Shock-absorbing damper with a spring plate fastened thereto, and method for the fastening of a spring plate to a shock-absorbing damper

A spring plate, damping technology, used in springs/shock absorbers, shock absorbers, springs, etc., can solve problems such as high capital expenditure, complex welding joints, etc., to achieve fast and cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

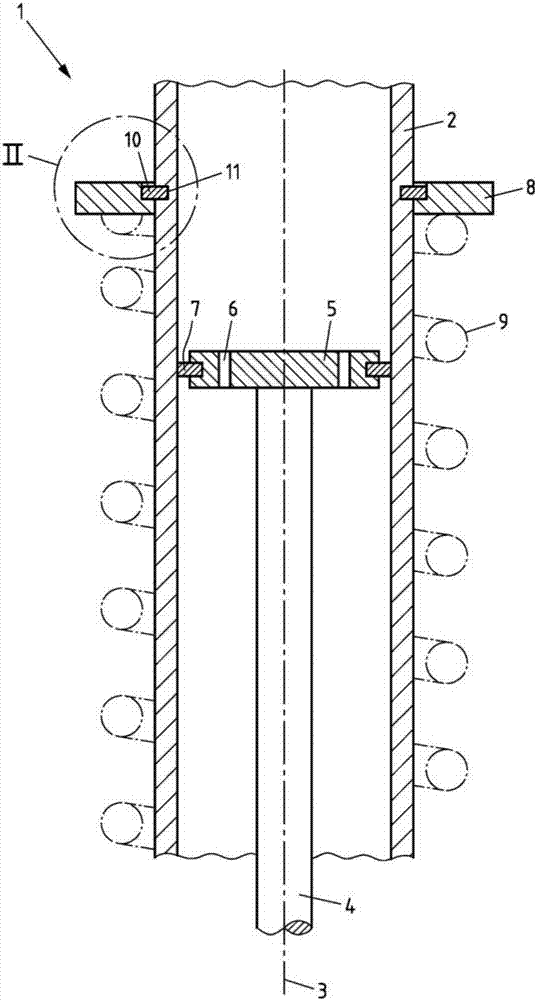

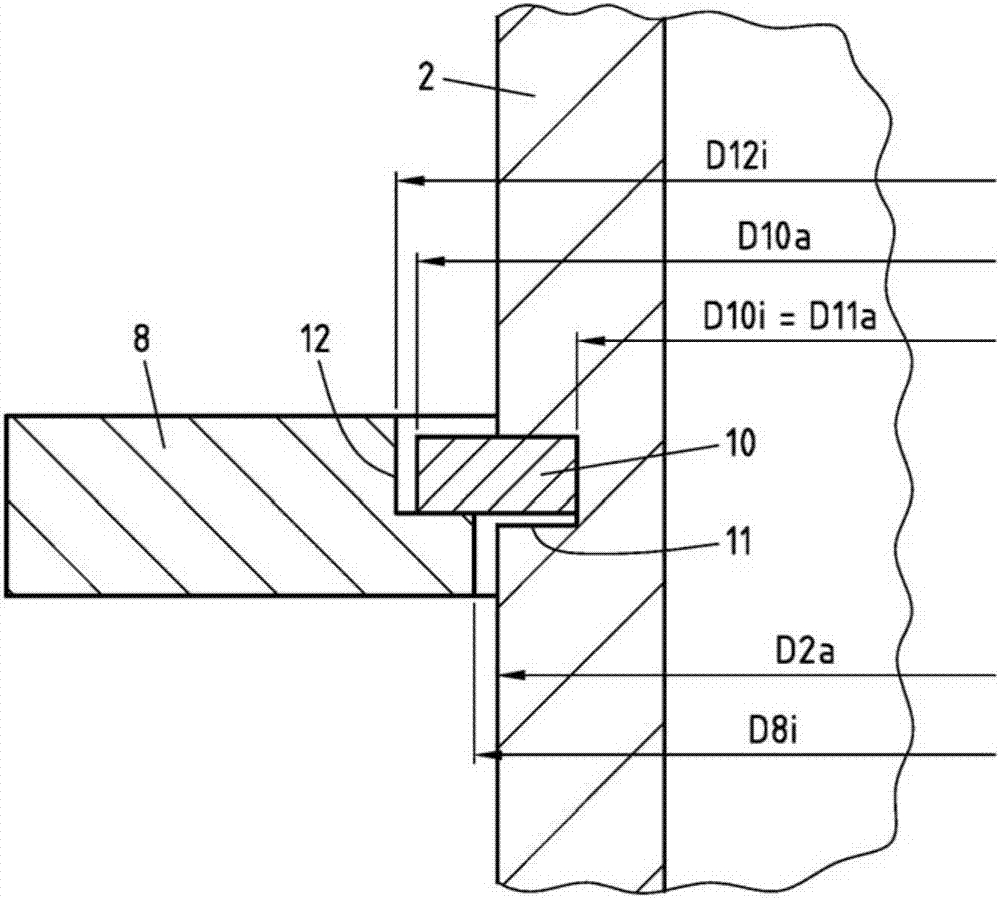

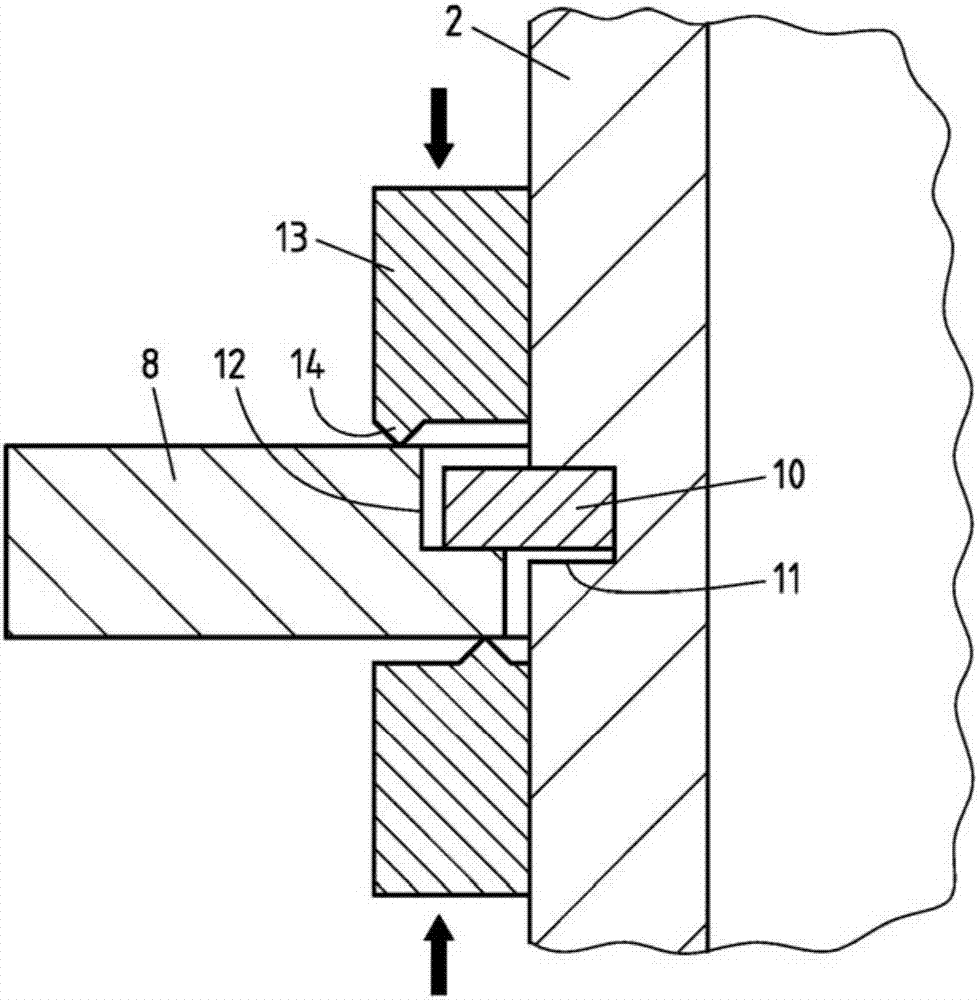

[0031] figure 1 A device 1 for damping vibrations according to the invention is shown. The device 1 comprises a damping tube 2 which is shaped like a cylinder and has a longitudinal axis 3 extending in the axial direction. Damping tube 2 is hollow and can receive liquid inside it (not in figure 1 shown in ), such as oil. The device 1 also includes a piston rod 4 at the lower end of which a piston 5 is fastened. The piston rod 4 is arranged centrally in the damping tube 2 and thus extends along the longitudinal axis 3 . The piston 5 has at least one piston valve 6 and a surrounding seal 7 . The seal 7 prevents the liquid present in the damping tube 2 from flowing through the piston 5 during its movement. Liquid can therefore only flow through the piston valve 6 so that the energy of the flow is converted into heat.

[0032] figure 1 The device 1 shown in also comprises a spring plate 8 of annular or disk-shaped design and extending around the damping tube 2 . The spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com