Electric drive two-gear gearbox high-speed high-performance synchronizer

A gearbox and high-performance technology, applied in the direction of mechanical drive clutches, clutches, mechanical equipment, etc., can solve the problems of complex structure, high cost, synchronous ring ablation, etc., and achieve broad market prospects, small footprint, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

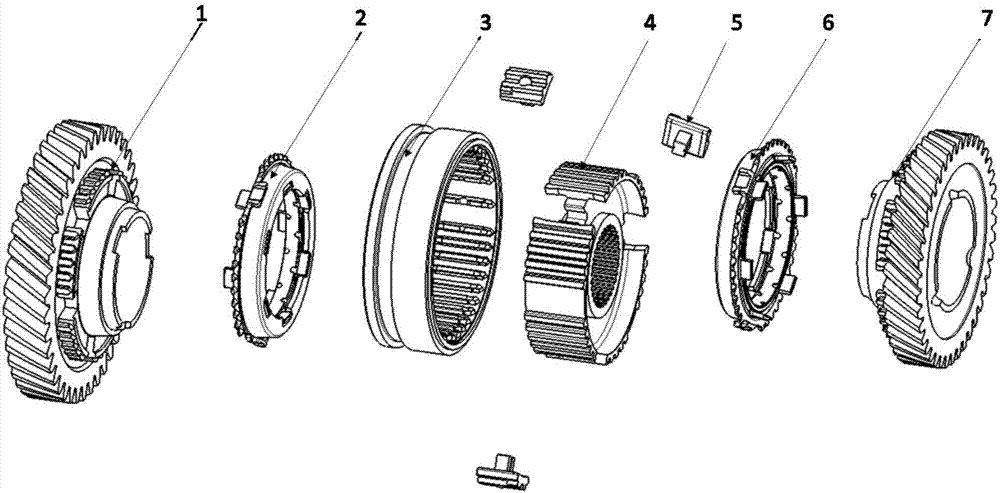

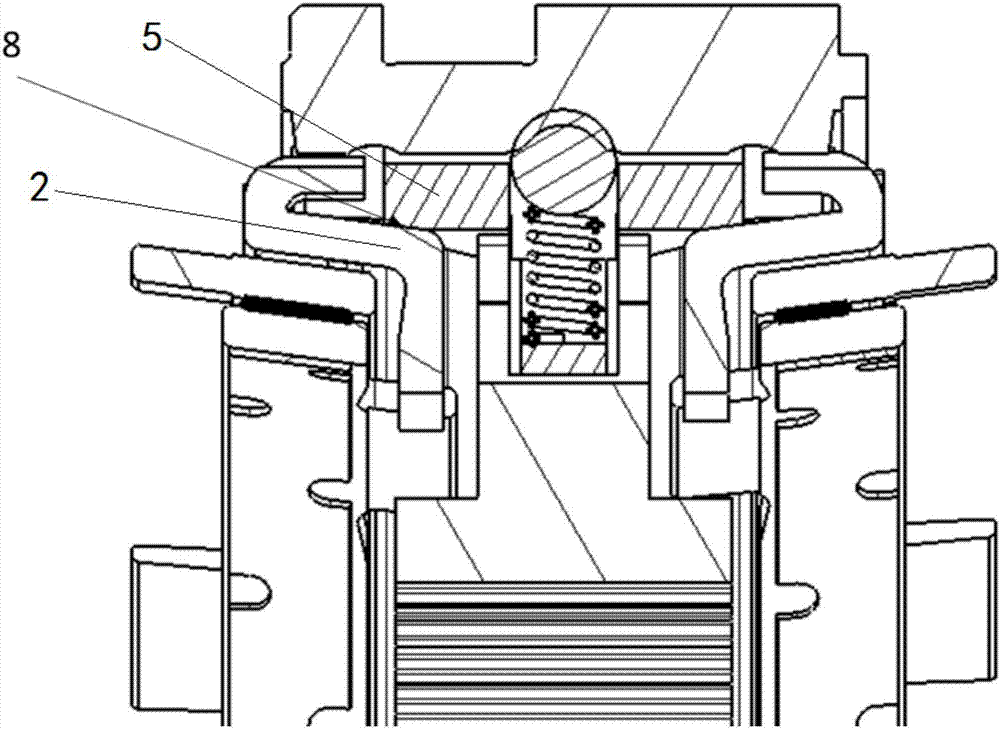

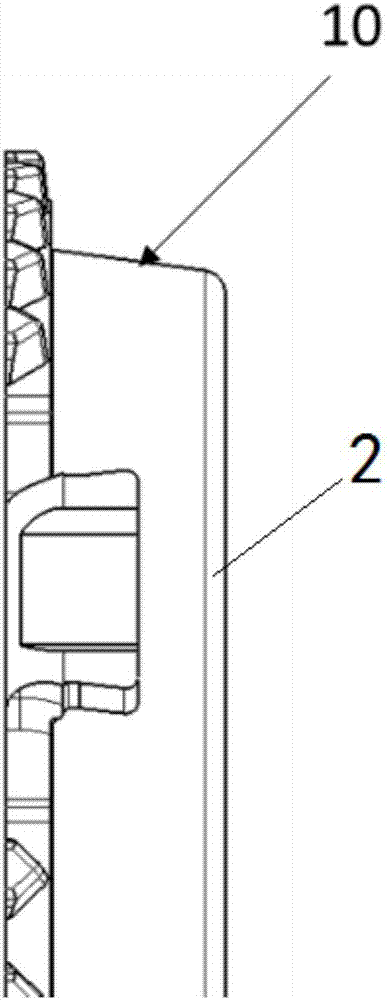

[0025] see Figure 1-6 , a high-speed, high-performance synchronizer for an electric drive two-speed gearbox, including a first-speed combined tooth 1, a first-speed synchronous ring assembly 2, a tooth sleeve 3, a gear hub 4, an anti-shake slider 5, and a second-speed synchronous ring assembly 6 and the second gear combination tooth 7; the gear hub 4 is installed on the shaft through a spline interference fit, and when the shaft rotates, the gear hub 4 is driven to rotate, and the gear hub 4 is connected with the gear sleeve 3 by spline fit, and the gear hub 4 is along the Its circumferential direction is evenly provided with a plurality of slider grooves matching with the anti-shake slider 5, the anti-shake slider 5 is installed in the slider groove, the anti-shake slider 5 is provided with a spring groove, and a spring is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com