A kind of preparation method of PDMS superhydrophobic composite coating and coating

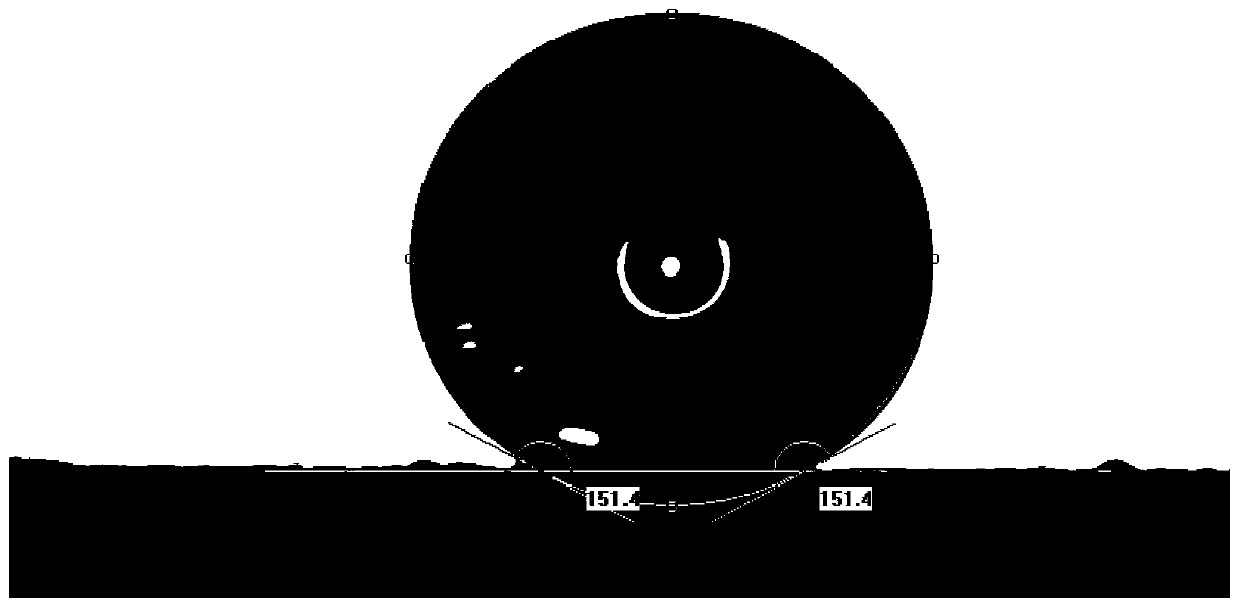

A technology of super-hydrophobic coating and composite coating, which can be applied to coatings, devices for coating liquids on surfaces, special surfaces, etc. Difficulties and other problems, to achieve good thermal stability and chemical stability, improve hydrophobic properties, the effect of small bond energy between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A superhydrophobic coating is prepared by the following steps,

[0034] 1. Prepare the solution

[0035] Liquid A: Commercially available diatomite is ground and added to a mixed solvent (tetrahydrofuran: ethanol = 4:1, V / V), fully oscillated and mixed to obtain a uniform dispersion, wherein the mass-volume concentration of diatomite is 200mg / mL;

[0036] Liquid B: Weigh fluorinated graphite powder and disperse it in dichloromethane solvent, shake and mix well to obtain a stable suspension, wherein the mass-volume concentration of fluorinated graphite powder is 50mg / mL;

[0037] Liquid C: Weigh polyamide powder and dissolve it in tetrahydrofuran solution, shake and mix well to obtain a uniform dispersion, wherein the mass-volume concentration of polyamide is 50 mg / mL;

[0038] Liquid D: Disperse polydimethylsiloxane (PDMS) in tetrahydrofuran solvent (1:1, V / V), oscillate and mix well, and disperse for more than 1 day to obtain a uniform dispersion liquid, in which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com