Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problem of inability to control the switching of semiconductor devices alone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

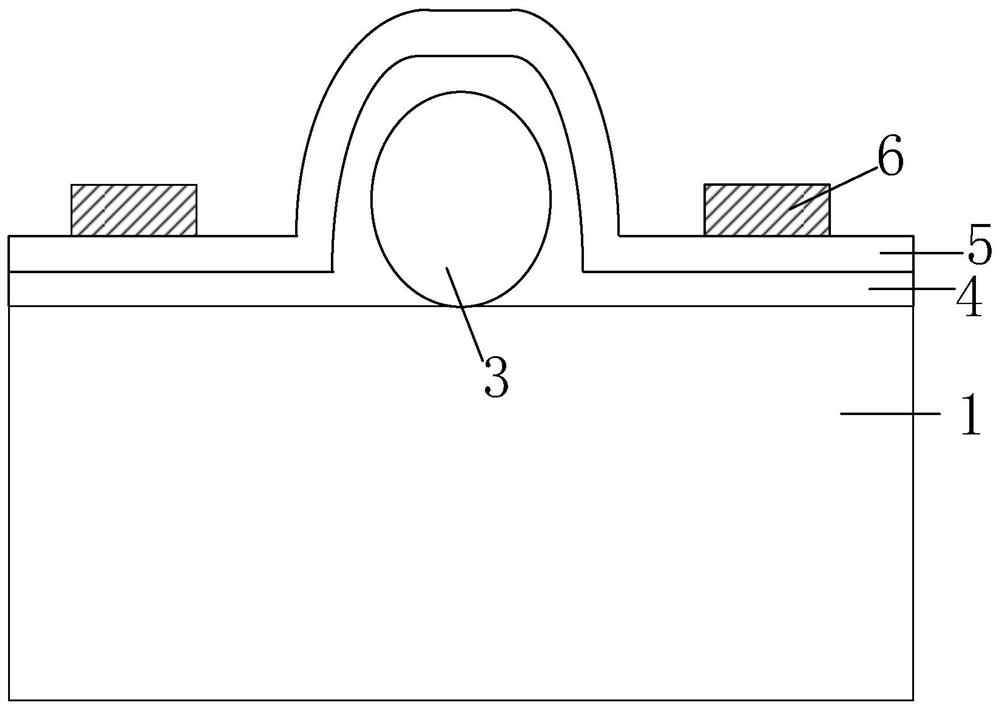

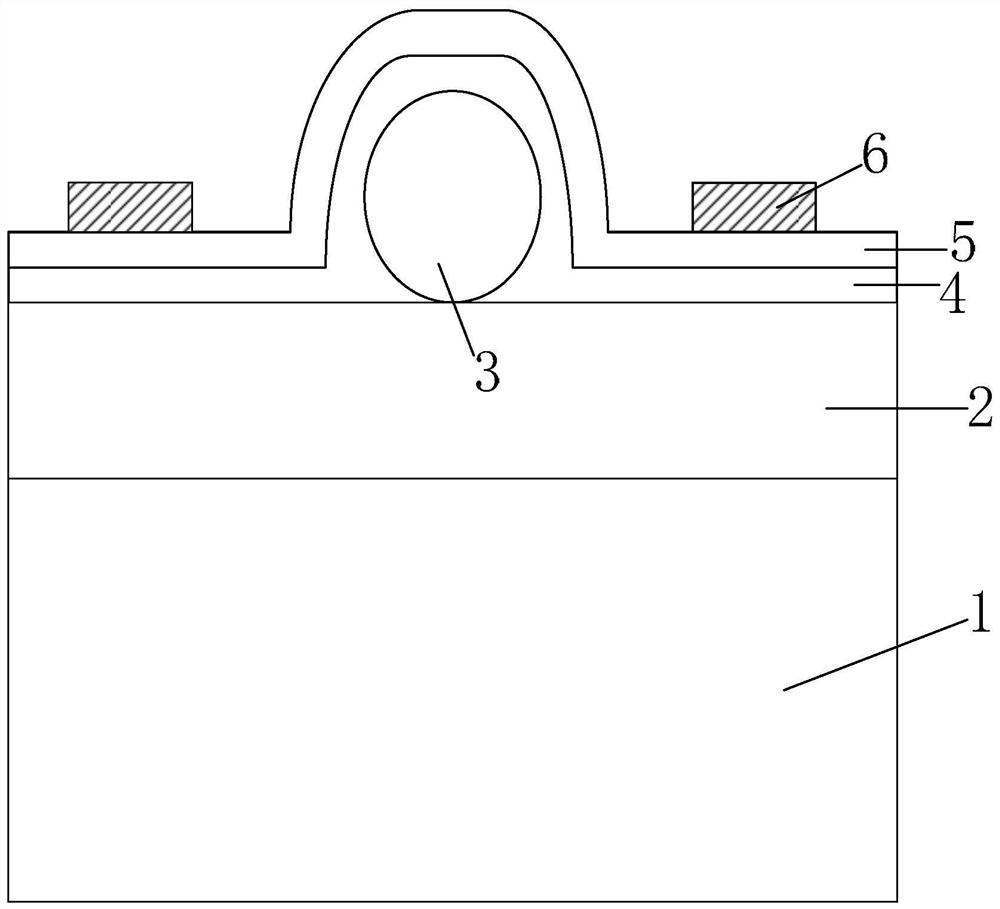

[0076] The specific travel process of semiconductor devices can be found in Figure 4 to Figure 10 . Specifically, the formation process includes:

[0077] First, a nanowire back gate is provided on a part of the surface of the substrate 1 .

[0078] A substrate is provided, which is a silicon substrate, and silicon is deposited on the surface of the substrate 1 to form a back gate material layer 30; the back gate material layer 30 and the substrate 1 are etched, so that the substrate 1 is formed as Figure 4 The structure shown includes a first part and a second part protruding from the first part, and the etched back gate material layer 30 is formed Figure 4 The first pre-structure 31 shown has depressions on both side walls at the junction of the first pre-structure 31 and the substrate 1; wet oxygen oxidation is used to oxidize the first pre-structure 31 and the substrate 1, so that the surface layers of both Form a dense silicon oxide surface layer, that is, the forma...

