Three-phase load automatic balancing system in low voltage power supply area of transformer

A three-phase load, automatic balancing technology, applied in the direction of reducing the asymmetry of the polyphase network, eliminating/reducing the asymmetry of the polyphase network, etc., can solve the problems of increasing transformer losses, three-phase unbalance of rural grids, and increasing line losses. , to achieve the effect of reducing transformer loss, avoiding heat generation and aging, and reducing line loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention. These examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

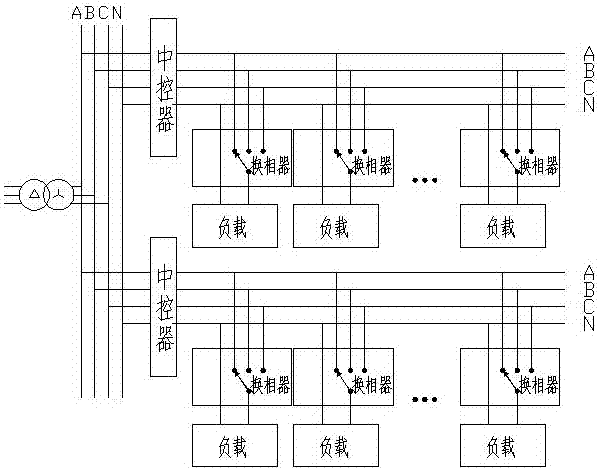

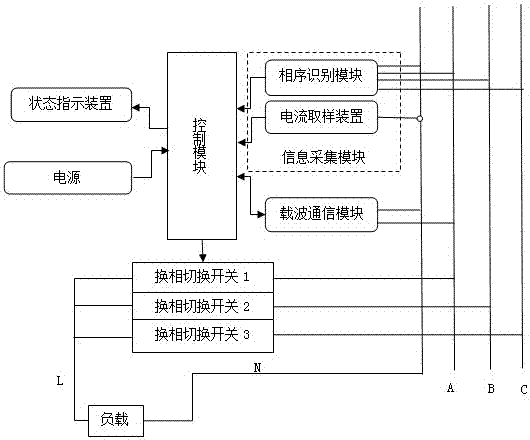

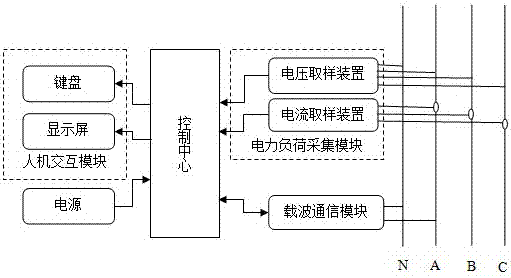

[0029] see Figure 1~3 , a three-phase load automatic balancing system for a low-voltage station area in a preferred embodiment of the present invention, including a central controller and a phase changer, the central controller is set on the main line in the station area, and the phase changer is located in the branch On the line, it is directly connected to the load. Both the central controller and the phase commutator are connected to the three-phase circuit in a three-phase four-wire system. The phase commutator monitors the current and voltage of its own load circuit in real time. size, the central controller monitors the unbalance degree of the main line in real time, and calculates the optimal leveling strategy in combination with the load size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com