Comprehensive treatment and utilization method of precious metal-contained smelting wastes

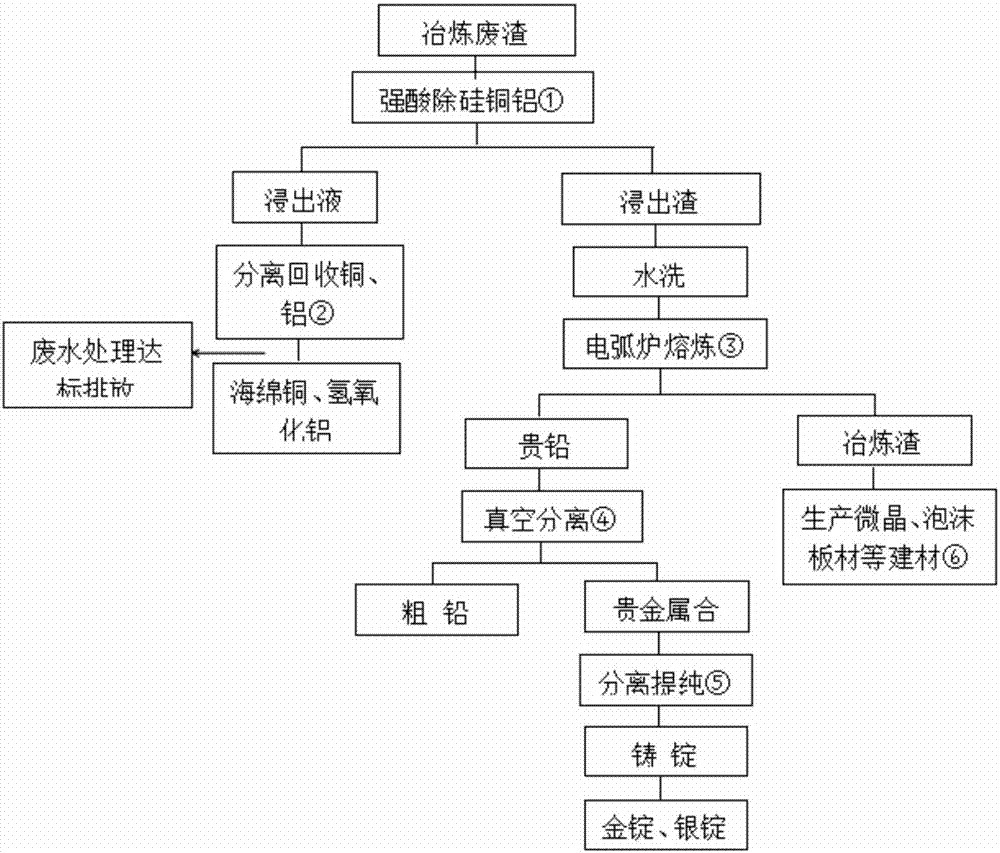

A precious metal and smelting slag technology is applied in the field of comprehensive treatment and utilization of precious metal-containing smelting slag, which can solve the problems of waste slag generation, high consumption, low metal recovery rate, etc., and achieves the effect of high work efficiency and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A comprehensive treatment and utilization method for smelting waste residue containing precious metals, the method specifically includes the following steps:

[0028] ①Removal of silicon, copper and aluminum with strong acid: Dissolve the smelting waste residue containing precious metals in hydrochloric acid at a liquid-solid ratio of 8:1, and c(H + ) with a mass concentration of 15%, a dissolution temperature of 70°C, and stirring and dissolving for 3.5 hours to obtain leach residue and leachate;

[0029] ②Separation and recovery of copper and aluminum: A. Precipitating copper: add iron to the above leaching solution, the molar ratio of iron and copper is 1.2︰1, heat to a temperature of 70°C, react for 5 hours, and separate to obtain sponge copper; B. Precipitating aluminum: precipitating After the copper is finished, caustic soda is added to the leaching solution, the pH of the solution is adjusted to 6.5, and aluminum hydroxide is obtained by separation; the waste li...

Embodiment 2

[0035] A comprehensive treatment and utilization method for smelting waste residue containing precious metals, the method specifically includes the following steps:

[0036] ① Removal of silicon, copper and aluminum with strong acid: the smelting waste residue containing precious metals is dissolved in sulfuric acid at a liquid-solid ratio of 4:1, and the c(H + ) with a mass concentration of 40%, a dissolution temperature of 55°C, and stirring and dissolving for 4.5 hours to obtain leaching residue and leaching liquid;

[0037] ②Separation and recovery of copper and aluminum: A. Copper precipitation: Add iron to the above leaching solution, the molar ratio of iron to copper is 1.2︰1, heat to 80°C, react for 3.5 hours, and separate to obtain sponge copper; B. Aluminum precipitation: After the copper precipitation is completed, caustic soda is added to the leaching solution to adjust the pH of the solution to 6.5, and aluminum hydroxide is obtained by separation; the waste liqui...

Embodiment 3

[0043] A comprehensive treatment and utilization method for smelting waste residue containing precious metals, the method specifically includes the following steps:

[0044] ①Silicon, copper and aluminum removal with strong acid: the smelting waste residue containing precious metals is dissolved in sulfuric acid at a liquid-solid ratio of 6:1, and the c(H + ) with a mass concentration of 30%, a dissolution temperature of 65°C, and stirring and dissolving for 4 hours to obtain leach residue and leachate;

[0045] ②Separation and recovery of copper and aluminum: A. Precipitating copper: add iron to the above leaching solution, the molar ratio of iron and copper is 1.2︰1, heat to a temperature of 90°C, react for 3 hours, and separate to obtain sponge copper; B. Precipitating aluminum: precipitating After the copper is finished, caustic soda is added to the leaching solution, the pH of the solution is adjusted to 6.5, and aluminum hydroxide is obtained by separation; the waste liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com