Satellite-borne electronic equipment backboard

A technology for electronic equipment and backplanes, applied in the aerospace field, can solve the problems of low reliability, lack of backplane-level dual redundancy support, and high design risks, so as to reduce engineering risks and costs, and achieve rapid integration and application capabilities. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

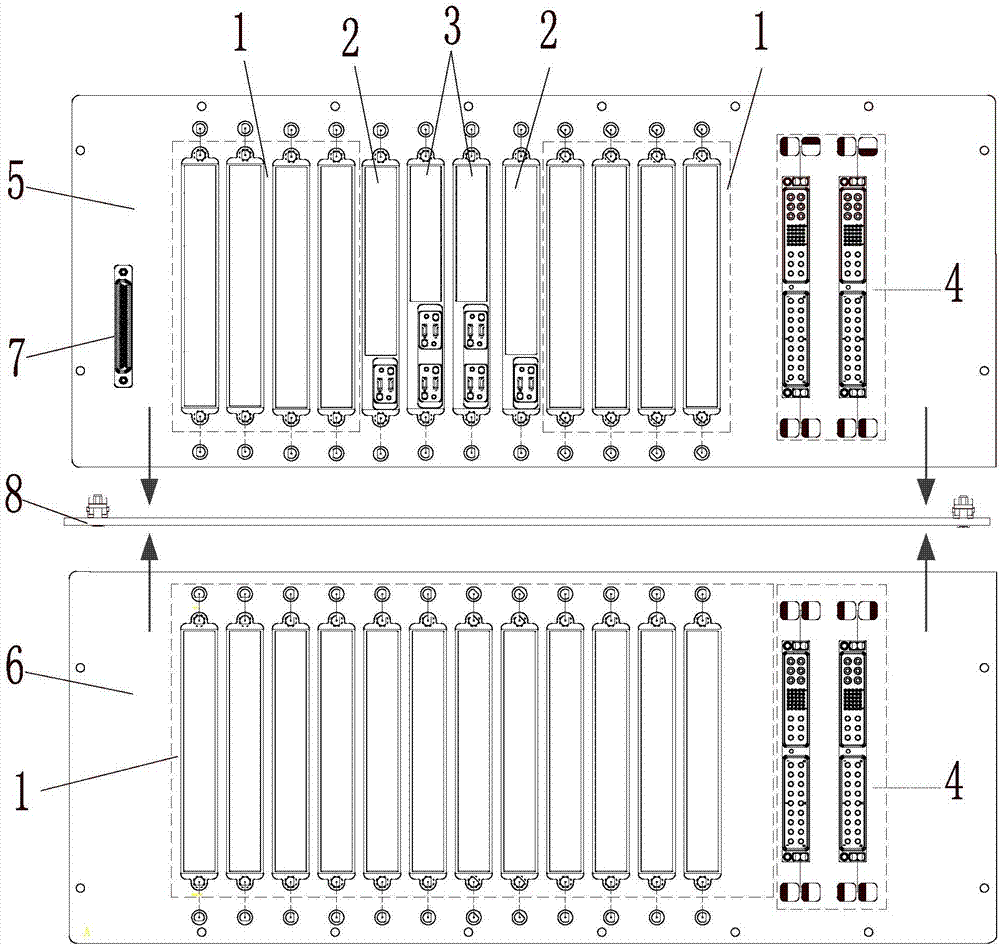

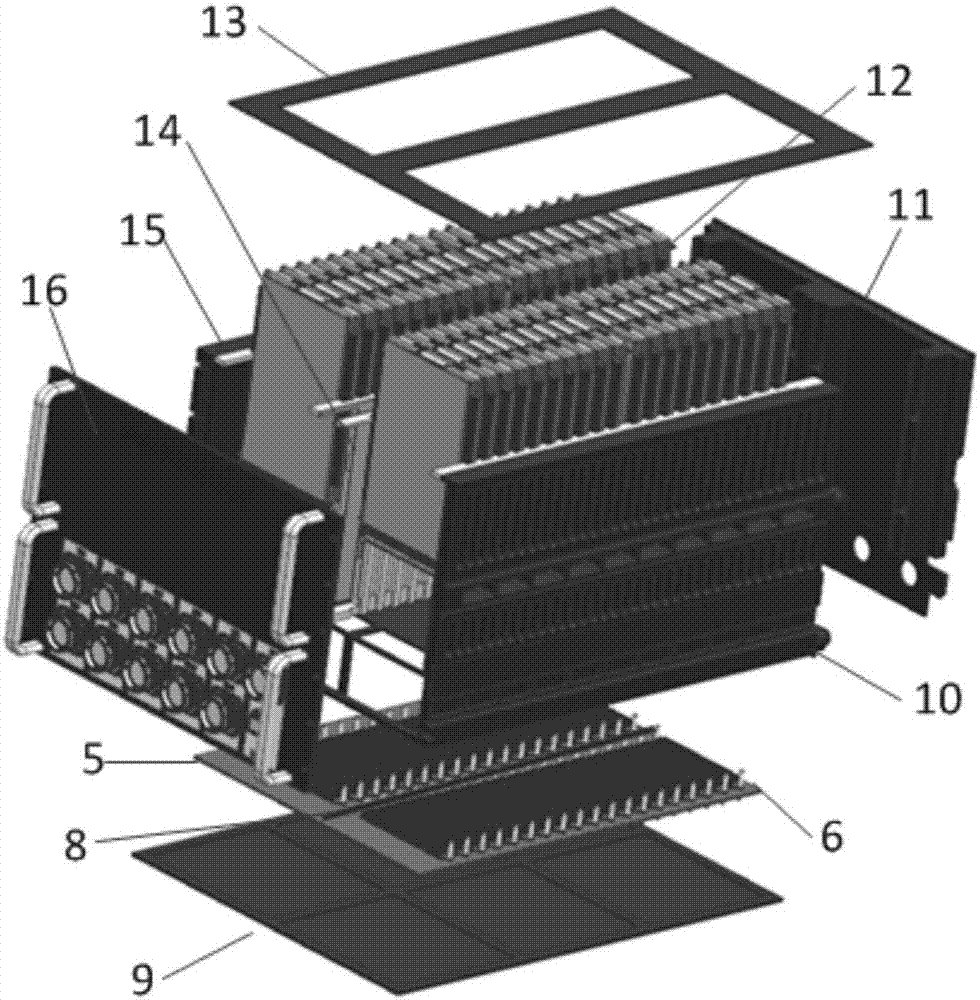

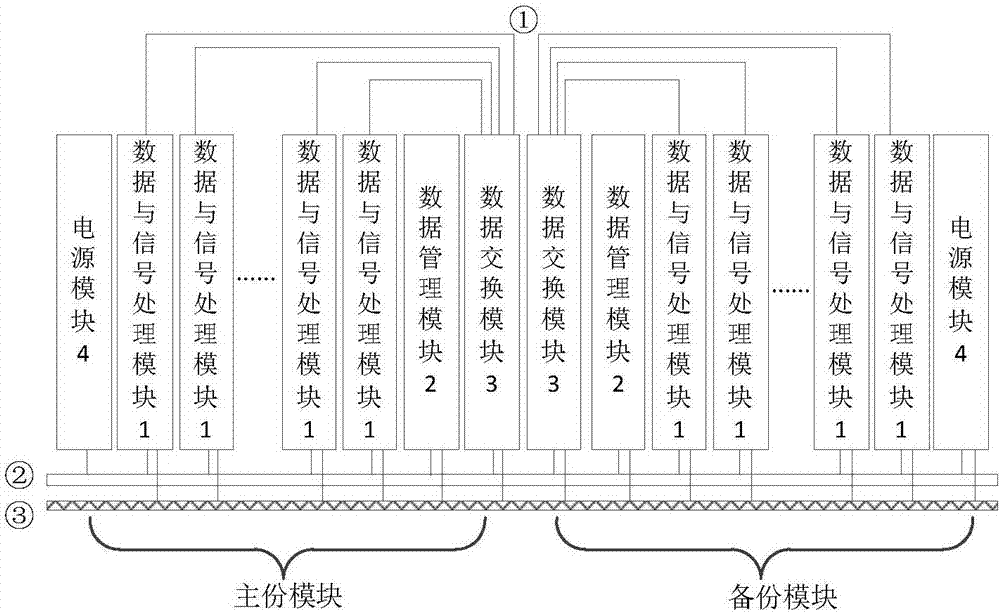

[0018] refer to figure 1 . In the embodiment described below, an onboard electronic equipment backplane includes: a data management module 2, a data exchange module 3, a power supply module 4, a high-speed backplane 5, an expansion backplane 6, a chassis transfer module 7 and an expansion Connector 8, data and signal exchange bus ①, management bus ②, power bus ③.

[0019] On the high-speed backplane 5, the two data management modules 2 are centered on the two data exchange modules 3, respectively arranged in parallel arrays on both sides of the two data exchange modules 3, and there are at least three parallel arrays on both sides of the two data exchange modules 3 The extended data and signal processing module 1 is extended to both ends; in the length direction of the expansion backplane 6, there are signal processing modules 1 in a parallel array with the same data as the number of the above-mentioned modules; the high-speed backplane 5 passes through 8 pairs of expansion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com