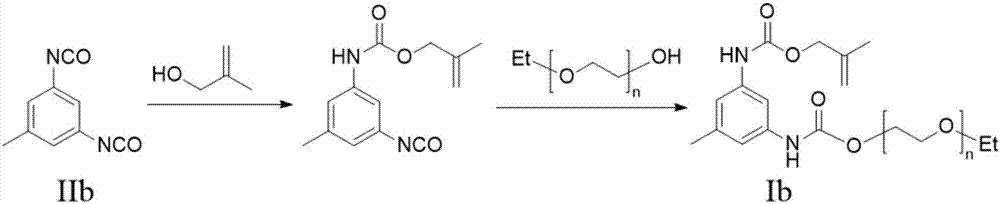

[0028] Among them, the molecular structure of the isocyanate compound used in the embodiment of the present invention contains a linking group, and the linking group includes at least one ring structure, and the ring structure includes C3~C8 cycloalkyl, C3~C8 cycloalkenyl and at least one of the aryl groups. Preferably, the ring structure includes at least one of C3-C6 cycloalkyl, C3-C6 cycloalkenyl and phenyl. The size of the ring structure is larger than the size of the multi-network layered structure of the soil. Therefore, when encountering concrete containing soil, the ring structure will reduce or prevent polycarboxylate superplasticizer molecules from being absorbed into the soil, thereby achieving the effects of soil resistance and water reduction. Through the...

Embodiment 1

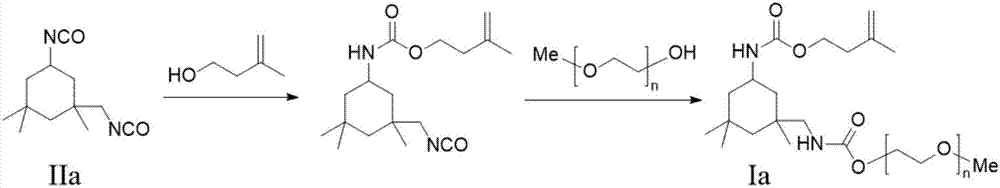

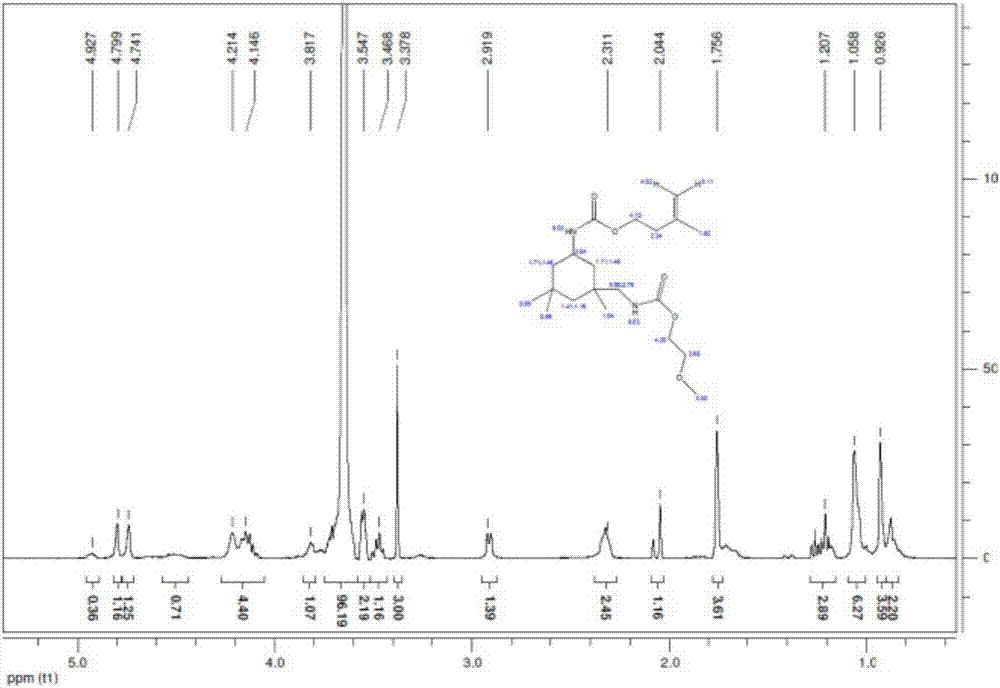

[0044] The present invention provides a kind of polyester monomer Ia, with reference to figure 1 Shown, its preparation method is as follows:

[0045] S1. In a 1000ml four-neck flask equipped with a reflux cooling tube, a stirrer, a thermometer and a dropping device, add 0.55mol of prenyl alcohol and 400ml of ethyl acetate, stir and heat up to 50°C, add 1mol% of Dibutyltin diacetate, under the protection of nitrogen, began to dropwise add the solution of isocyanate compound IIa (0.5mol isocyanate compound IIa dissolved in 200ml ethyl acetate), the dropwise addition was completed after 0.5h, and the reaction was continued for 3h while maintaining the temperature. After the reaction, the polyester intermediate (0.47mol, yield 94%) was obtained through purification.

[0046] S2, add 0.47mol polyester intermediate and 0.47mol polyethylene glycol monomethyl ether in the 1000ml four-necked bottle that is equipped with reflux cooling tube, stirrer, thermometer and dropping device, a...

Embodiment 2

[0048] This embodiment provides a polycarboxylate water reducer, which is obtained by copolymerizing the mixture of polyester monomer Ia and polyether monomer (prenol polyoxyethylene ether) in embodiment 1 with acrylic acid. Wherein, the material ratio of the polyester monomer Ia and the polyether monomer is 1:9. Concrete preparation method is as follows:

[0049] In a 1000ml four-necked bottle equipped with a stirrer, a thermometer, and a dropping device, dissolve 0.02mol polyester monomer Ia and 0.18mol polyether monomer in water, stir and heat up to 40°C, add 0.5mol% trigger After stirring for 5 minutes, a mixed solution of 0.2 mol% reducing agent and 0.5 mol% chain transfer agent, and an aqueous solution of 0.34 mol acrylic acid were added dropwise. The mixed solution of reducing agent and chain transfer agent was dropped within 3 hours, and the aqueous solution of acrylic acid was dropped within 2.5 hours. After the dropwise addition was completed, the temperature was m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com