Embodiment 2

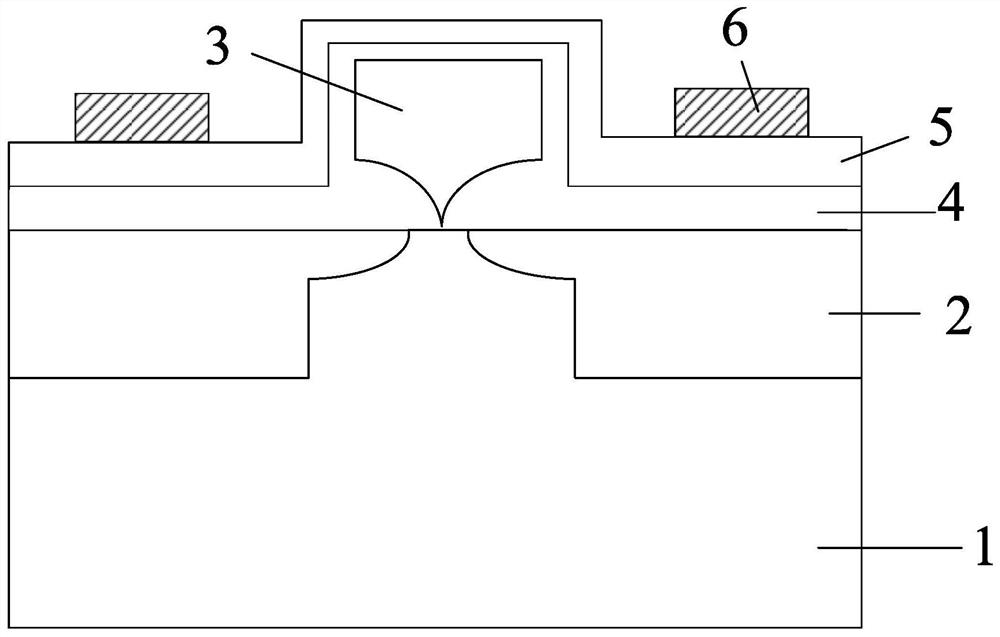

[0088] The specific travel process of semiconductor devices can be found in Figure 11 to Figure 15 . Specifically, the formation process includes:

[0089] First, a nanowire back gate is provided on a part of the surface of the substrate 1 .

[0090] A substrate 1 is provided, the substrate 1 is a silicon substrate, GeSi is deposited on the surface of the substrate 1 to form a sacrificial layer 13; silicon is deposited on the surface of the sacrificial layer 13 away from the substrate 1 to form a back gate material layer 30, Such as Figure 11 As shown; dry etching method is used to etch the sacrificial layer 13 and the back gate material layer 30 to form on the substrate 1 Figure 12 In the second pre-structure 32 shown, in fact, in the process of forming the back gate by etching, a support structure for supporting the back gate is formed at the same time, the support structure is located on both sides of the back gate and connected to the back gate, Figure 12 Not shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com