A kind of ink for making active layer, preparation method and application

A technology of active layer and ink, applied in the field of active layer, can solve problems such as inability to realize patterning, large equipment size, and unsuitable for miniaturized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The second aspect of the present disclosure provides a method for preparing an ink for making an active layer of a flexible organic photovoltaic device, which includes: poly(3-hexylthiophene) and [6,6]-phenyl C 71 Methyl butyrate is mixed with an organic solvent to obtain an ink; wherein, the concentration of poly(3-hexylthiophene) in the ink is 10-30 mg / mL, and the [6,6]-phenyl C 71 The concentration of methyl butyrate is 10-45mg / mL; preferably, the concentration of poly(3-hexylthiophene) in the ink is 15-25mg / mL, and the [6,6]-phenyl C 71 The concentration of methyl butyrate is 25-35mg / mL; more preferably, the concentration of poly(3-hexylthiophene) in the ink is 20mg / mL, and the [6,6]-phenyl C 71 The concentration of methyl butyrate was 30 mg / mL.

[0028] According to the second aspect of the present disclosure, the method for dissolving poly(3-hexylthiophene) and [6,6]-phenyl C 71The organic solvent of methyl butyrate is well known to those skilled in the art, can...

Embodiment 1

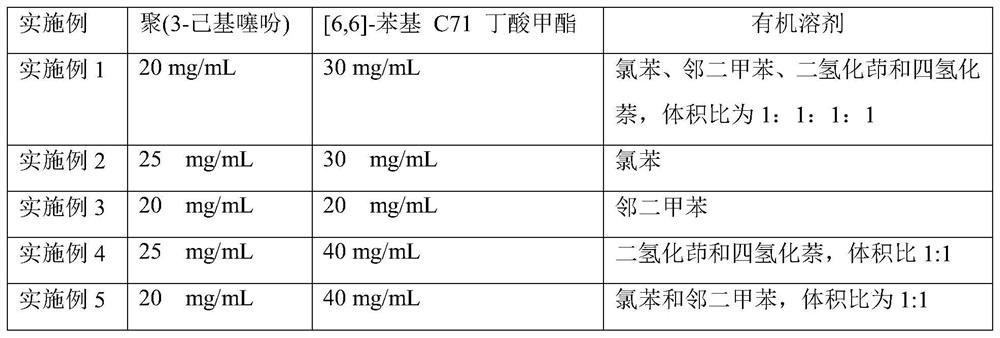

[0038] Weigh 20mg of poly(3-hexylthiophene) and 30mg of [6,6]-phenyl C 71 methyl butyrate, and dissolved it in 1mL mixed solvent to obtain ink, the specific composition is shown in Table 1. The mixed solvent is a mixture of chlorobenzene, o-xylene, indane and tetralin with a volume ratio of 1:1:1:1.

[0039] Put the ink into the ink cartridge, and use the inkjet printer to stably eject ink droplets. The specific performance of the ink is shown in Table 2. The active layer made of this ink can meet the use standard.

Embodiment 2-5

[0041] The preparation steps of Example 2-5 are basically the same as those of Example 1. The specific ink composition is shown in Table 1, and the specific performance of the ink is shown in Table 2. The active layer made of the ink prepared in Example 2-5 can meet the use standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com