A combined carbon brush assembly for ct slip ring

A combined, carbon brush technology, applied in electrical components, rotating current collectors, current collectors, etc., can solve problems such as affecting normal use, small size of single-wire brushes, and disconnection of loop signals, and achieves easy inspection. and maintenance, reducing maintenance costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

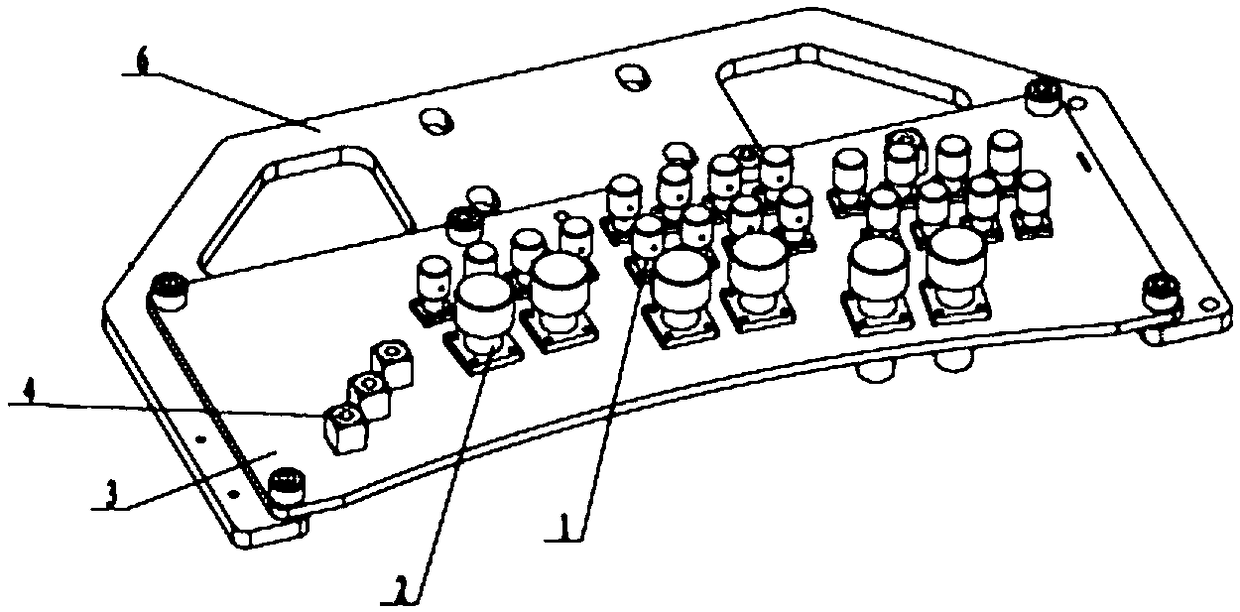

[0026] A combined carbon brush assembly for a CT slip ring, such as figure 1 As shown, it includes a signal brush assembly 1, a power brush assembly 2, a printed circuit board 3, a connection terminal 4 and a fixing plate 6,

[0027] The signal brush assembly 1, the power brush assembly 2, and the connection terminal 4 are all fixedly connected to the printed circuit board 3 through wave soldering, and the printed circuit board 3 is fixedly connected to the fixed plate 6;

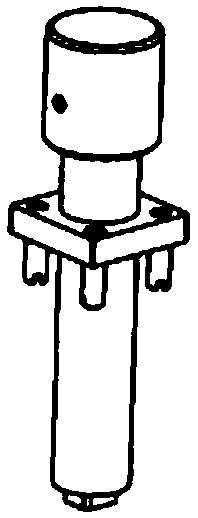

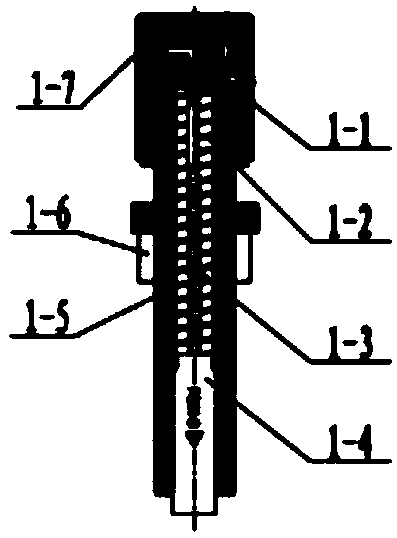

[0028] The signal brush assembly 1 and the power brush assembly 2 have the same structure, such as figure 2 , image 3 As shown, all include spring buckle 1-1, spring 1-2, brush braid 1-3, carbon brush 1-4, chute 1-5, terminal post 1-6 and knob 1-7,

[0029] One end of the brush braid 1-3 is fixedly connected to the carbon brush 1-4, the other end of the brush braid 1-3 is fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com