Method of preparing sodium metatungstate solution based on bipolar membrane electrodialysis

A bipolar membrane electrodialysis and sodium metatungstate technology, applied in electrodialysis, chemical instruments and methods, membrane technology, etc., can solve the problems of high energy consumption and large equipment investment, and achieve low energy consumption and high tungsten yield. , to ensure high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

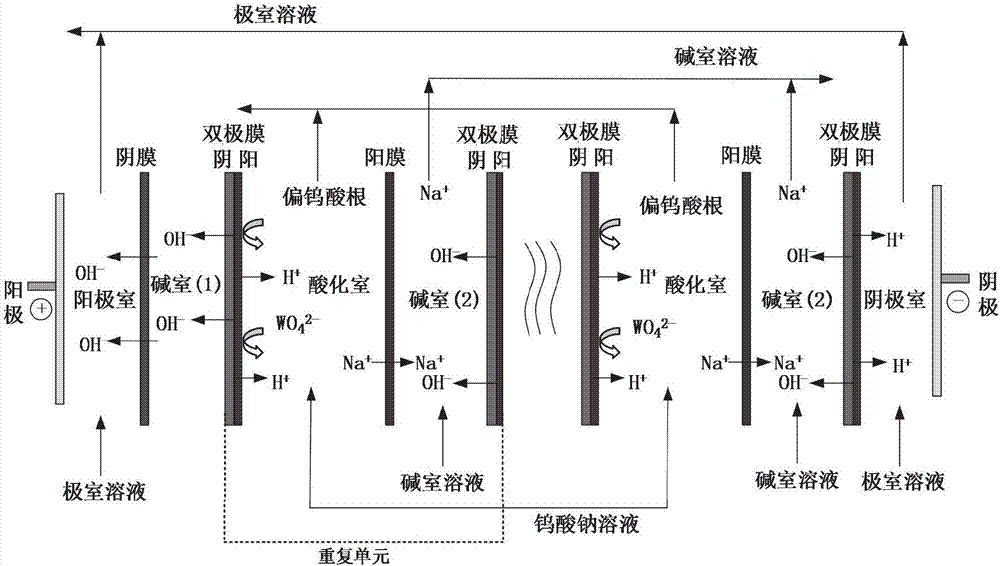

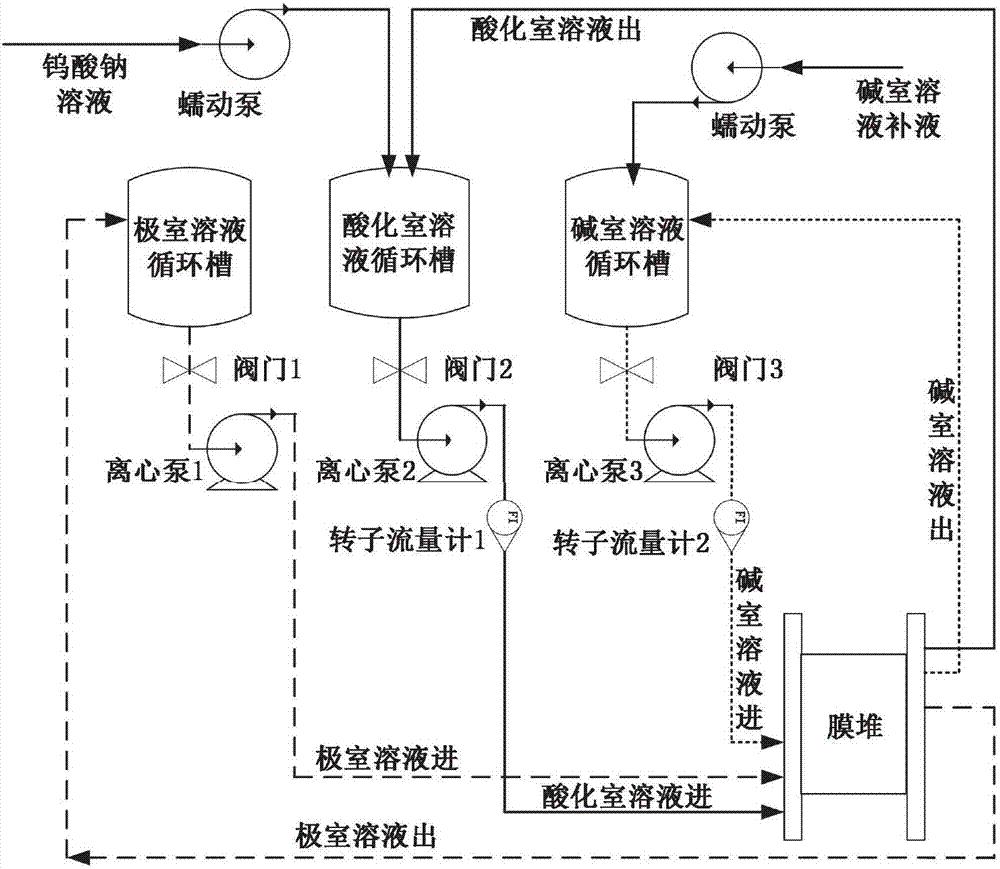

[0065] Using a basic structure such as figure 2 In the electrodialysis system shown, the membrane stack of the electrodialyzer includes 20 two-chamber units, and the effective area of a single membrane is 0.02m 2 , the bipolar membrane is NEOSEPTA BP-1, the cation exchange membrane is NEOSEPTA CMB, the anode and cathode are both titanium-plated nickel-plated electrodes, and the membrane stack structure is as follows figure 1shown. Sodium tungstate solution containing WO 3 252g / L. The solution initially filled into the circulation tank of the acidification chamber is sodium metatungstate solution, where WO 3 300.8g / L, pH value around 3.2, volume 6.0L. The solution initially filled into the circulation tank of the alkali chamber is NaHCO 3 solution with a concentration of 1.0 mol / L and a volume of 5 L. The solution continuously added to the alkali chamber is 1.0mol / L NaHCO 3 solution. The solution initially filled into the circulation tank of the electrode chamber is ...

Embodiment 2

[0067] Using a basic structure such as figure 2 The electrodialysis system shown, wherein the membrane stack of the electrodialyzer is the same as that of embodiment 1. Sodium tungstate solution containing WO 3 150.1g / L,. The solution initially filled into the circulation tank of the acidification chamber is obtained by diluting the sodium metatungstate solution prepared in Example 1 with deionized water, wherein WO 3 145.2g / L, pH value around 2.0, volume 6.0L.

