Comprehensive Disposal and Utilization Method of Smelting Waste Slag Containing Precious Metals

A precious metal and comprehensive treatment technology, applied in the direction of improving process efficiency, etc., can solve the problems of waste slag generation, high cost consumption, low metal recovery rate, etc., and achieve the effect of high work efficiency and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

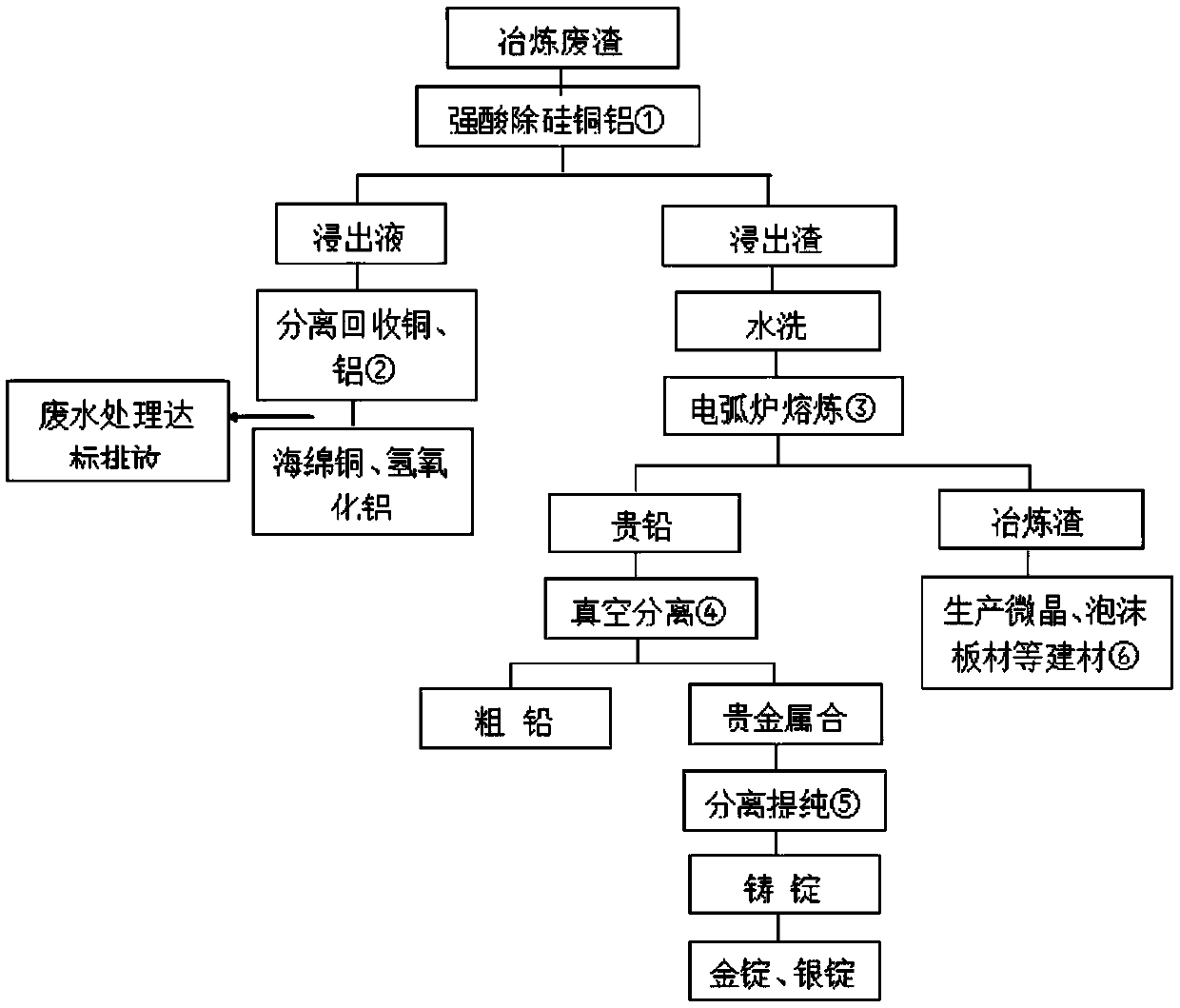

[0027] A comprehensive treatment and utilization method for smelting waste residue containing precious metals, the method specifically includes the following steps:

[0028] ①Removal of silicon, copper and aluminum with strong acid: Dissolve the smelting waste residue containing precious metals in hydrochloric acid at a liquid-solid ratio of 8:1, and c(H + ) with a mass concentration of 15%, a dissolution temperature of 70°C, and stirring and dissolving for 3.5 hours to obtain leach residue and leachate;

[0029] ②Separation and recovery of copper and aluminum: A. Precipitating copper: add iron to the above leaching solution, the molar ratio of iron and copper is 1.2︰1, heat to a temperature of 70°C, react for 5 hours, and separate to obtain sponge copper; B. Precipitating aluminum: precipitating After the copper is finished, caustic soda is added to the leaching solution, the pH of the solution is adjusted to 6.5, and aluminum hydroxide is obtained by separation; the waste li...

Embodiment 2

[0035] A comprehensive treatment and utilization method for smelting waste residue containing precious metals, the method specifically includes the following steps:

[0036] ① Removal of silicon, copper and aluminum with strong acid: the smelting waste residue containing precious metals is dissolved in sulfuric acid at a liquid-solid ratio of 4:1, and the c(H + ) with a mass concentration of 40%, a dissolution temperature of 55°C, and stirring and dissolving for 4.5 hours to obtain leaching residue and leaching liquid;

[0037] ②Separation and recovery of copper and aluminum: A. Copper precipitation: Add iron to the above leaching solution, the molar ratio of iron to copper is 1.2︰1, heat to 80°C, react for 3.5 hours, and separate to obtain sponge copper; B. Aluminum precipitation: After the copper precipitation is completed, caustic soda is added to the leaching solution to adjust the pH of the solution to 6.5, and aluminum hydroxide is obtained by separation; the waste liqui...

Embodiment 3

[0043] A comprehensive treatment and utilization method for smelting waste residue containing precious metals, the method specifically includes the following steps:

[0044] ①Silicon, copper and aluminum removal with strong acid: the smelting waste residue containing precious metals is dissolved in sulfuric acid at a liquid-solid ratio of 6:1, and the c(H + ) with a mass concentration of 30%, a dissolution temperature of 65°C, and stirring and dissolving for 4 hours to obtain leach residue and leachate;

[0045] ②Separation and recovery of copper and aluminum: A. Precipitating copper: add iron to the above leaching solution, the molar ratio of iron and copper is 1.2︰1, heat to a temperature of 90°C, react for 3 hours, and separate to obtain sponge copper; B. Precipitating aluminum: precipitating After the copper is finished, caustic soda is added to the leaching solution, the pH of the solution is adjusted to 6.5, and aluminum hydroxide is obtained by separation; the waste liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com