Hollowed cast-in-place pile hole forming structure of rigid rock stratum water grinding drill and construction method

A hard rock formation, water mill drilling technology, applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of loose hole size, large impact of surrounding environment, high blasting technical requirements, etc., to achieve good quality and equipment Simplicity and high molding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with accompanying drawing and embodiment:

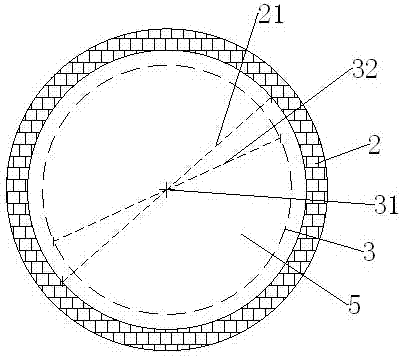

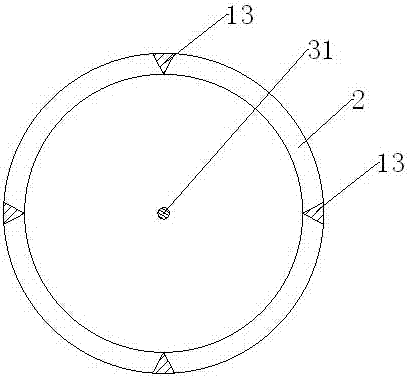

[0043] like Figure 1-4 As shown, a pore-forming structure of water-milled cored piles in hard rock formations includes the core of the body rock 1 and the well circle 2. The well circle 2 is located on the periphery of the core, and the top elevation of the well circle 2 is 300 mm above the ground.

[0044] The well circle 2 is made of rock bricks and M5 cement mortar, and the thickness of the well circle 2 is 240mm. The inner wall of the well circle 2 is coated with a smear layer, which is 1:2 cement mortar with a thickness of 10mm.

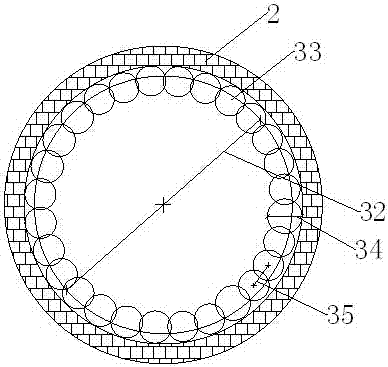

[0045] The inside of the well circle 2 is provided with a circle of pile hole circle 3, the center of circle of the pile hole circle 3 coincides with the circle center of the well circle 2, and the pile hole circle 3 includes several core holes 33, and the intersection between two adjacent core holes 33 makes The core center dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com