A kind of organic dye adsorption material and preparation method thereof

A technology for adsorbing materials and organic dyes, applied in the field of adsorbing dyes that fall off clothes during machine washing, and adsorbing materials, it can solve the problems of single type of adsorbed dyes, small amount of adsorption, and cross color, etc., to increase the surface adsorption energy, improve the Adsorption saturation, the effect of increasing affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

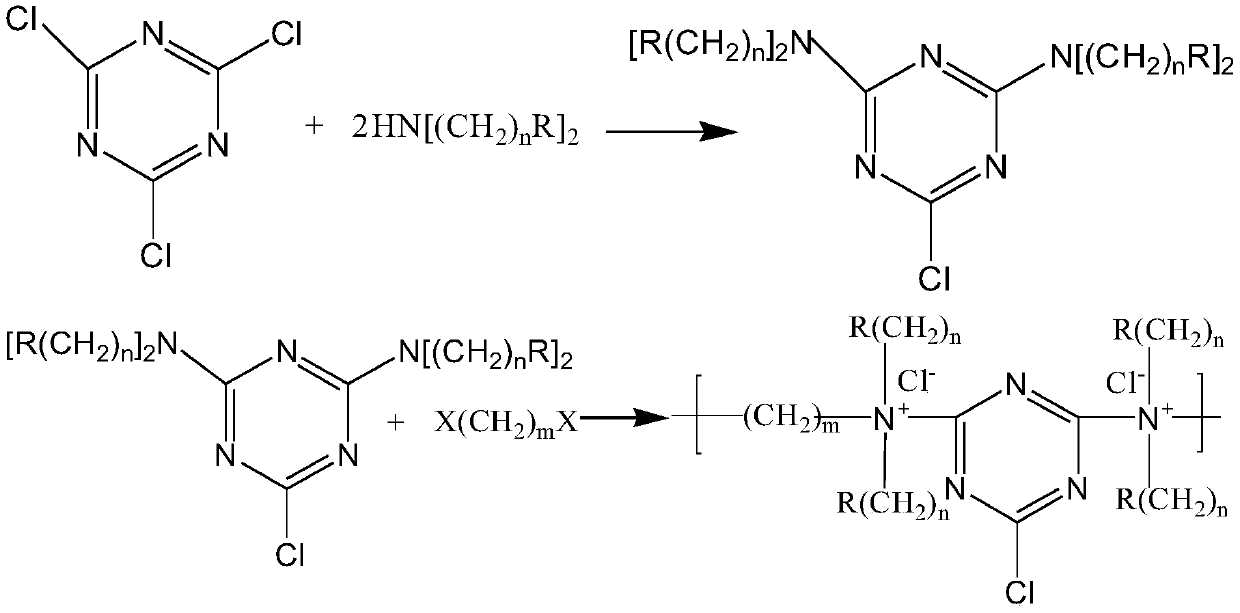

Method used

Image

Examples

Embodiment A

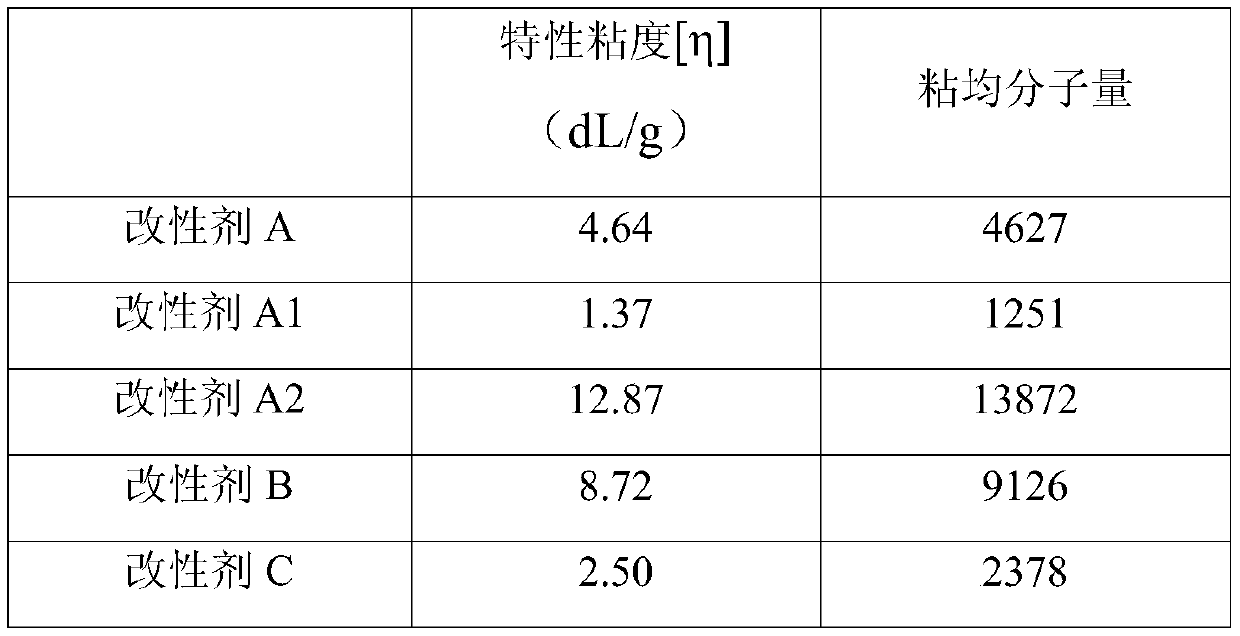

[0061] (1) Dissolve 10 mol of cyanuric chloride and 20 mol of diethanolamine in 5L of absolute ethanol, first stir and react at 0°C for 1.5h, then raise the temperature to 45°C and stir for 2h;

[0062] (2) After the reaction, when the temperature of the above reaction solution was lowered to room temperature, 11 mol of 1,4-dichloro-n-butane was added, stirred for 3 hours, filtered and dried to obtain Modifier A.

Embodiment B

[0070] (1) Dissolve 10 mol of cyanuric chloride and 20 mol of diethanolamine in 5L of absolute ethanol, first stir and react at 0°C for 1.5h, then raise the temperature to 45°C and stir for 2h;

[0071] (2) After the reaction is finished, when the temperature of the above reaction solution is lowered to room temperature, add 10.5 mol of 1,4-dichloro-n-butane, react with stirring for 3 hours, and filter and dry to obtain modifier B.

Embodiment C

[0073] (1) Dissolve 10 mol of cyanuric chloride and 20 mol of diethanolamine in 5L of absolute ethanol, first stir and react at 0°C for 1.5h, then raise the temperature to 45°C and stir for 2h;

[0074] (2) After the reaction, when the temperature of the above reaction solution was lowered to room temperature, 12 mol of 1,4-dichloro-n-butane was added, stirred for 3 hours, filtered and dried to obtain modifier C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com