Road heating mat for melting ice and snow and pavement construction method thereof

A technology for floor mats and road use, which is applied to the field of road heating floor mats and road surface construction, can solve the problems of shortening the service life of the road, taking a long time, and increasing the work flow, so as to improve the utilization rate of heat and improve the efficiency of paving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

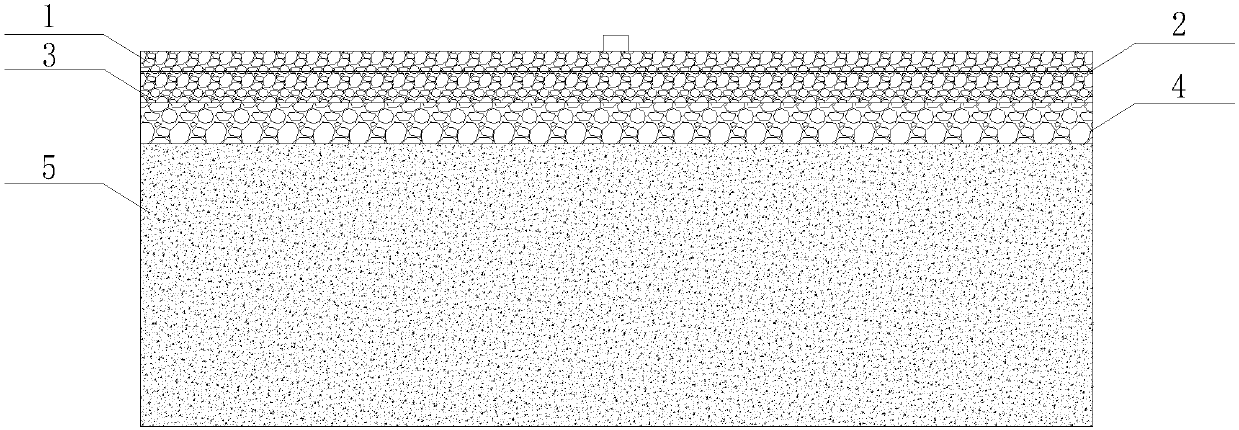

[0061] see figure 1 In the present embodiment, the heating floor mat 2 for the middle road is paved on the middle surface layer 3 of the road, the road base layer 4 is under the middle surface layer 3 of the road, the road foundation 5 is under the road base layer 4, and the road foundation 5 is on the heating floor mat 2. Layer 1 above the road.

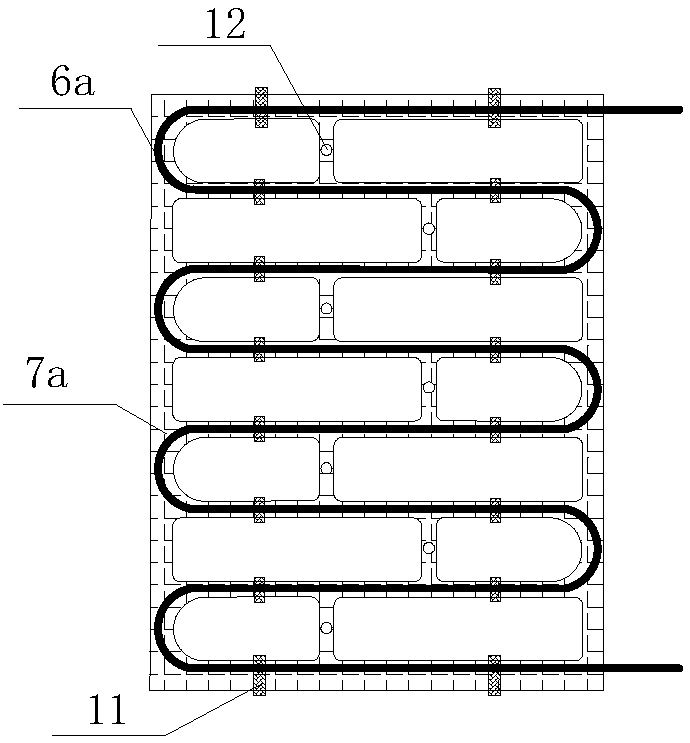

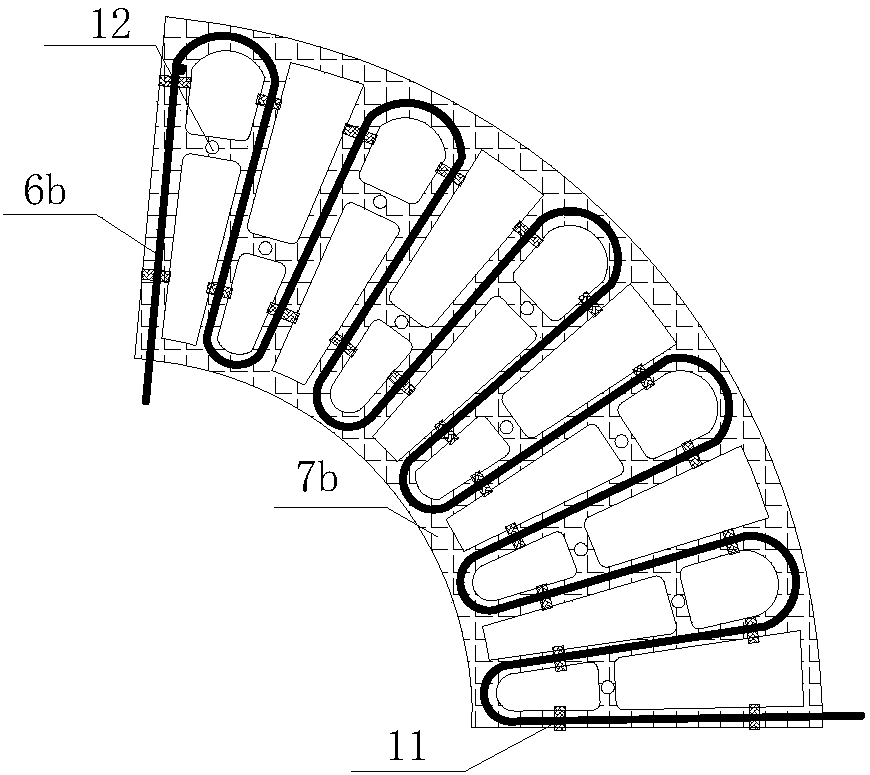

[0062] see figure 2 with image 3 The heating mat 2 is to lay the heating cable 6 on the heat insulation grid 7 arranged according to the plane shape of the road surface, and use the cassette 11 to be fixedly connected with the heat insulation grid 7 to form a prefabricated integral member; the heat insulation grid 7 Made of heat-insulating material, heat-insulating grid 7 is used to set the shape to prefabricate the heating mat 2 into a straight straight mat for paving on straight road surfaces, and a fan-shaped mat for paving on curved road surfaces. The corner mat of the ring.

[0063] see figure 2 , the straight mat is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com