[0068] The solution initially filled into the circulation tank of the alkali chamber is Na 2 CO 3 solution with a concentration of 0.1mol / L and a volume of 5L. The solution to be continuously added to the alkali chamber is also Na with a concentration of 0.1mol / L 2 CO 3 solution. The solution initially filled into the circulation tank of the electrode chamber is NaOH solution with a concentration of 1.0 mol / L and a volume of 5 L. After the power-on operation starts, the sodium tungstate solution is continu...

Embodiment 3

[0070] The equipment used is the same as that of Example 1, except that the cathode and anode are platinum-plated titanium plate electrodes. Sodium tungstate solution containing WO 3 98.9g / L. The solution initially filled into the circulation tank of the acidification chamber is obtained by diluting the sodium metatungstate solution prepared in Example 2 with deionized water, wherein WO 3 51.1g / L, pH value around 4.0, volume 6.0L. The solution initially filled into the circulation tank of the alkali chamber is NaOH solution with a concentration of 0.5mol / L and a volume of 5L. The solution to be continuously added to the alkali chamber is NaOH solution with a concentration of 0.5mol / L. The solution initially filled into the circulation tank of the electrode chamber is NaOH solution with a concentration of 1.0 mol / L and a volume of 5 L. After the electrodialysis operation starts, the sodium tungstate solution is continuously added to the inlet pipeline of the acidification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com