Test method of universal characteristic of diesel engine

A technology with universal characteristics and test methods, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as prolonging the development cycle, increasing exhaust pressure, and small air intake, and achieving faster Efficiency and the effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

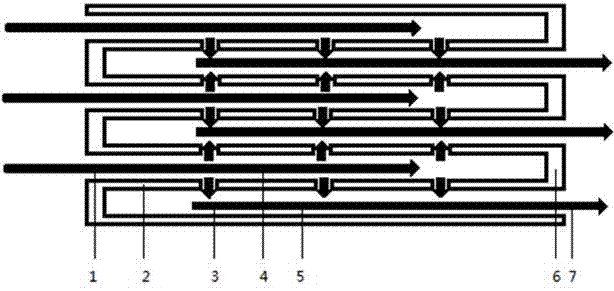

[0018] Such as figure 1 As shown, the existing diesel particulate filter includes a cavity, which is divided into several intake air passages 4 and exhaust air passages 5 by the pipe wall 2. One end of the cavity 1 is provided with an air intake hole 1, and the cavity The other end of the body 1 is a particle trapping plate 6; the middle section of the tube wall 2 is provided with a number of air holes 3; the exhaust gas flow enters the air intake channel 4 of the particle trap from the air intake hole 1 of the cavity, and the gas part Enter the adjacent exhaust passage 5 through the air hole 3 on the pipe wall 2 and then flow out from the air outlet 7. The particles continue to hit the particle collection plate 6 at the bottom of the intake passage 4 due to inertia, and are thus trapped by the particles. Plate 6 captures; however, in operation, some particles are inevitably absorbed due to various effects when passing through the air hole 3, and as time accumulates, the air h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com